Hand crank for safe startup of single cylinder diesel

A diesel engine, safe technology, applied in the field of cranking hand device, can solve the problems that the cranking hand does not have the anti-reverse function, the shaking hand reverses and hurts people, and the reverse is easy to occur, and achieves the effect of eliminating the reversed wounding accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

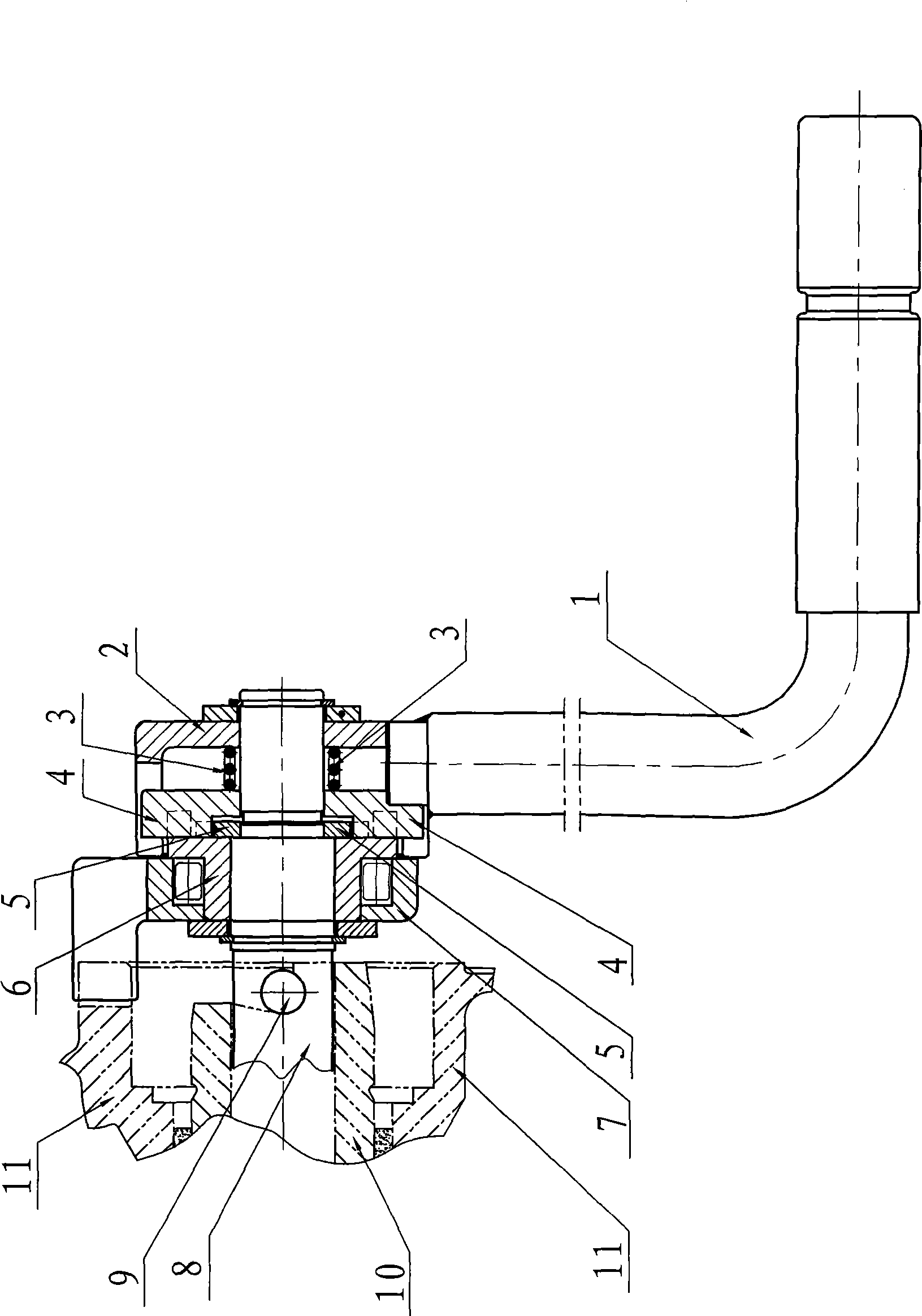

[0011] Embodiment 1: described single-cylinder diesel engine safe start rocker, such as figure 1 As shown, it includes a rocker 1, a rocker shell 2, a support spring 3, a coupling claw 4, a starting claw 5, a rotating sleeve 6, a one-way rotator 7, a rocker shaft 8, a cylindrical pin 9, a starting shaft 10, and a gear chamber cover 11 , the starting shaft 10 is set on the gear chamber cover 11, and an anti-reversal notch is provided on the end face of the gear chamber cover 11. The rocker 1 and the rocker shell 2 are fixed into one body, the rocker shell 2, the support spring 3, the coupling claw 4, The starting pawl 5, the rotating sleeve 6, and the cylindrical pin 9 are all installed on the rocker shaft 8, wherein the cylindrical pin 9 is fixedly mounted on the rocker shaft 8, and the rotating sleeve 6 is set on the rocking shaft 8 with gaps, on the left side of the rotating sleeve 6 It is limited by the shaft retaining ring and flat pad, and on its right side is axially lim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap