Stone-glass element with capillary cut

A capillary and glass technology, applied in the direction of glass/slag layered products, building materials, manufacturing tools, etc., can solve problems such as stone-glass composite material hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

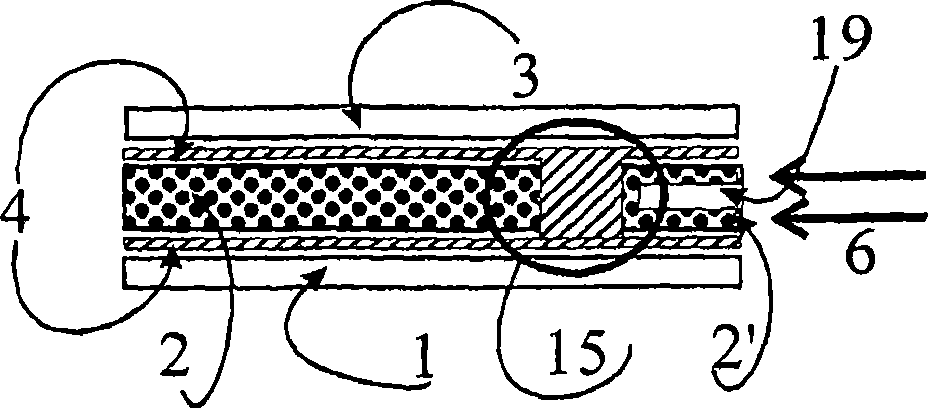

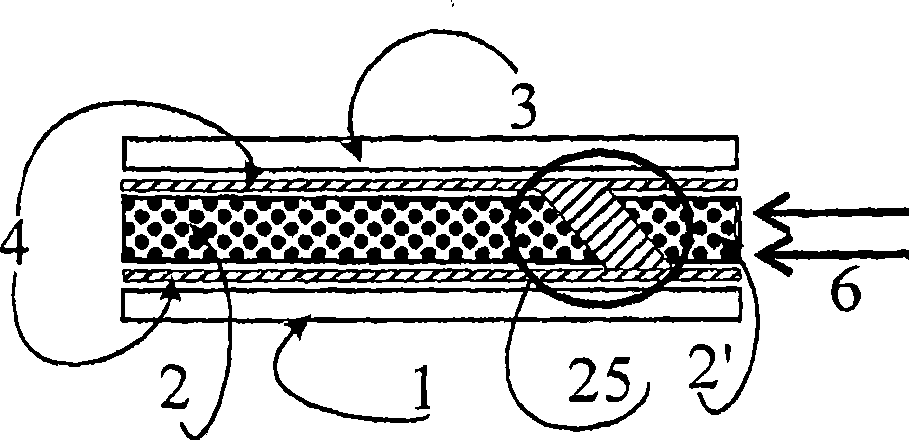

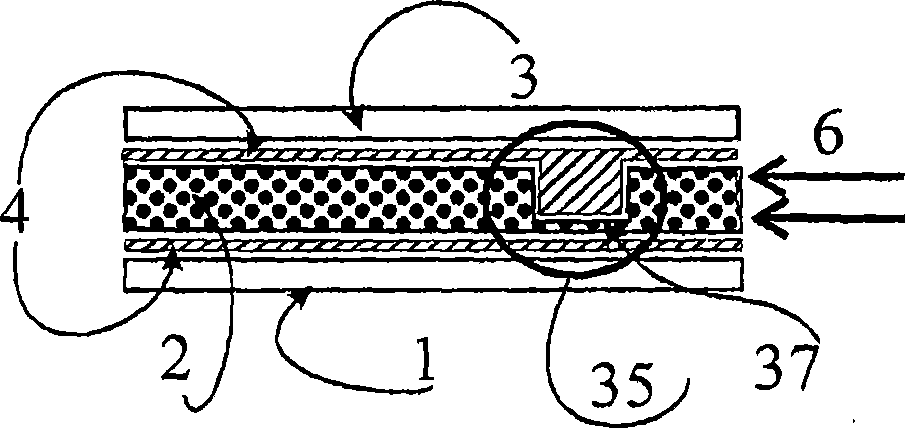

[0064] Figures 1 to 11 The cross-sectional views of each show the same principle structure of a stone-glass element with at least one stone plate 2 and a support plate 1 comprising at least one glass plate, which is passed through a A transparent or opaque cast resin layer 4 is attached over a large area to the stone slab 2 , wherein the surface of the stone slab 2 opposite the support slab 1 is provided with a moisture-proof layer or another cover 3 in the form of a plate. The areas drawn by circles or ellipses are shown respectively Figures 1 to 11 The design of different capillary cutouts. Moisture diffusion 6 acts on the cut surface shown exposed.

[0065] figure 1 A complete vertical capillary cut 15 is shown, which divides the stone. Here the cutout 19 shown horizontally for the remaining Figures 2 to 11 It is also representatively shown how the water uptake is further reduced in the edge strip formed by the capillary cutouts 15 and at the same time the drainage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com