Method for separating a semiconductor wafer into individual semiconductor dies using an implanted impurity

A technology of semiconductor tubes and semiconductors, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

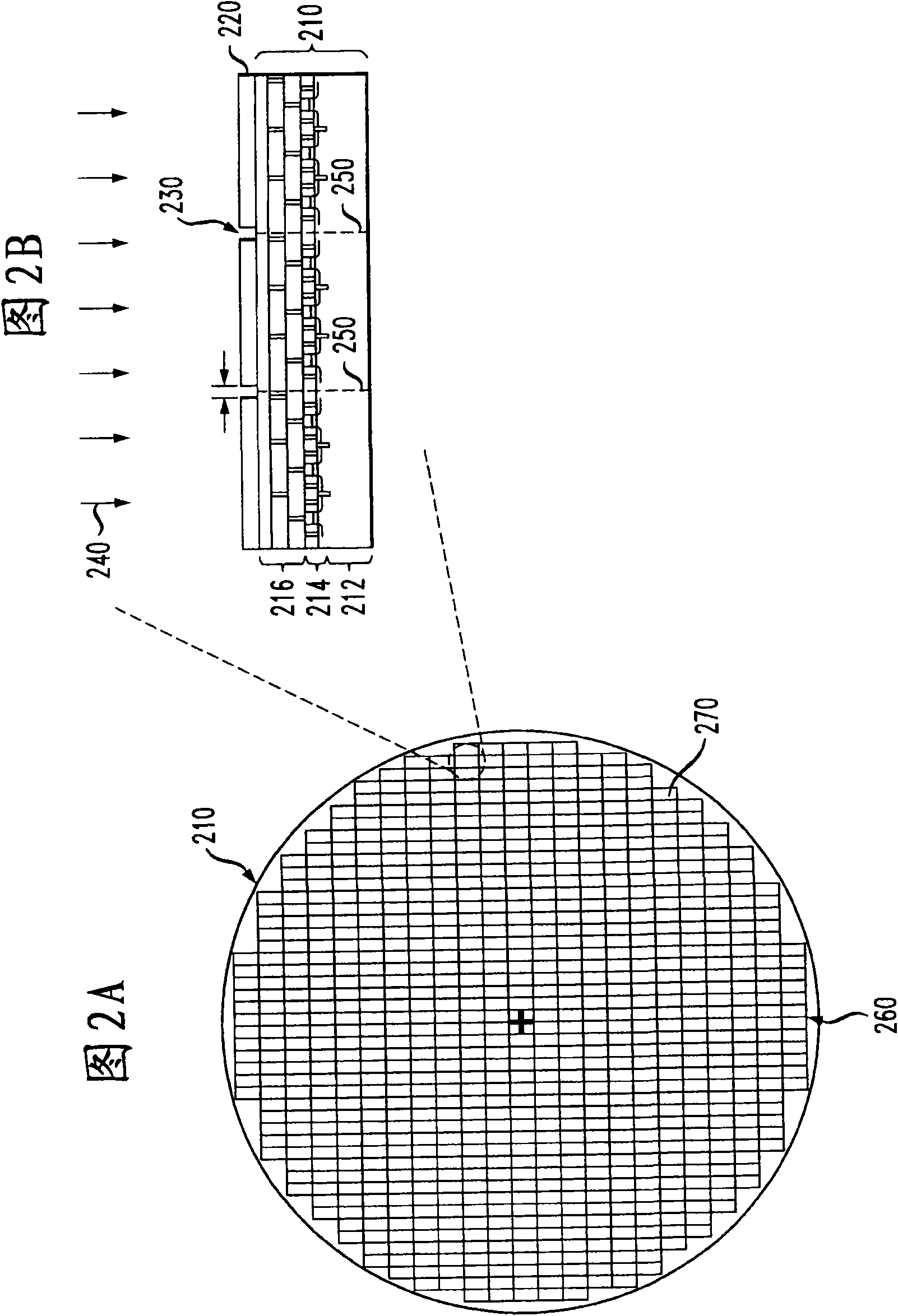

[0010] The present disclosure is based at least in part on the recognition that impurities may be implanted into a semiconductor wafer adjacent to connection locations where semiconductor die are interconnected to facilitate separation of the semiconductor wafer into individual semiconductor dies. The present disclosure also recognizes that implanted impurities can break bonds in the semiconductor wafer adjacent to the connection locations, creating regions of weakness along which the semiconductor wafer can be separated into individual semiconductor dies.

