Cold-strip steel bidirectional deviation correction control system

A control system and technology for cold-rolling strip steel, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems such as mechanical equipment damage and strip edge damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

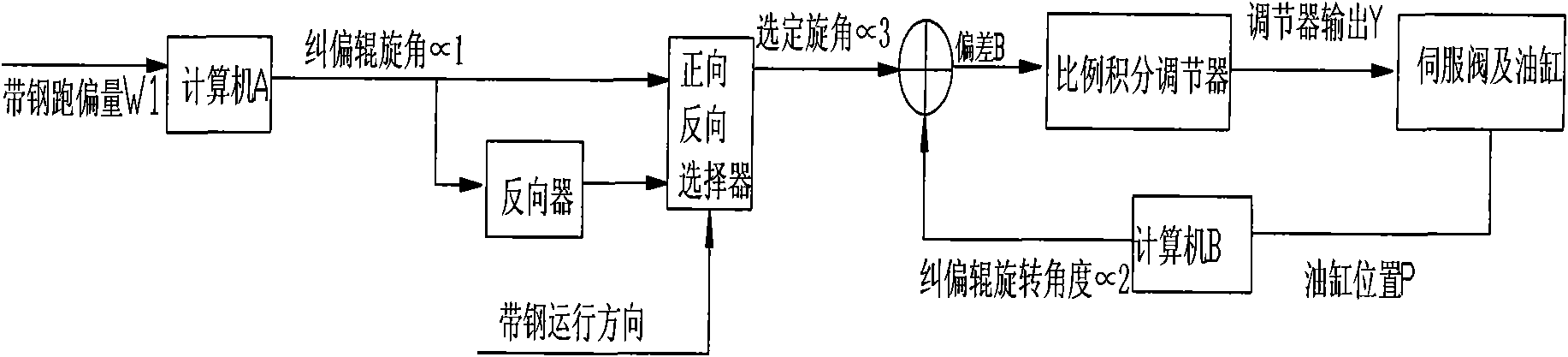

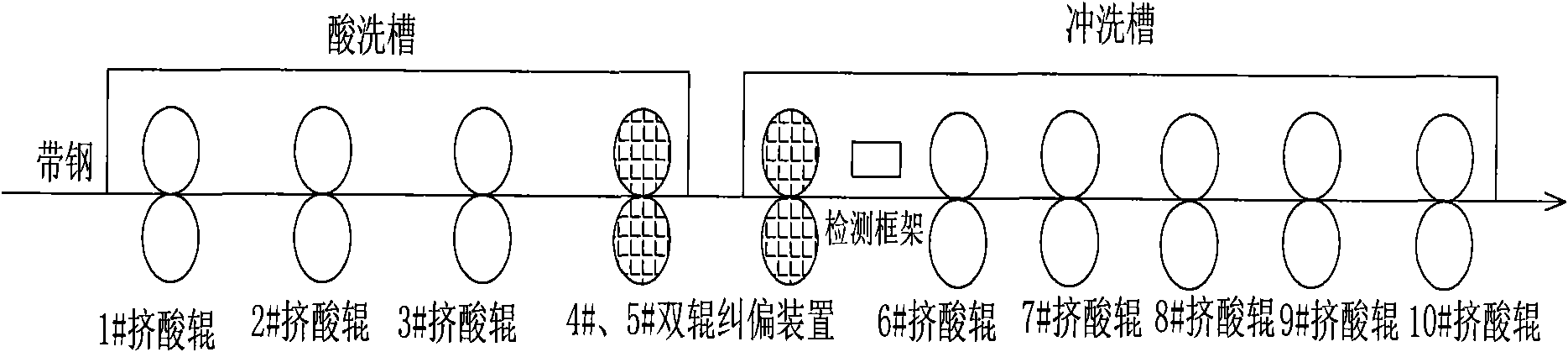

[0025] See figure 1 As shown, the present invention discloses a two-way deviation correction control system for cold-rolled strip steel. The cold-rolled strip correction control system consists of a strip deviation detection device, a correction angle calculator A, a reverser, a forward and reverse selector, an oil cylinder position detection device, an actual correction angle calculator B, a proportional integral Regulators, servo valves and cylinders form a continuous closed-loop system. The deviation of the strip is measured by the detection device of the deviation of the strip, and the value is converted into an electric signal and input into the angle calculator A to be corrected, and the angle to be corrected is calculated. When the strip runs in the forward direction, the forward and reverse selector is selected as forward, and the angle to be corrected is directly input into the forward and reverse selector. When the strip runs in reverse, the forward and reverse sel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap