Spiral-disc type variable-diameter shaft

A disc and helical technology, which is applied in the field of helical disc-type variable diameter shaft devices, can solve the problems of inconvenient operation, the inclination of the inclined plane should not be too large, and the pitch of the screw should not be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

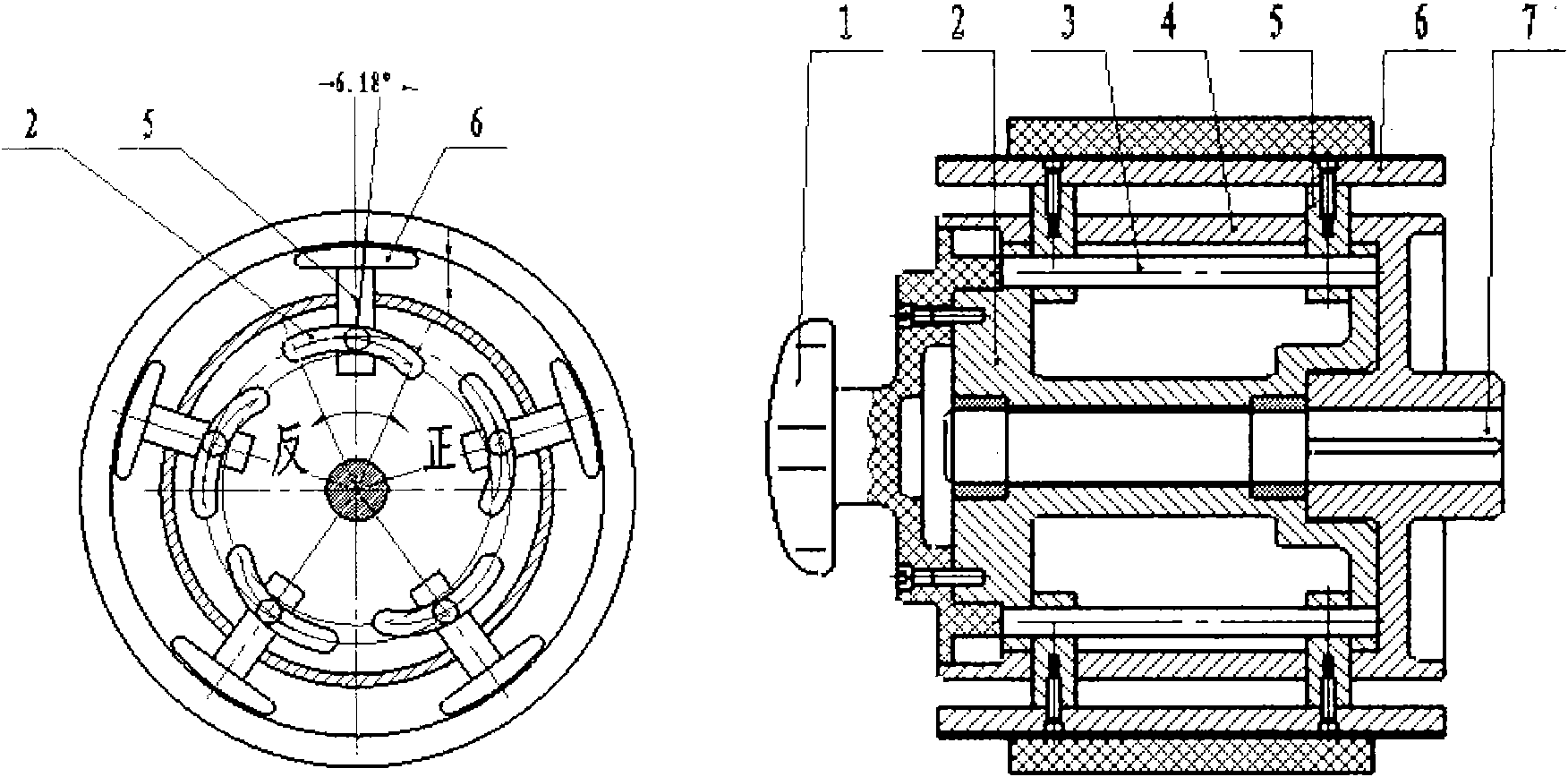

[0013] exist figure 1 In the shown embodiment, the rotary knob (1) fixed with the Archimedes spiral disk (2) by screws is used to make the Archimedes spiral disk (2) push the expansion tile (6) to move The way to realize the change of shaft diameter. In order to make the contact area between the shaft and the inner hole of the film roll