External anti-reversal starting device of single-cylinder diesel engine and use method thereof

A starting device and anti-reverse technology, applied to the starting device with manual crank, engine starting, machine/engine, etc., can solve the problems of large price increase, complicated assembly process, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

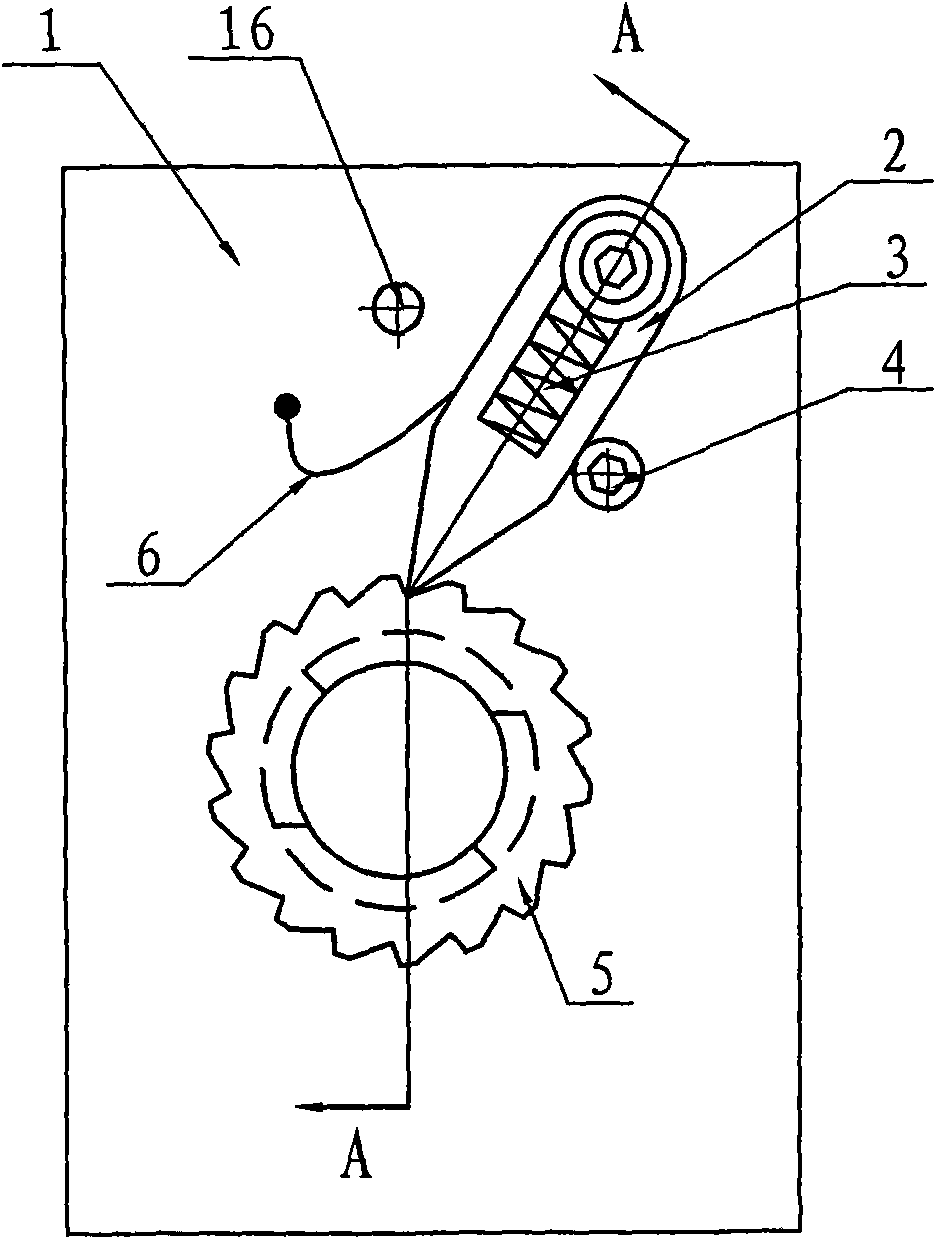

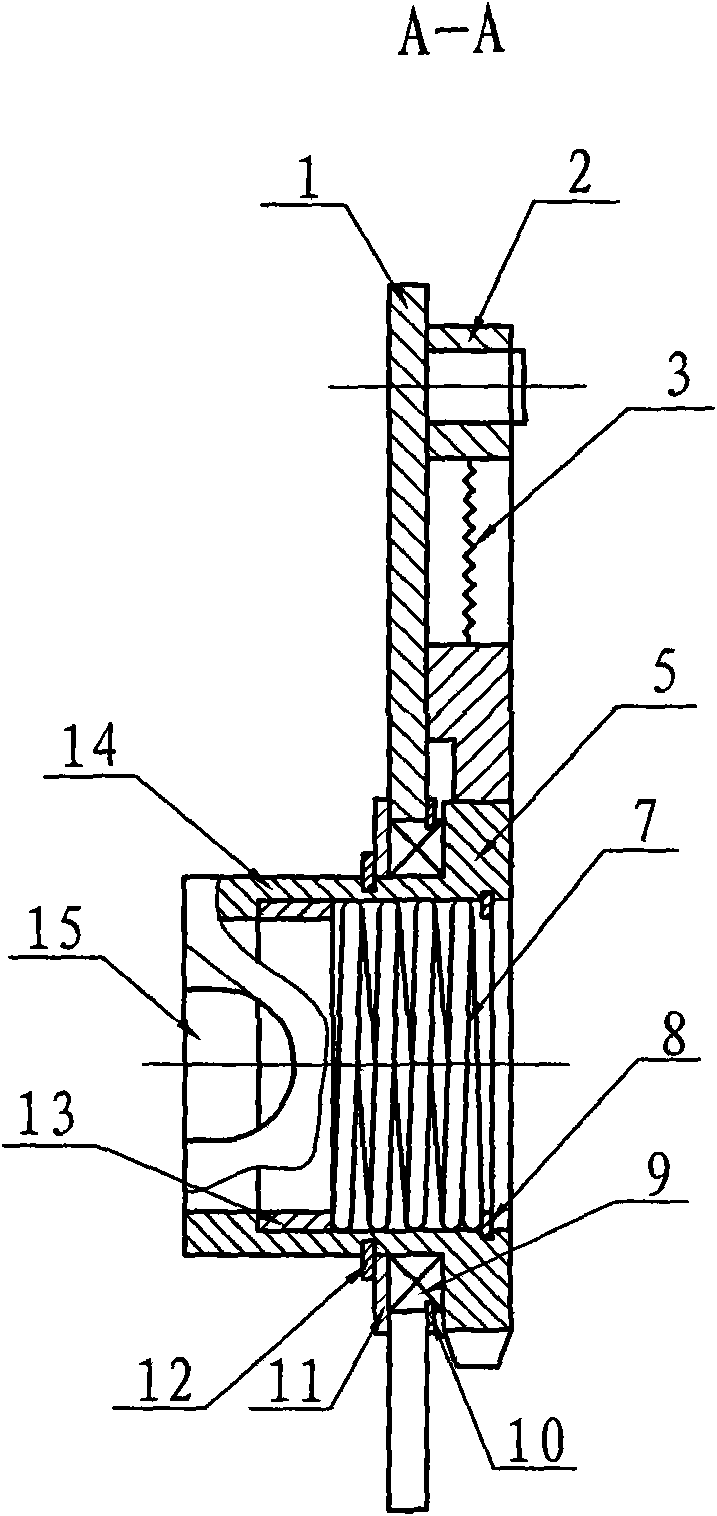

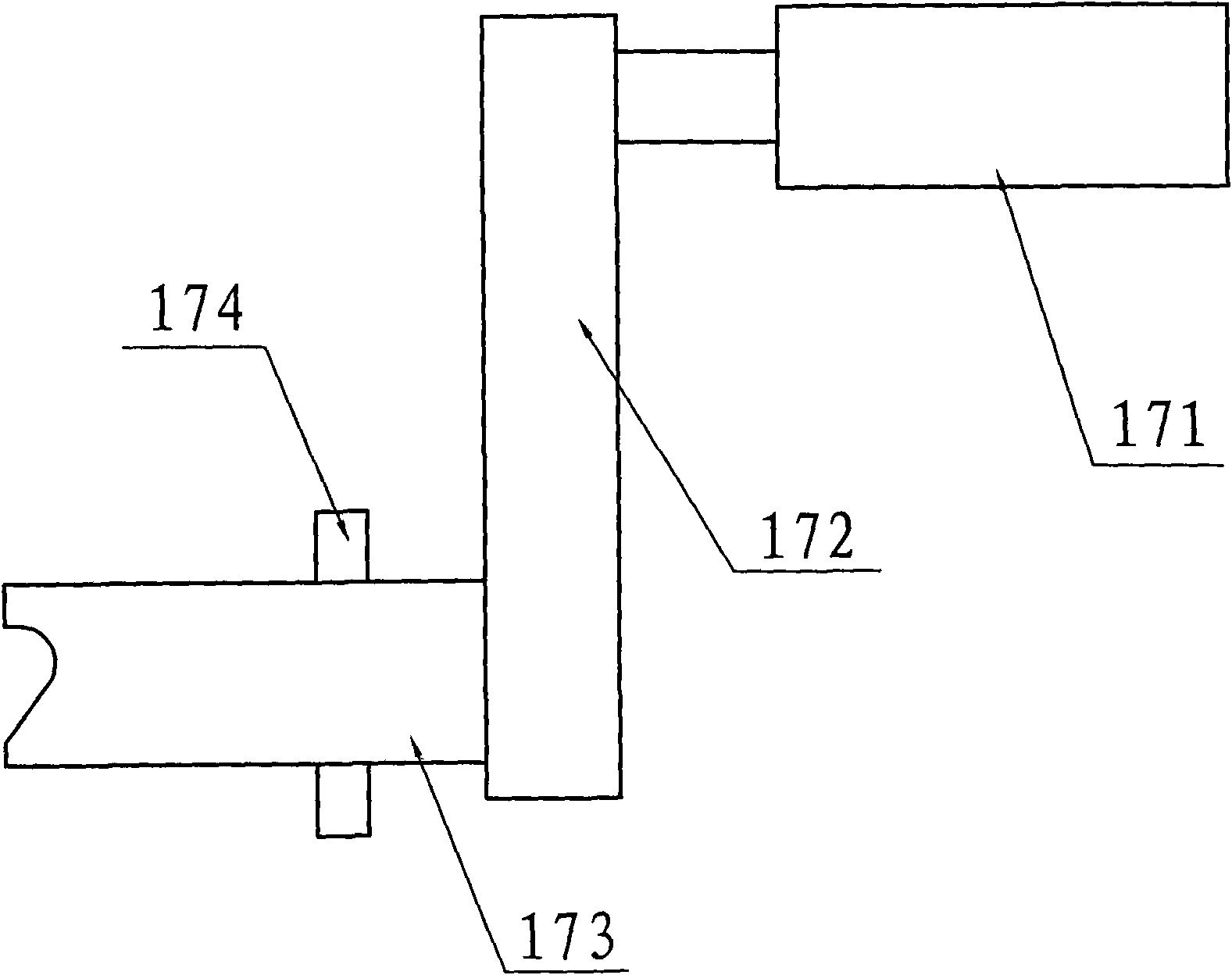

[0011] Embodiment 1: An external anti-reverse starting device for a single-cylinder diesel engine, such as figure 1 , figure 2 , image 3 As shown, it is composed of an anti-reverse starting seat and a starting shaker. The anti-reverse starting seat includes a connecting plate 1, a buffer claw 2, a buffer spring 3, a claw block 4, a spur wheel 5, a compression spring 6, Center spring 7, hole retaining ring 8, bearing 9, bearing collar 10, bearing stopper 11, shaft retaining ring 12, automatic detachment sleeve 13 and stab wheel sleeve shaft 14, stab wheel sleeve shaft 14 is connected with stab wheel 5 As a whole, the bearing 9 is installed on the shaft diameter of the junction of the ratchet sleeve shaft 14 and the ratchet 5, the outer ring of the bearing 9 is installed on the connecting plate 1, and the bearing 9 is composed of a bearing collar 10, a bearing stopper 11 and a shaft. The retaining ring 12 is axially limited, and the automatic disengagement sleeve 13 is arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap