Cylinder manifold contact switching-on device for compensating cylinder manifold thickness

A technology of busbars and stop devices, applied in the direction of busbar/circuit layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

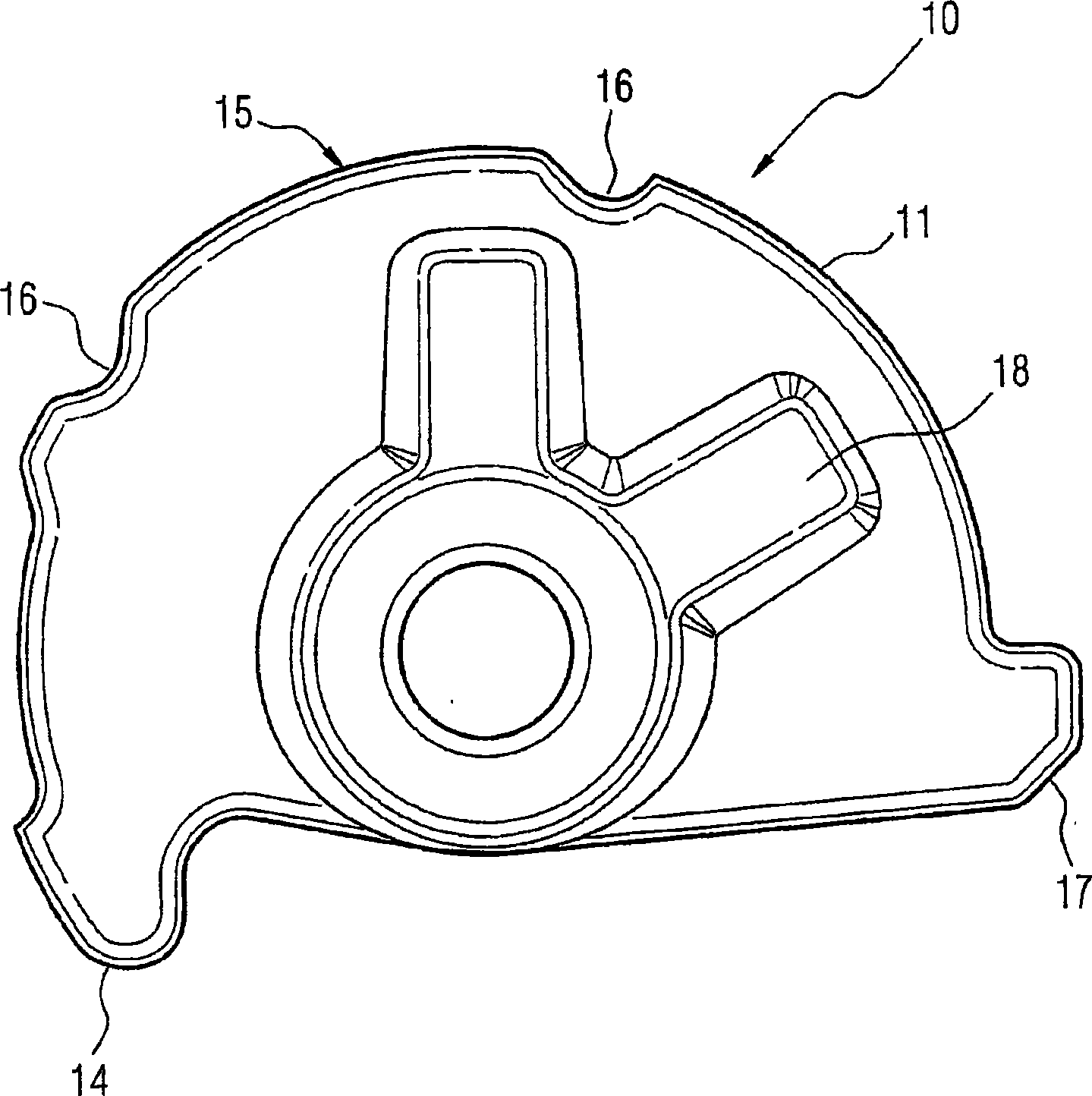

[0075] figure 1 A distance block 10 according to an embodiment is shown. The spacer 10 has a raised overall support edge 15 . The raised overall support edge 15 is interrupted by grooves 16 so that individual convex edges 11 are formed. Bosses 14 , 17 are located at the respective ends of the raised overall support leg 15 . For reinforcement, the spacer 10 has reinforcing ribs 18 which extend substantially radially from the center to the outside. The illustrated distance block 10 is circular segment-shaped. Of course, other embodiments are also possible for the spacer 10 , in which the spacer has an eccentrically convex overall support edge 15 or also a parabolic or exponentially shaped overall support edge 15 .

