Wire drawing machine drum rim manufacture technique

A manufacturing process and wire drawing machine technology, applied in the field of drum rims and their manufacturing processes, can solve problems such as unfavorable axial sliding of guide coils, overlapping winding of wires, production interruption, etc., and achieve the advantages of axial sliding, production cost reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

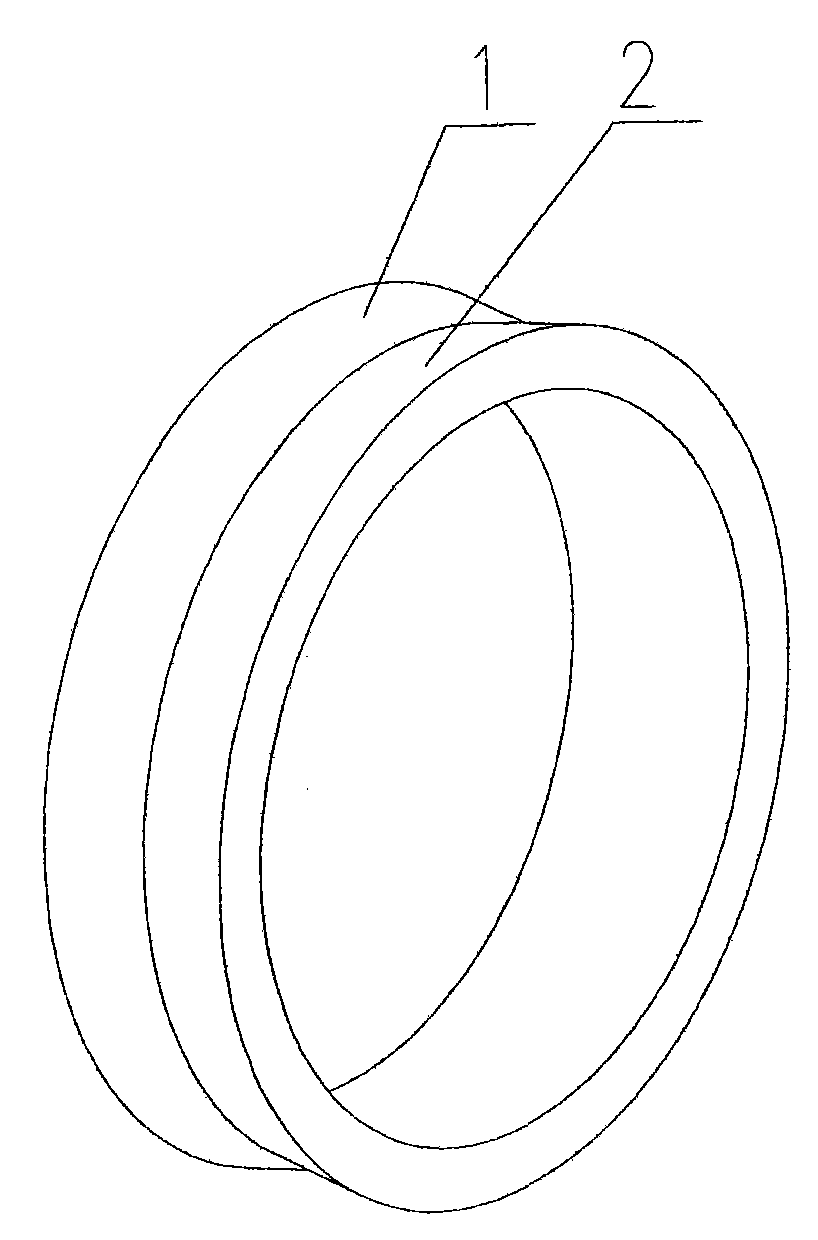

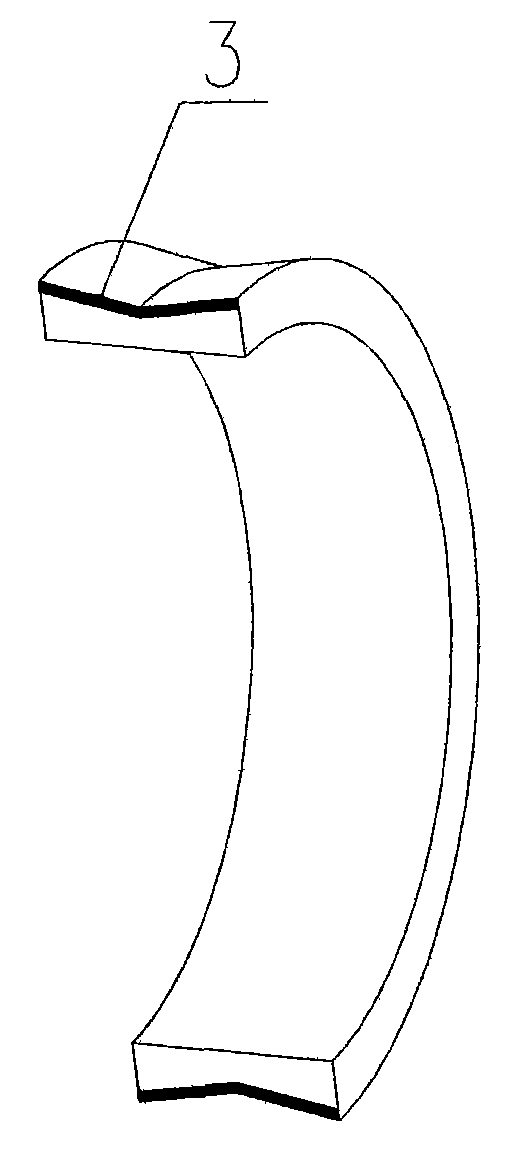

[0031] The structure of the rim of this drum see figure 2 , image 3 : Numbers 1 and 2 in the figure are the working surface structure of the outer circle of the drum rim. The working surface at the bottom of the groove is designed to be in a "V" shape, which is composed of two