Anti-twist opening cover die device for compressed stranded steel wire rope

A technology for steel wire ropes and compacted strands, which is applied in the field of die sets for compacted strand steel wire ropes, achieving the effects of simple structure, high production efficiency, and accurate and stable geometric positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

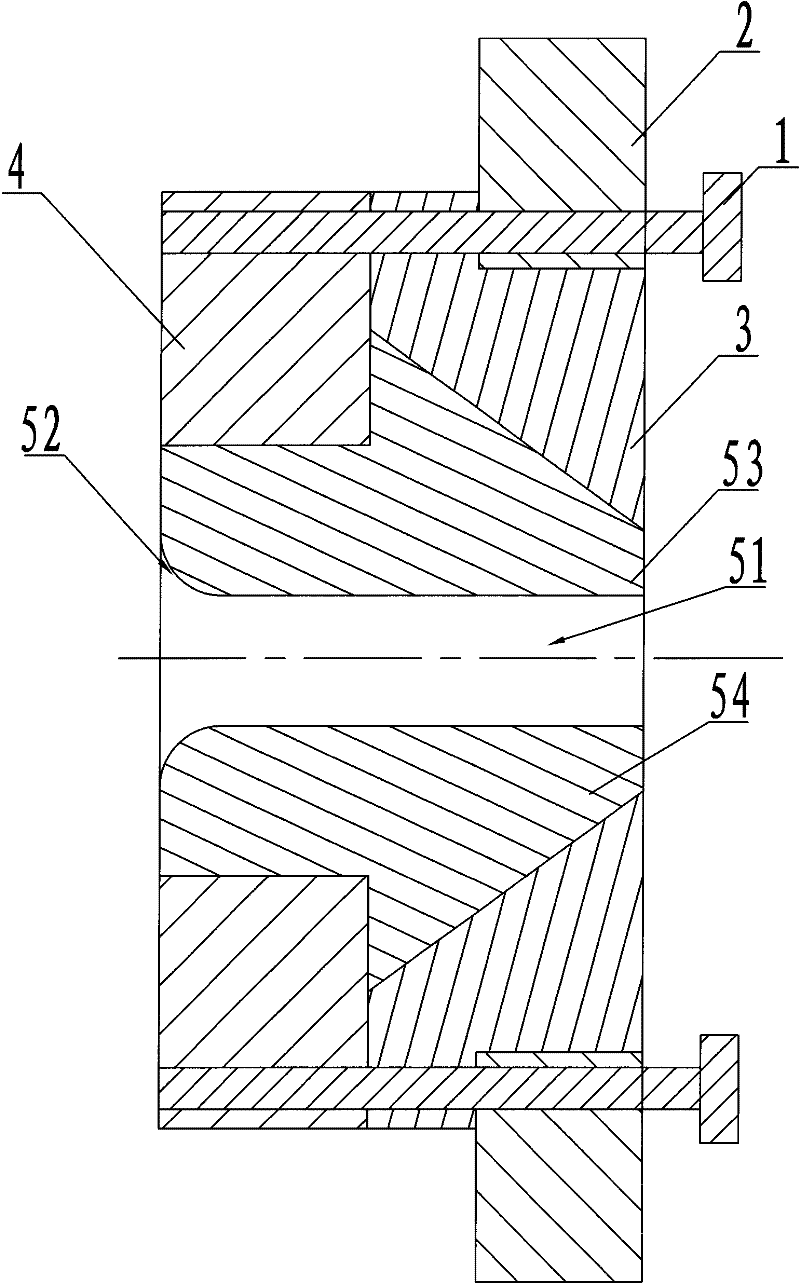

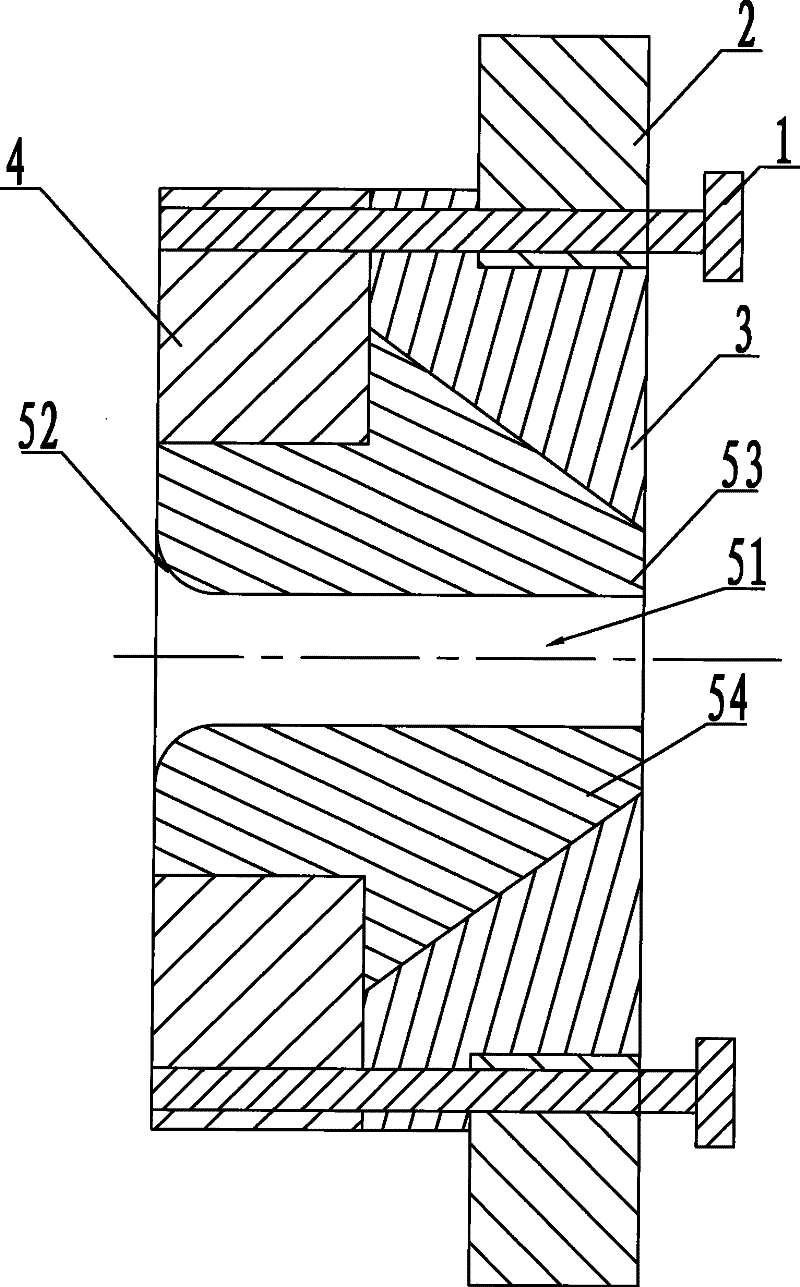

[0007] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0008] like figure 1 As shown, the anti-twist open mold device for compacting strand steel wire rope includes: positioning plate 2, positioning sleeve 3 and cover plate 4 fixed together by positioning screw 1, and the positioning sleeve 3 and cover plate 4 communicate with each other respectively The positioning sleeve installation cavity and the cover plate installation cavity are provided with an anti-twist opening sleeve mold cooperating with the positioning sleeve installation cavity and the cover plate installation cavity, and a through hole 51 is arranged in the anti-twist opening sleeve mold , one end of the anti-twist opening sleeve is provided with a trumpet-shaped opening 52 communicating with the through hole 51. The anti-twist opening sleeve is composed of an upper half-mold 53 and a lower half-mold 54 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com