Sludge reduction method of urban wastewater treatment process

A treatment process and technology for urban sewage, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unfavorable normal operation of sewage treatment plants, deterioration of effluent quality, and operating costs Low-level problems, to achieve the effect of maintaining the same water quality in sewage treatment, low infrastructure renovation costs, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

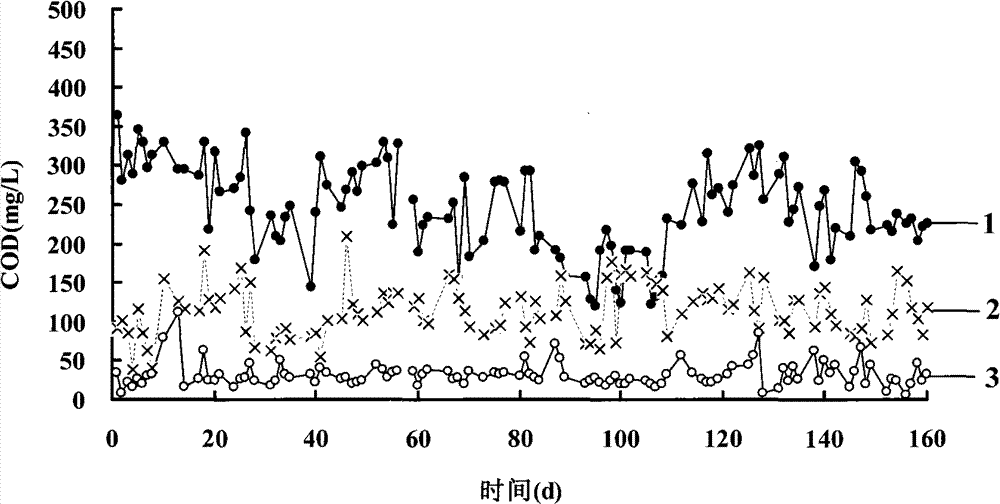

[0041] Example 1 The effect of sludge reduction method on the COD of AB process inlet and outlet water

[0042] In this embodiment, the change of the COD (chemical oxygen demand) value of the AB process inlet and outlet water before and after sludge reduction is studied and analyzed.

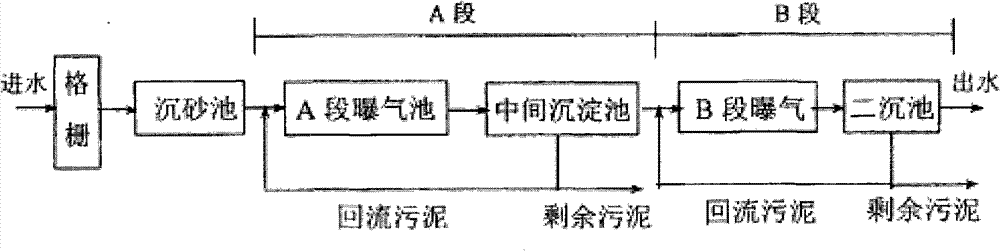

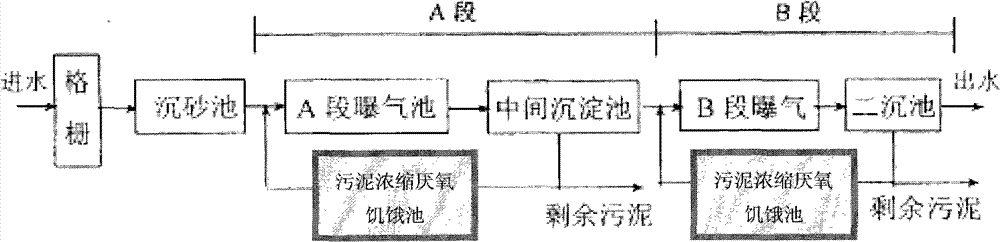

[0043] The influent COD basically keeps fluctuating in the range of 200~400mg / L, and the existing AB process is used for the first 0~60 days (the process is as figure 1 Shown), and then partially modify the existing AB process, according to figure 2 As shown in the process flow chart, the sludge thickening tank of the sludge treatment plant is set into the pipe of the existing AB process. The parameters of the sludge thickening tank are controlled as follows: return sludge retention time: 24h, stirring rate: 120sec / hour, Sludge exchange rate: 50% (mass), 60 to 160 days of sewage treatment testing, the results are as follows image 3 Shown.

[0044] The biggest feature of AB process is that after A-sta...

Embodiment 2

[0046] Example 2 Sludge reduction method for AB process influent NH 4 -N value influence

[0047] In this example, before and after sludge reduction, AB process inlet and outlet NH 4 -N value changes over time for research and analysis.

[0048] The existing AB process (the process is as figure 1 Shown), and then partially modify the existing AB process, according to figure 2 As shown in the process flow chart, the sludge thickening tank of the sludge treatment plant is set into the pipe of the existing AB process. The parameters of the sludge thickening tank are controlled as follows: return sludge retention time: 24h, stirring rate: 120sec / hour, Sludge exchange rate: 50% (mass), 60 to 160 days of sewage treatment testing, the results are as follows Figure 4 Shown.

[0049] Due to the short residence time of the sewage in the A-level, the ammonia nitrogen has not been degraded, and part of the organic nitrogen in the total nitrogen in the influent is converted into ammonia nitroge...

Embodiment 3

[0052] Example 3 The effect of sludge reduction method on the SS value of AB process inlet and outlet water

[0053] In this embodiment, the change of the SS (suspended matter) value of the AB process before and after the sludge reduction is studied and analyzed.

[0054] The existing AB process (the process is as figure 1 Shown), and then partially modify the existing AB process, according to figure 2 As shown in the process flow chart, the sludge thickening tank of the sludge treatment plant is set into the pipe of the existing AB process. The parameters of the sludge thickening tank are controlled as follows: return sludge retention time: 24h, stirring rate: 120sec / hour, Sludge exchange rate: 50% (mass), 60 to 160 days of sewage treatment testing, the results are as follows Figure 5 Shown.

[0055] The influent SS fluctuates greatly, but it is relatively stable after A-level treatment, basically stable at 70mg / L. After the AB two-stage effluent, the average SS of the effluent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com