symmetrically arranged opposite slopes, and the two end surfaces are inclined to the middle along the axial direction. The structure forms two working surfaces 1 and 2, which not only facilitates the sliding of the wire when pulling the wire, reduces the friction and wear of the wire on the working surface, and prolongs the service life; but also when the working surface 1 is worn after a certain period of use , The drum rim can be removed from the drum seat and installed on the other side to use the working surface 2, the service life is more than doubled.

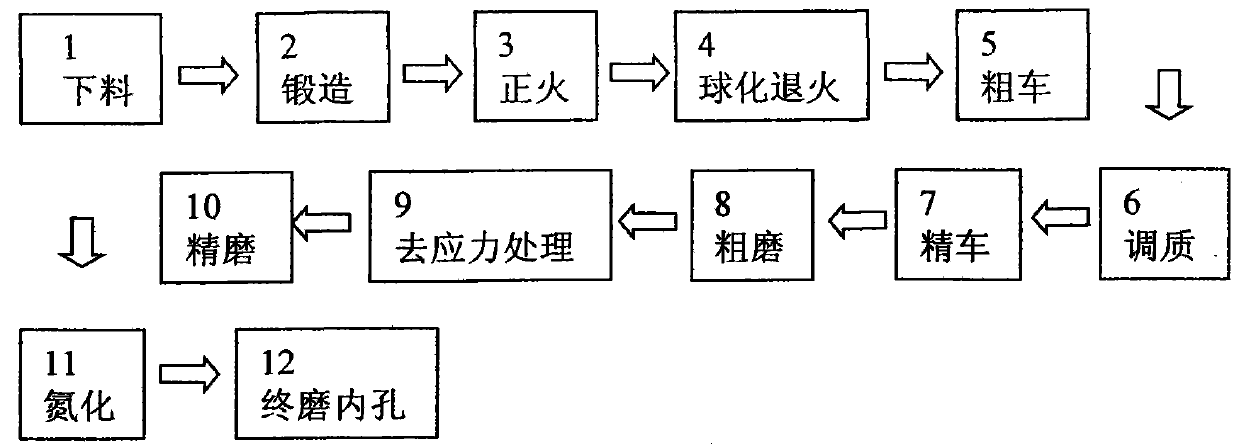

[0032] The drum rim is made of 38CrMoAlA, an alloy steel material with excellent nitriding performance. After quenching and tempering heat treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com