Drive mechanism for medium voltage fuse switch and corresponding medium voltage fuse switch

A technology of driving mechanism and fuse switch, which is applied in the direction of power device, electric switch, contact operating mechanism, etc. inside the switch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

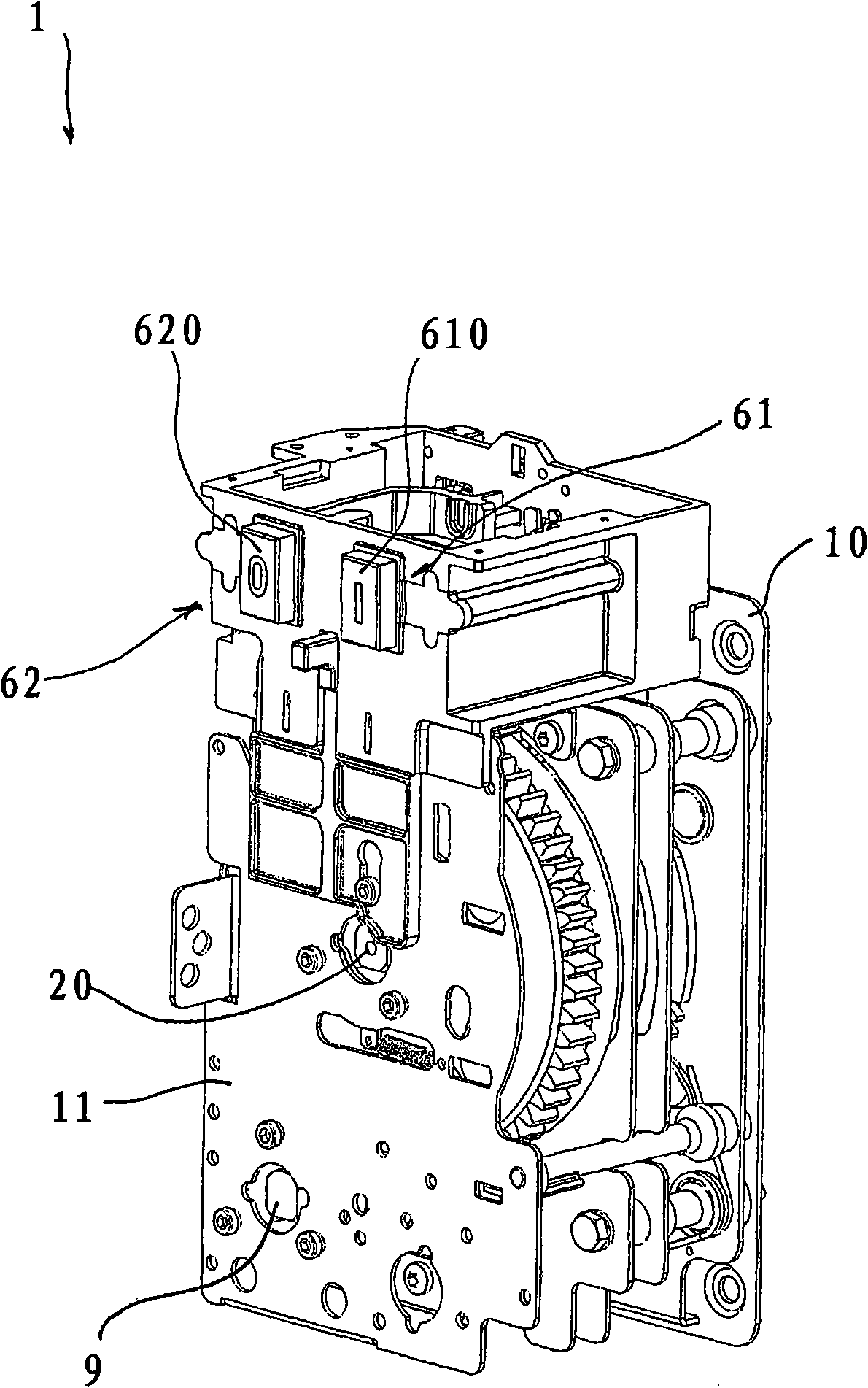

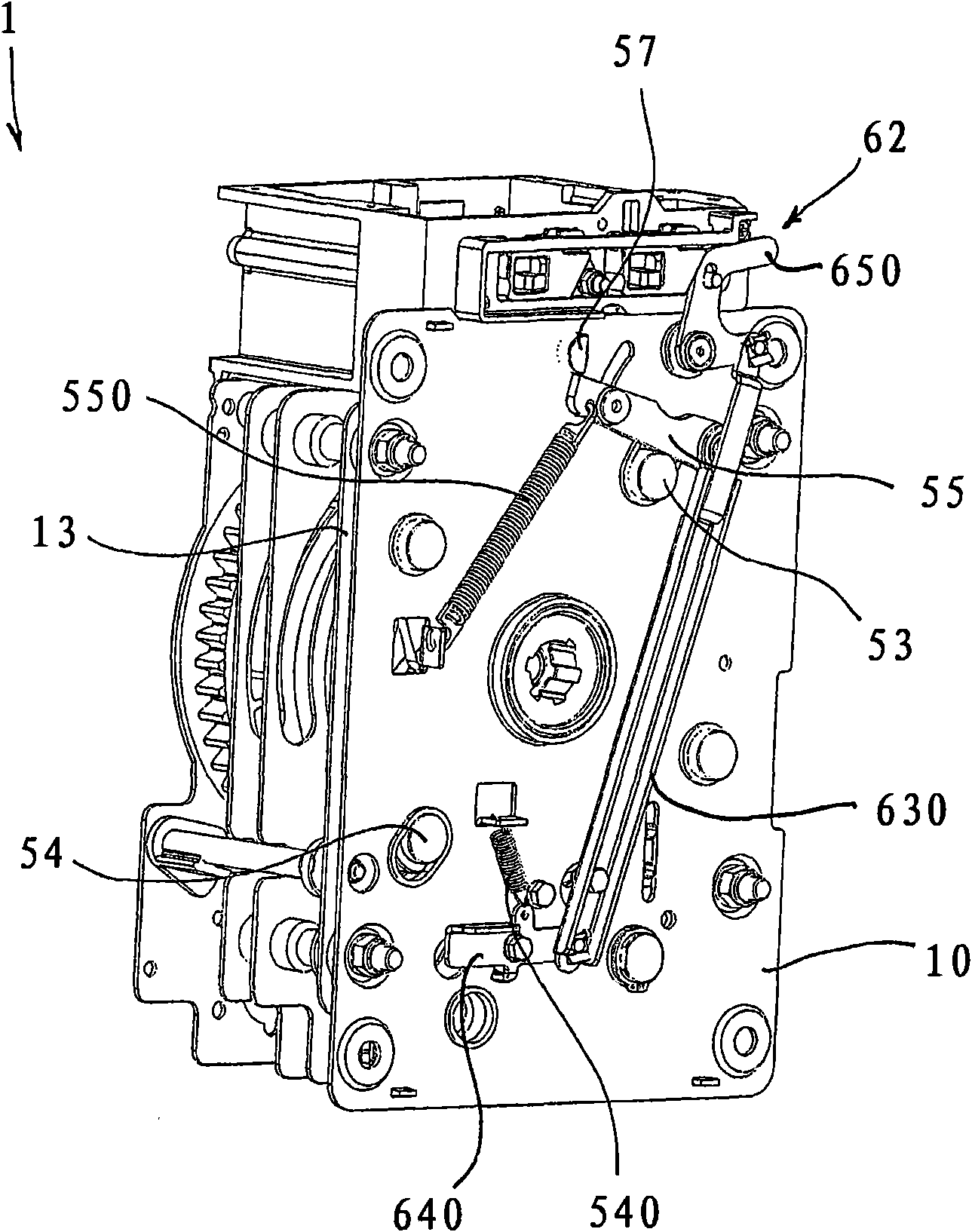

[0028] Referring to the accompanying drawings, a driving mechanism for a medium voltage fuse switch according to the present invention, generally indicated by reference numeral 1, generally includes a base plate 10 and a front plate 11 defining an inner space. There may also be additional plates, such as plate 13 , between the base plate 10 and the front plate 11 . The drive mechanism also includes several components (which may be of conventional type and will not be described in detail) for connecting it to a medium voltage switch.

