Mechanism for connecting two flanged pipe ends or tube ends

A technology for tubes and hoses, which is applied in the field of devices at the free ends of tubes or hoses, and can solve problems such as damage to clamps, self-opening of clamps, damage to the function of tubes or hose connectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

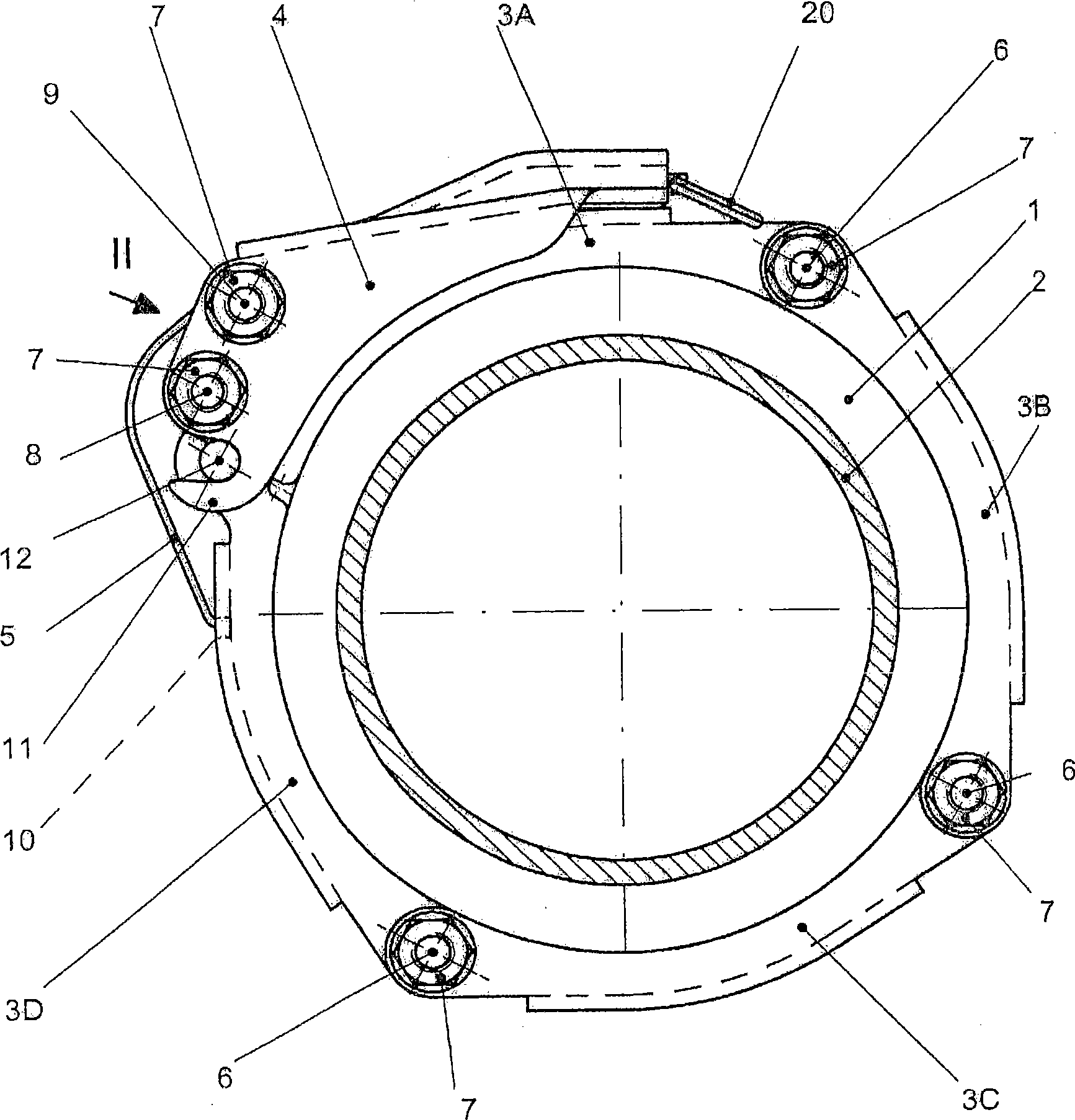

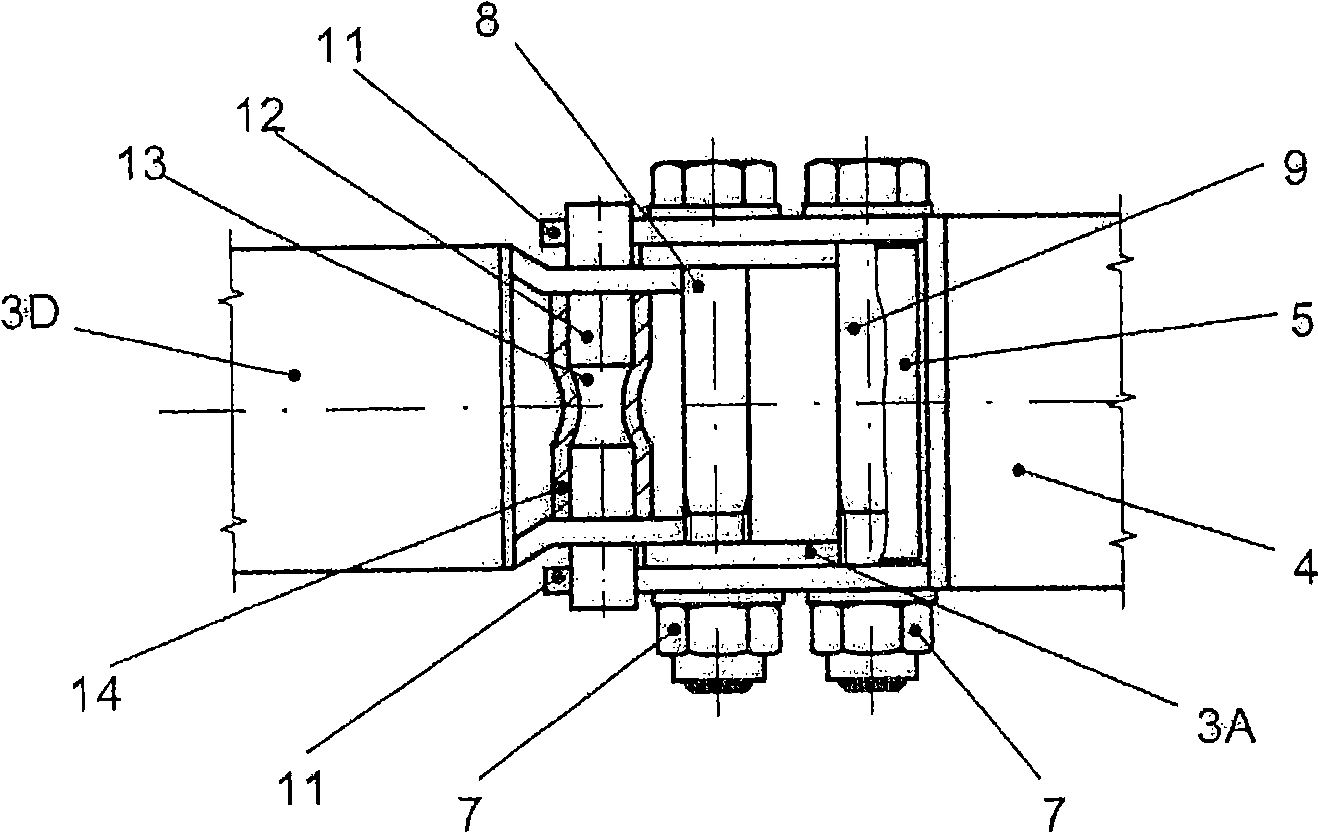

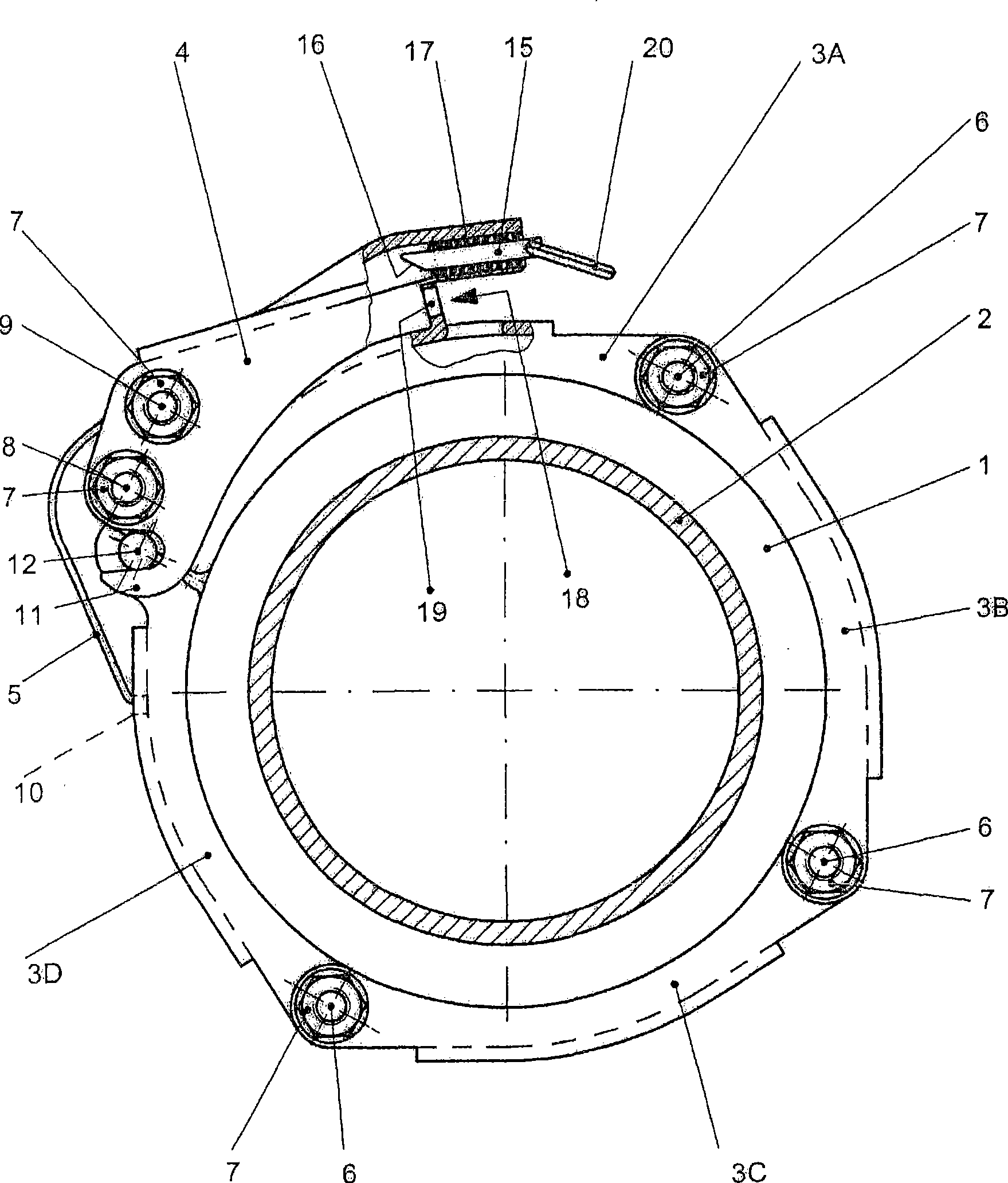

[0020] The connector shown in the drawings is a pipe connector for connecting two pipe ends 2 with flanges 1 . In the present exemplary embodiment, the device according to the invention consists of four mutually hinged clamp segments 3A, 3B, 3C, 3D and a locking mechanism consisting of a clamping lever 4 and a spring 5 .

[0021] The clamp segments 3A, 3B, 3C, 3D are hinged to one another by means of hinge bolts 6 which are screwed at their ends with nuts 7 . The clamping lever 4 is fastened to the free end of the clamp section 3A by means of a further pivot bolt 8 , and the other pivot bolt 9 is used to fasten one end of the spring 5 . The other end of the spring 5 is hooked into a recess 10 at the free end of the (opposite) clamp section 3D. Also tighten the hinge bolts 8 and 9 with the nut 7 .

[0022] Of course, the connecting clip of the present invention can also be composed of other numbers of clip segments. In the simplest case (as in the prior art) there are only t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com