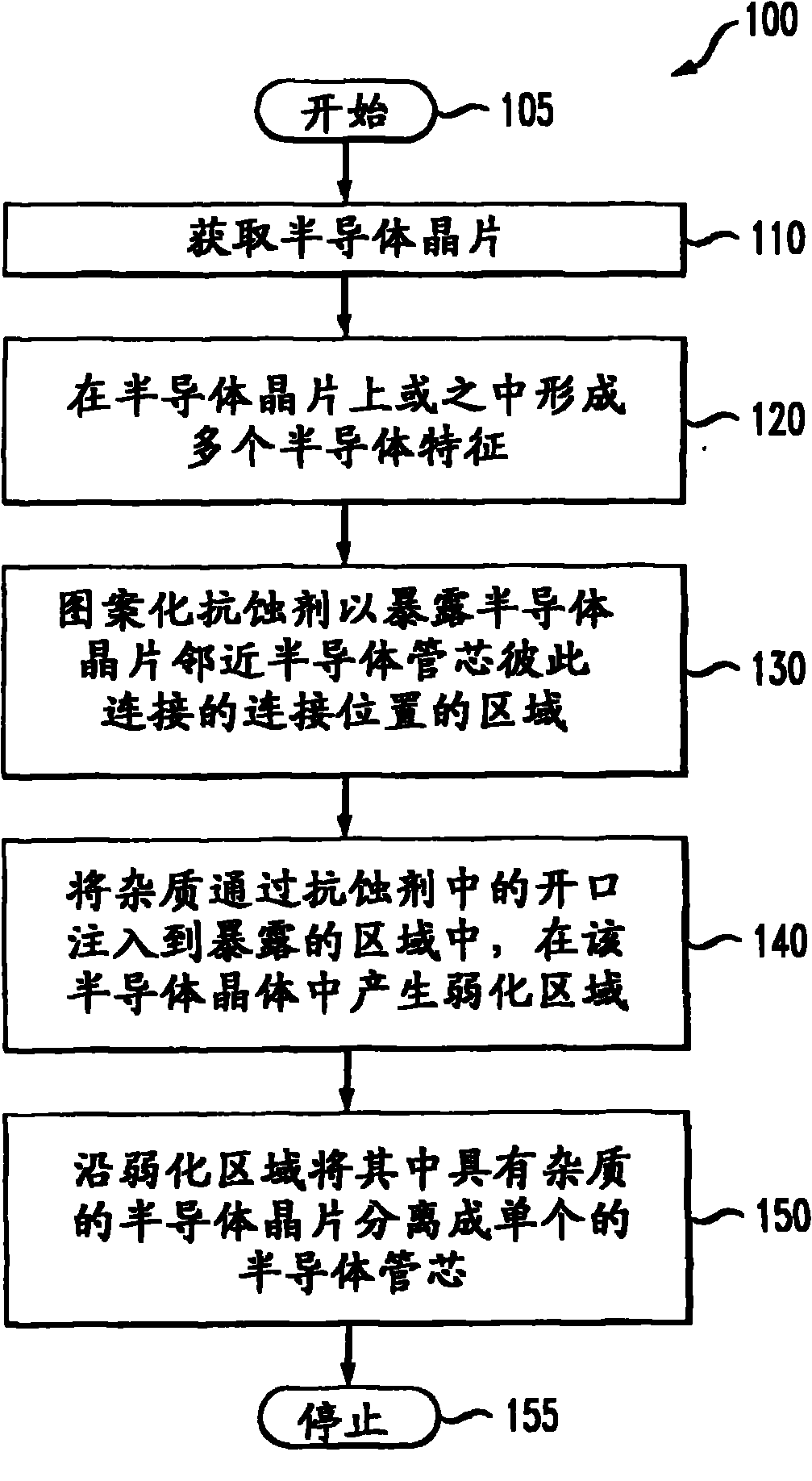

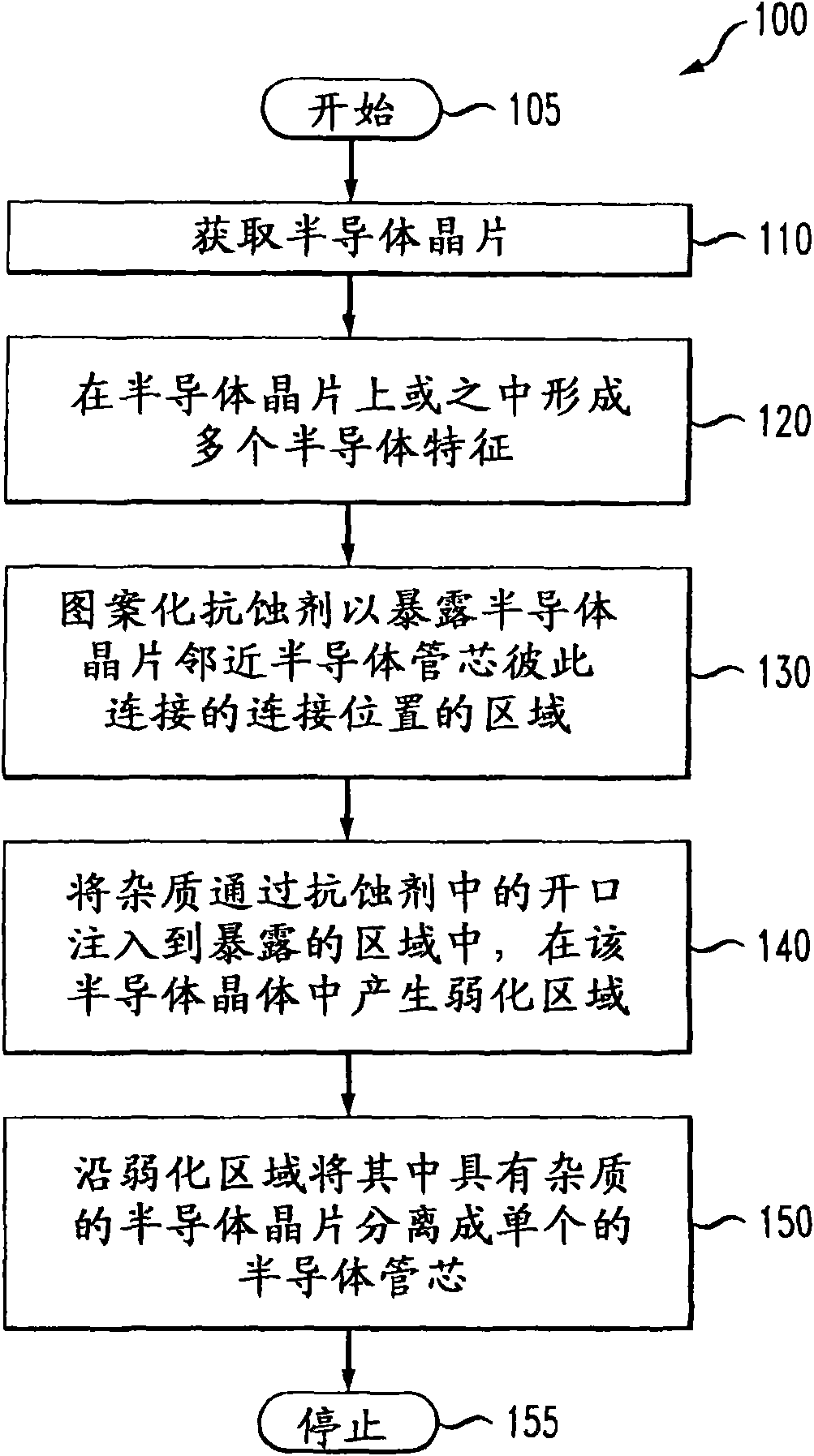

[0011] FIG. 1 shows a flowchart 100 representing an embodiment of a method for fabricating a semiconductor die. In addition to methods for fabricating semiconductor dies, the flowchart includes a subset of methods for separating a semiconductor wafer into individual semiconductor dies. Accordingly, flowchart 100 should not be used to limit the disclosure to any particular steps.

[0012] Flowchart 100 begins with start st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap