Nozzle cleaning method, nozzle cleaning device and automatic analysis device

A technology for cleaning devices and nozzles, applied in the direction of injection devices, analytical materials, chemical instruments and methods, etc., can solve the problems of longer dispensing cycle time and inability to achieve high-speed analysis, so as to prevent the cleaning time from becoming longer and be reliable Cleaning, high-speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

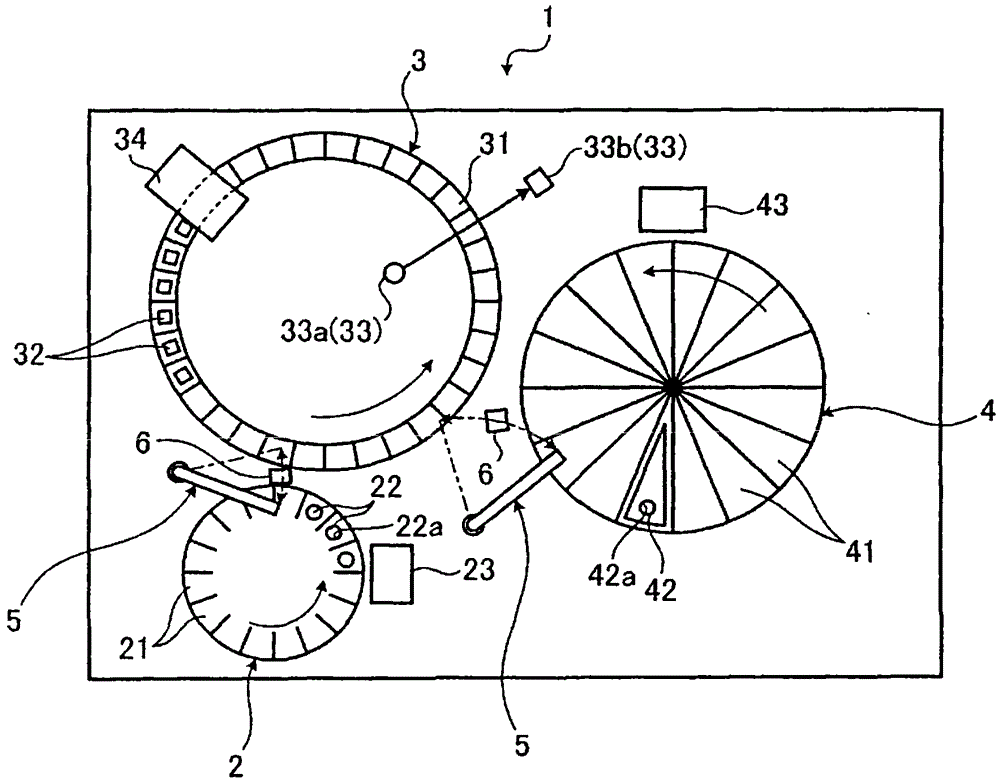

[0073] Hereinafter, preferred embodiments of the nozzle cleaning method, arrangement cleaning device, and automatic analysis device of the present invention will be described in detail with reference to the accompanying drawings. figure 1 It is a schematic configuration diagram showing an automatic analyzer according to an embodiment of the present invention.

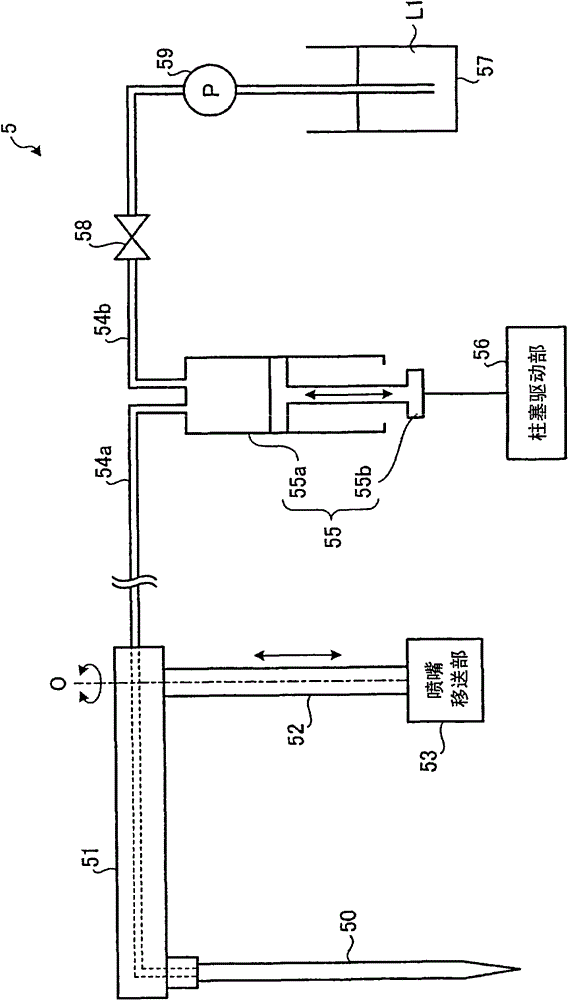

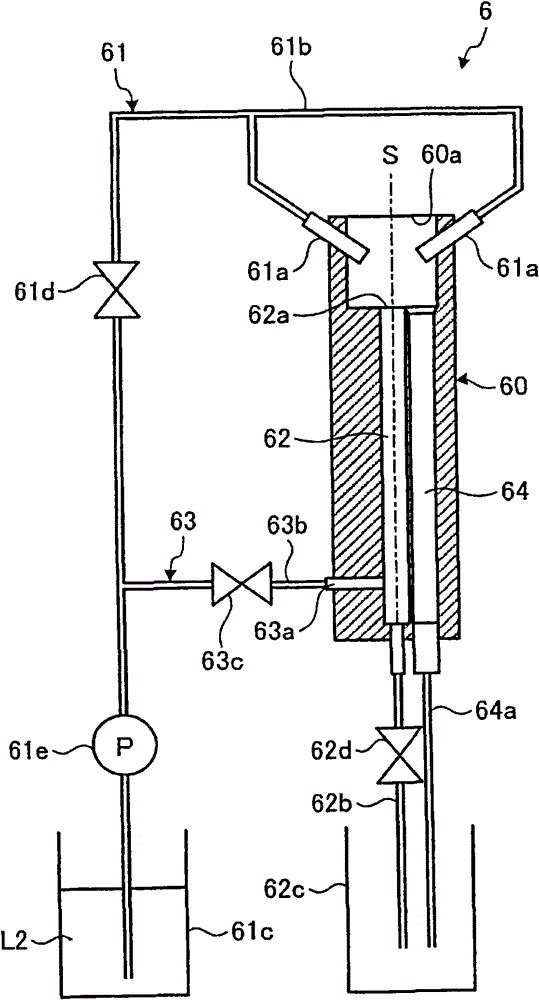

[0074] The automatic analyzer 1 measures the optical characteristics of a reaction solution obtained by mixing a sample (liquid) such as blood or urine with a reagent corresponding to a test item and reacting it, thereby analyzing the component concentration of the sample. The automatic analysis device 1 is provided with a sample loading unit 2, a reaction unit 3, a reagent loading unit 4, a dispensing mechanism (dispensing device) 5, and a nozzle cleaning device 6.

[0075] The sample mounting unit 2 has a disk-shaped table, and includes a plurality of storage portions 21 arranged at equal intervals along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com