Valve with built-in heater

A heater and piston technology, applied in valve operation/release device, valve device, valve heating/cooling device, etc., can solve problems such as inability to withstand high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

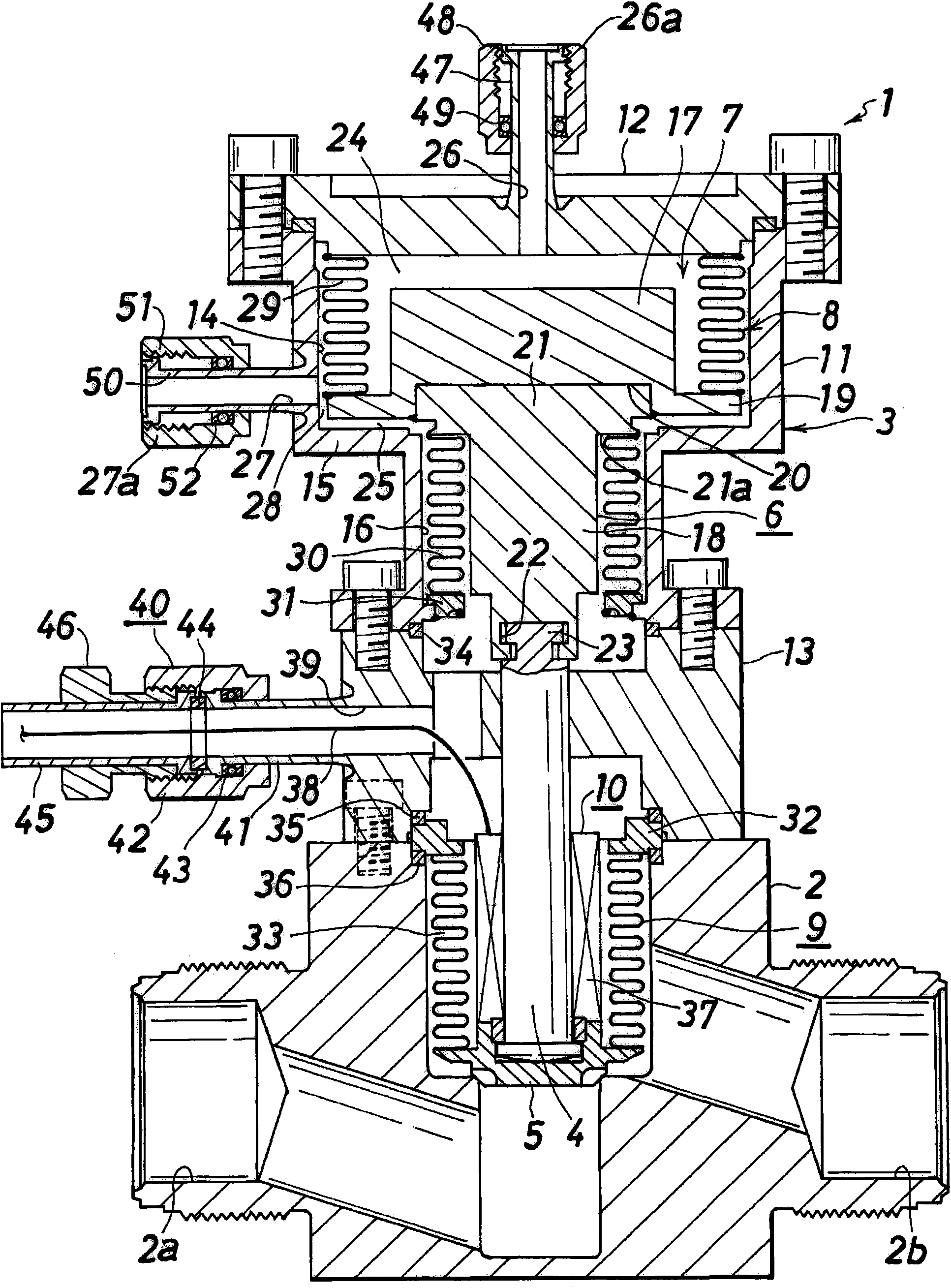

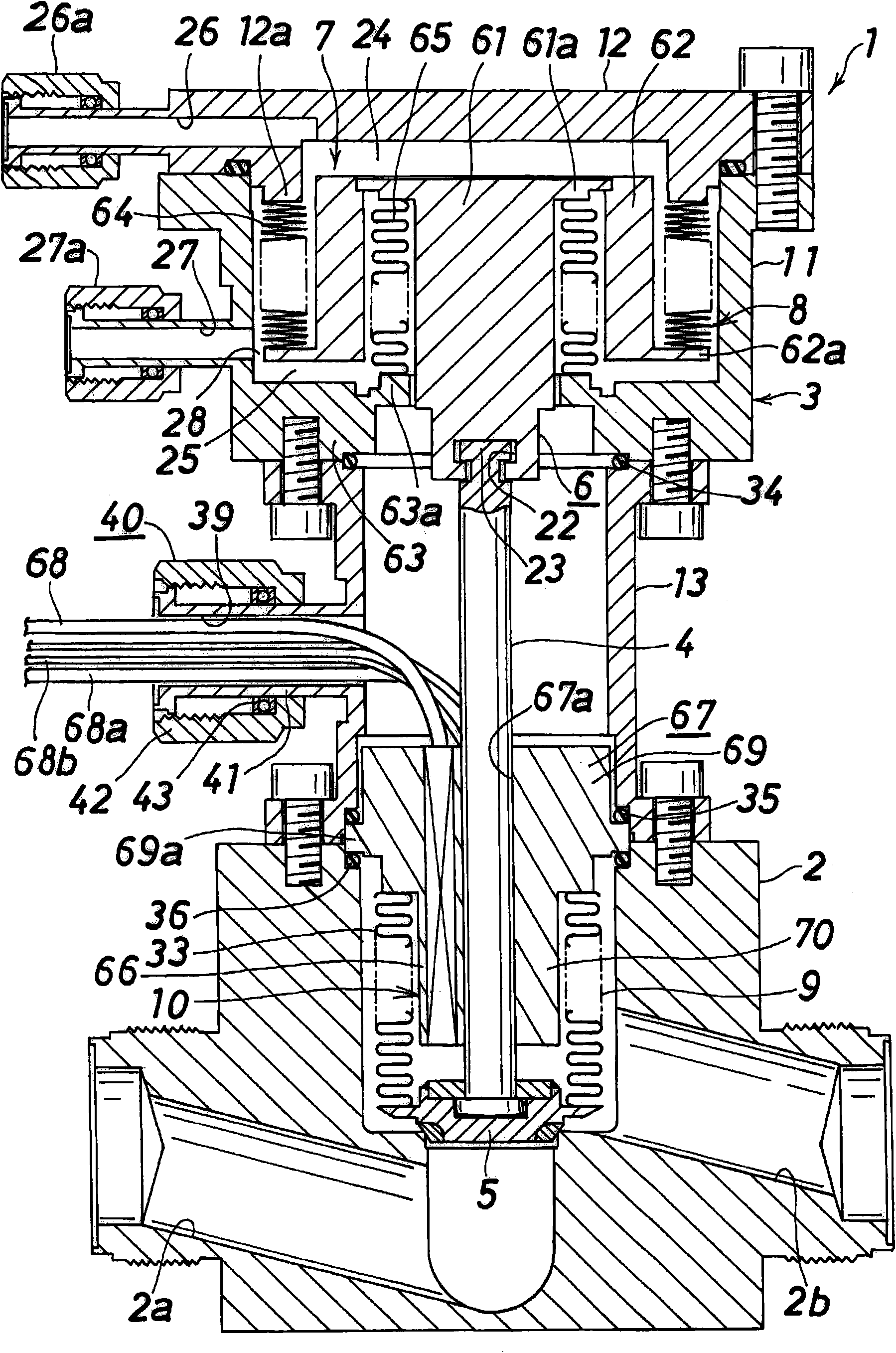

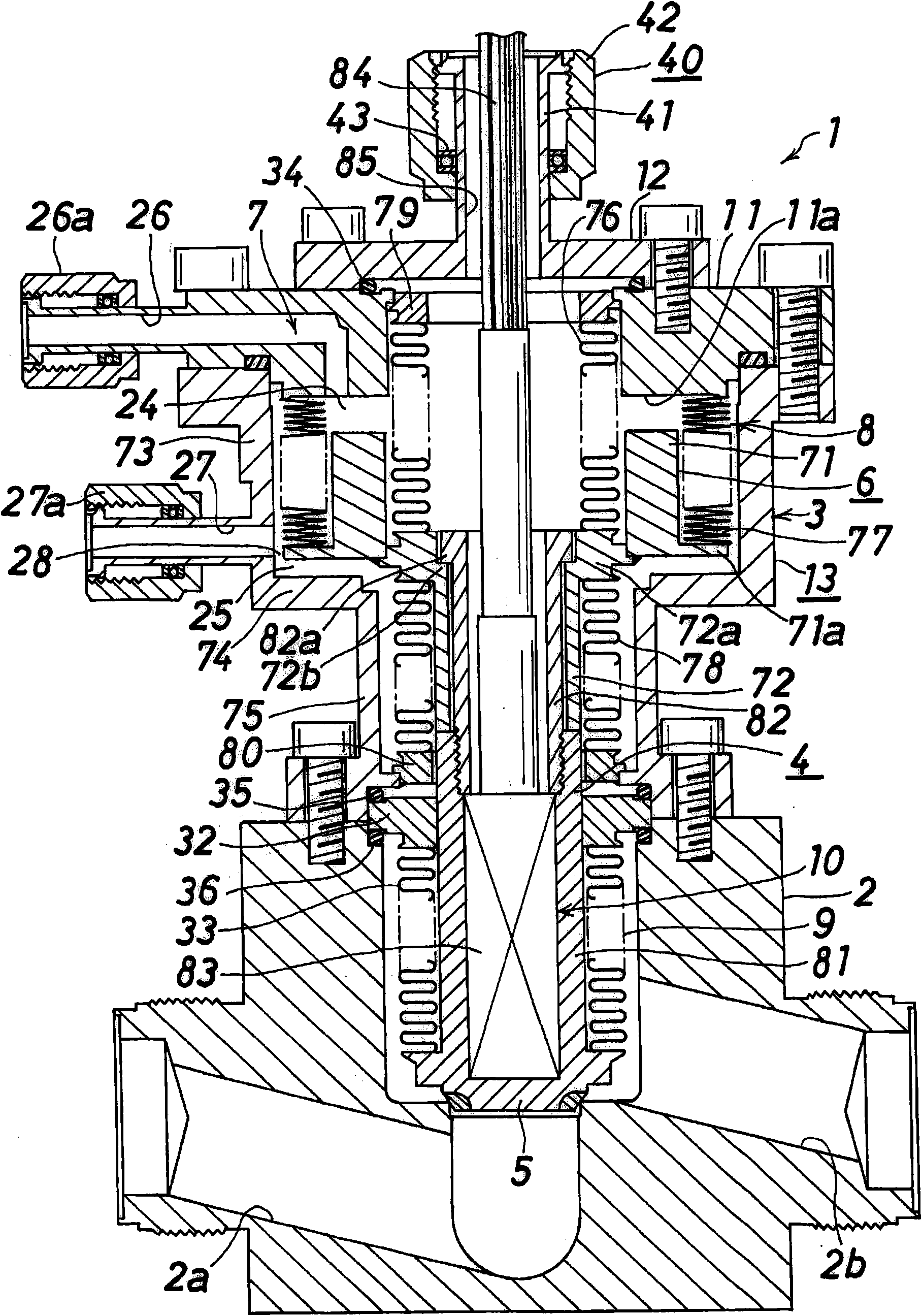

[0073] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following description, up, down, and left and right refer to up, down, and left and right in each figure.

[0074] The first embodiment of the valve 1 with a built-in heater based on the present invention is as follows figure 1 As shown, it has: a valve body 2 provided with a fluid inflow passage 2a and a fluid outflow passage 2b; a housing 3 fixed on the upper end of the valve body 2; the upper part of the valve body 2 is freely movable up and down, and the upper part is in the housing 3 The valve rod 4 inside; the valve core 5 that is suspended and supported on the lower end of the valve rod 4, and the fluid inflow passage 2a is opened and closed along with the up and down movement of the valve rod 4; the piston 6 fixed on the upper end of the valve rod 4; the piston 6 The piston driving mechanism 7 that moves up and down; the piston sealing mechanism 8 that sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com