as large as possible, in this example, 5 Archimedes spirals are evenly distributed, and the included angle of each Archimedes spiral is set to 60 degrees, so the expansion shaft is the largest Only need to rotate 60 degrees to make the shaft diameter change range up to 20mm. And control the maximum pressure angle to be less than 7 degrees to ensure that the pressure angle is less than or equal to the friction angle, so that rapid expansion can be achieved, and the problem of reverse self-locking of the expansion tile can be reliably guaranteed when the external force is removed.

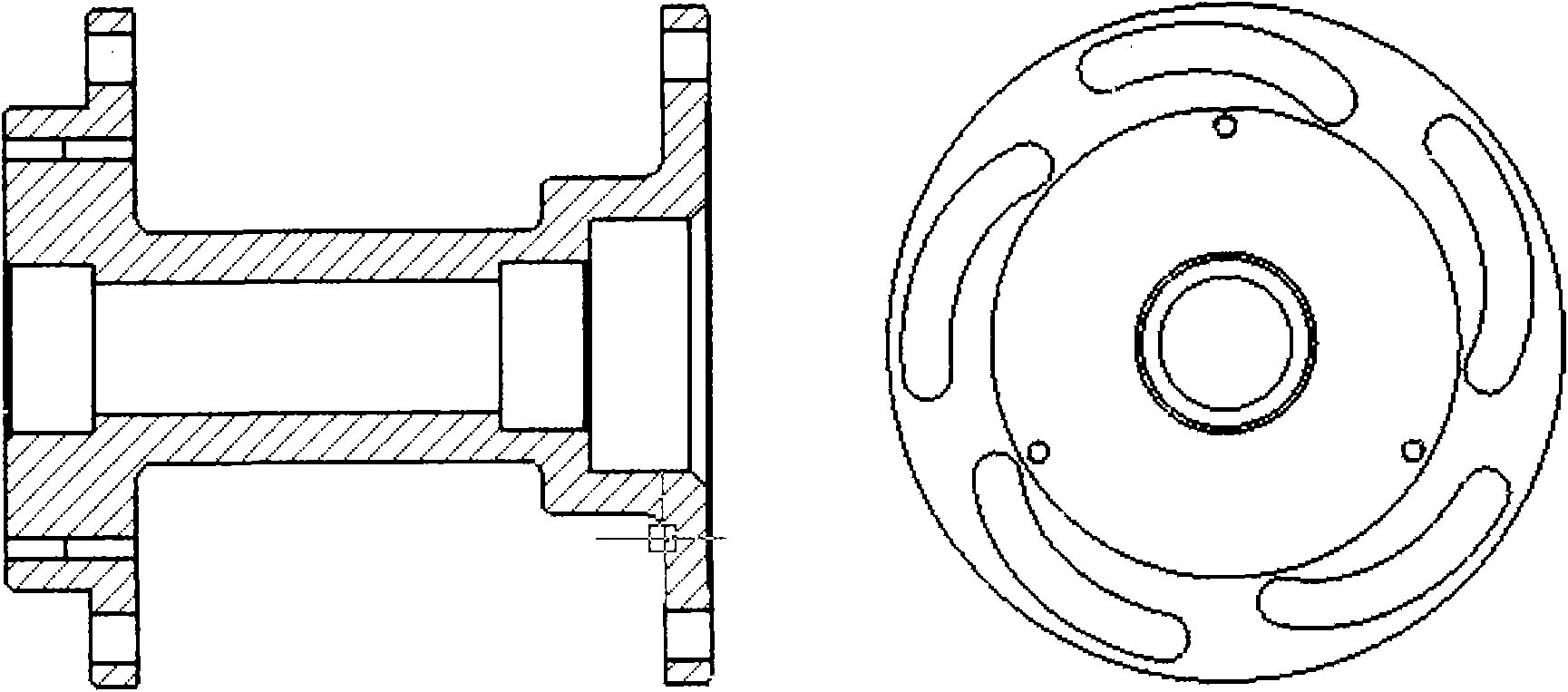

[0014] exist figure 2 In the shown embodiment, the knob (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com