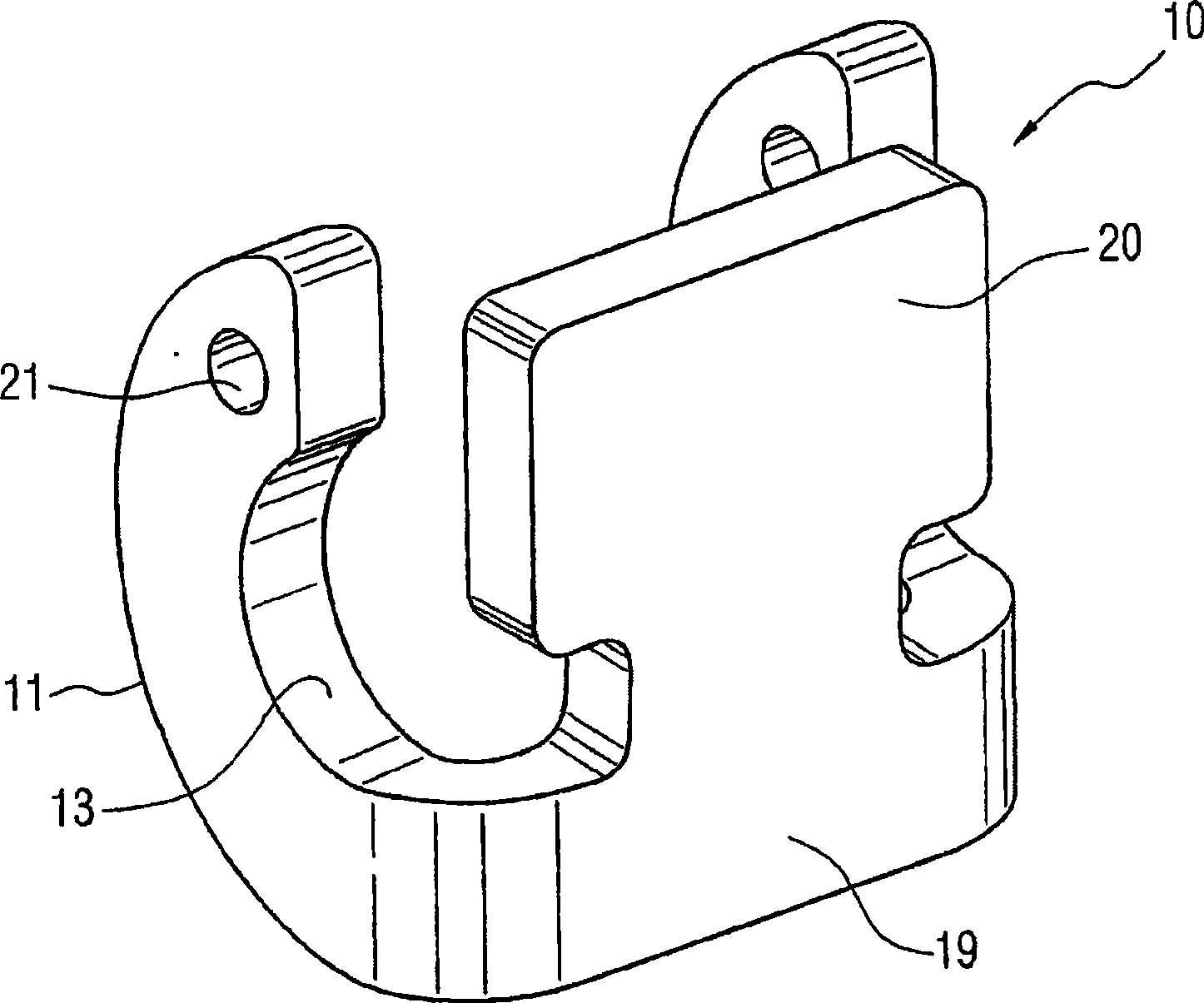

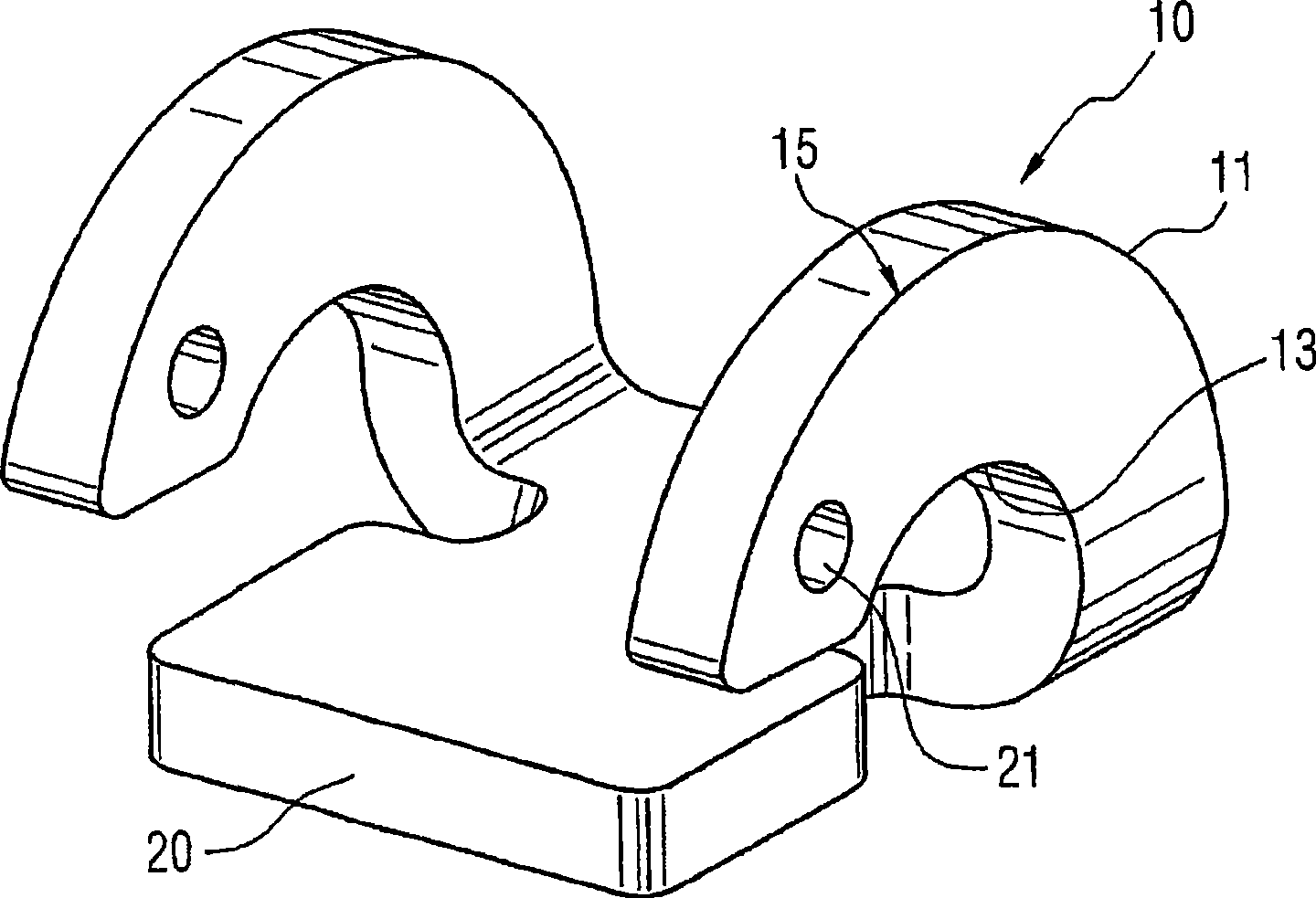

[0076] figure 2 and image 3 A distance block 10 according to another embodiment is shown. Such a spacer 10 has two convex sides 11 each arranged in a plane. Here, the planes in which the convex support edge 11 lies are parallel to one another. The two conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com