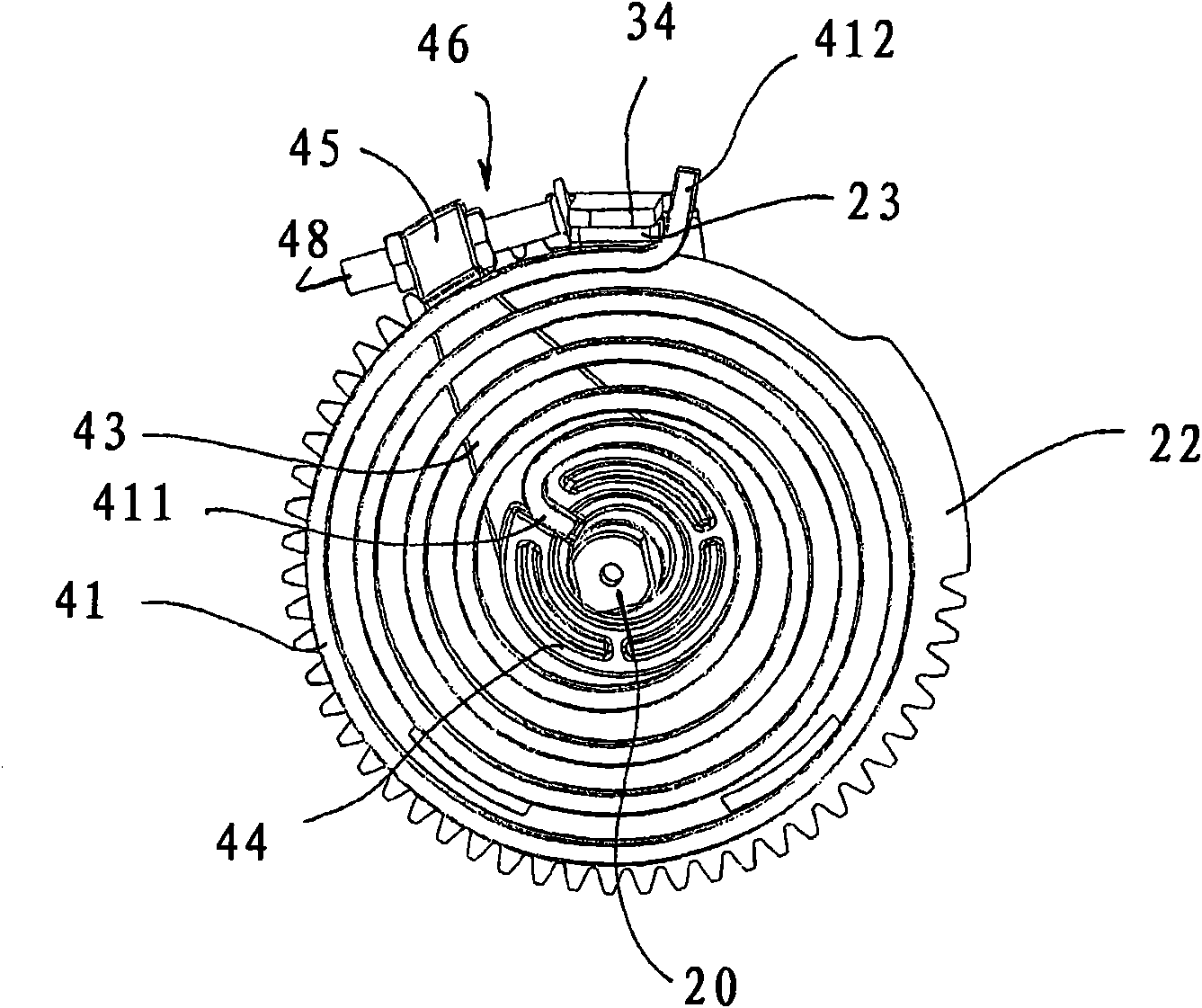

[0029] an operating shaft 2 and a power shaft 3 are accommodated in said interior space and are mounted coaxially along a first longitudinal axis, said power shaft 3 being operatively connectable to the kinematic chain of a medium voltage fuse switch by conventional connection systems, to actuate the open / close operation of the switch. The operating shaft 2 has a head 20 connectable through a hole provided on the front plate 11 of the drive mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com