Hard aluminum forming mechanism of flat plate type blister packaging machine

A technology of a blister packaging machine and a forming mechanism, which is applied to packaging and other directions, can solve the problems of poor quality of blister stretching, wrinkling around the blister, loosening of aluminum foil, etc., achieves outstanding substantive features, and solves easy loosening. , The effect of convenient mold change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

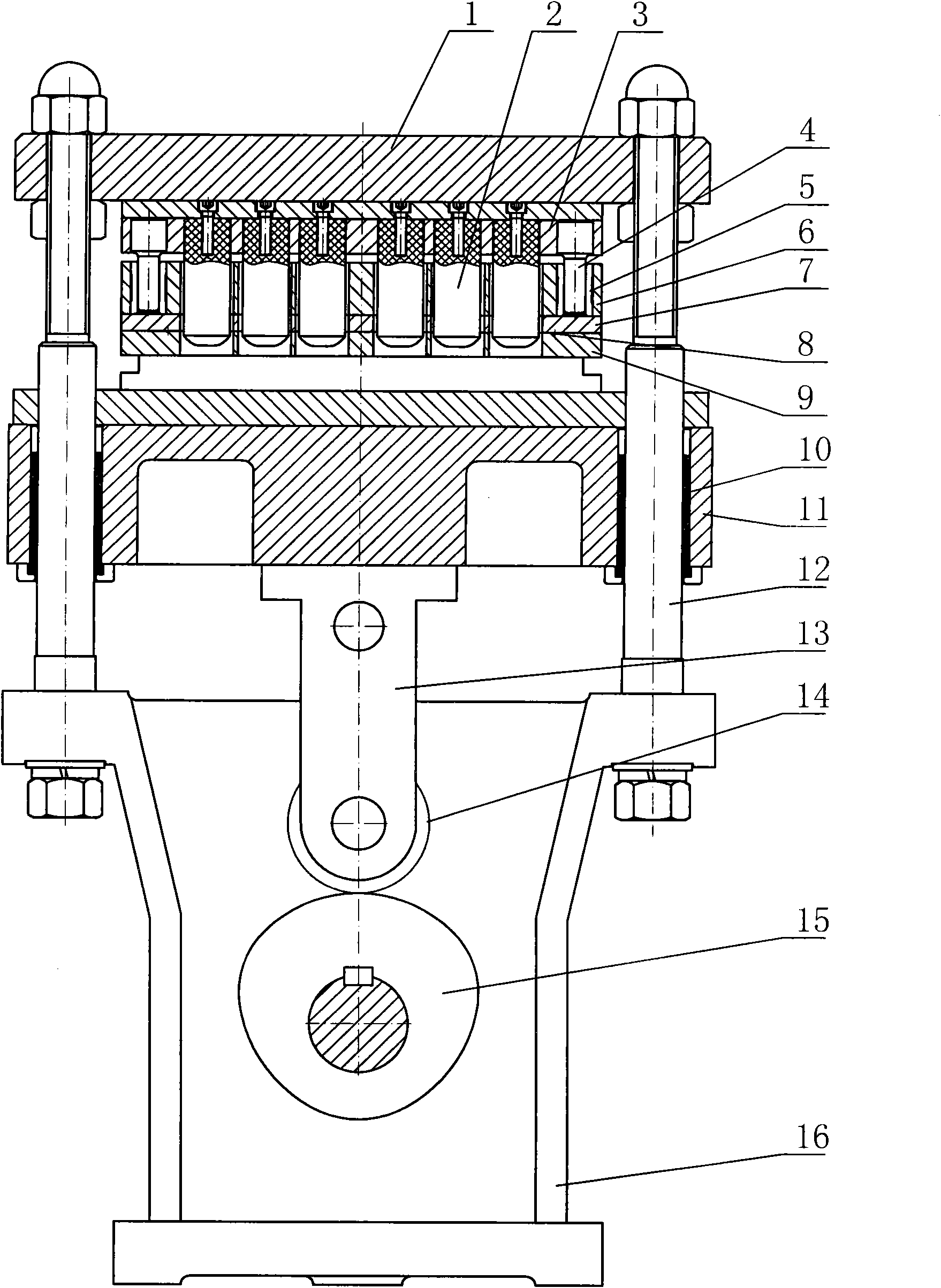

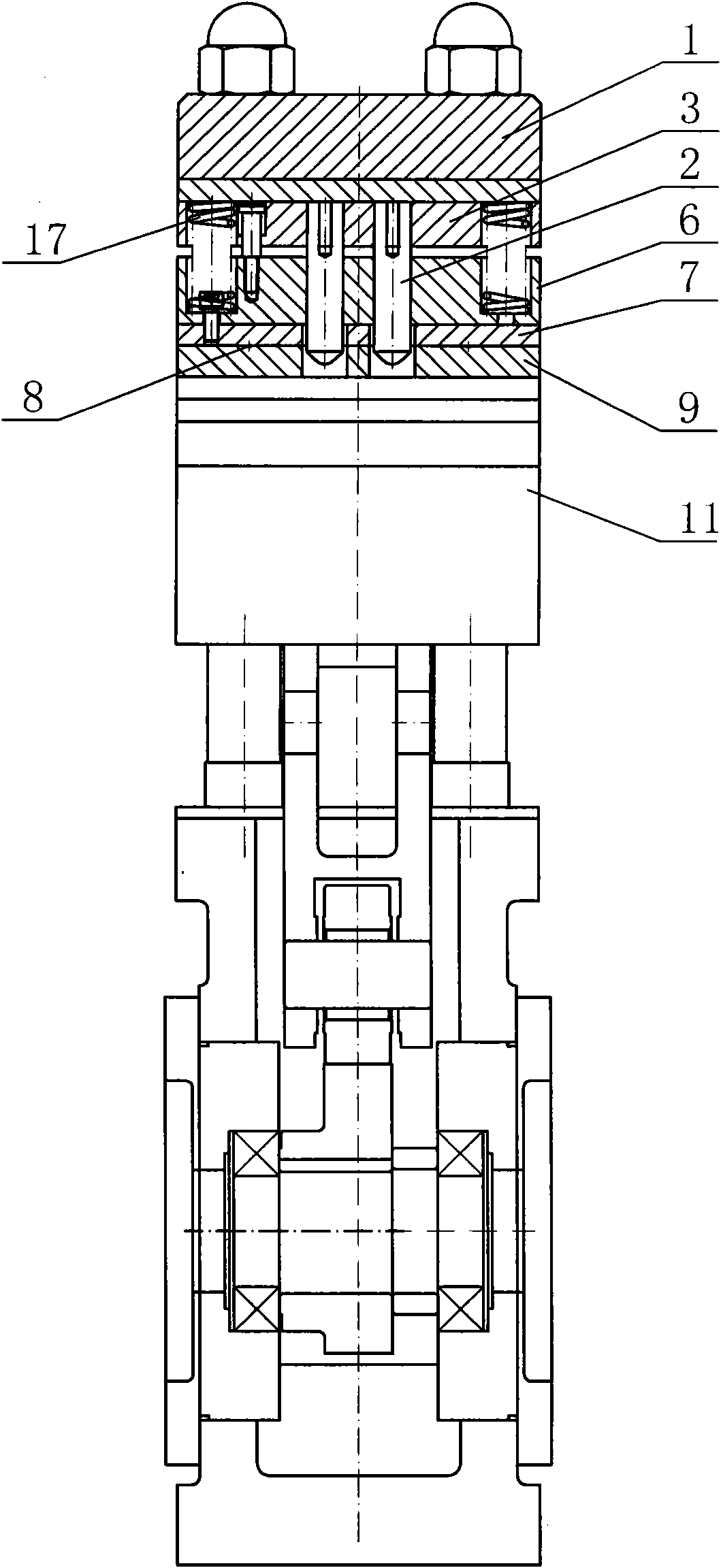

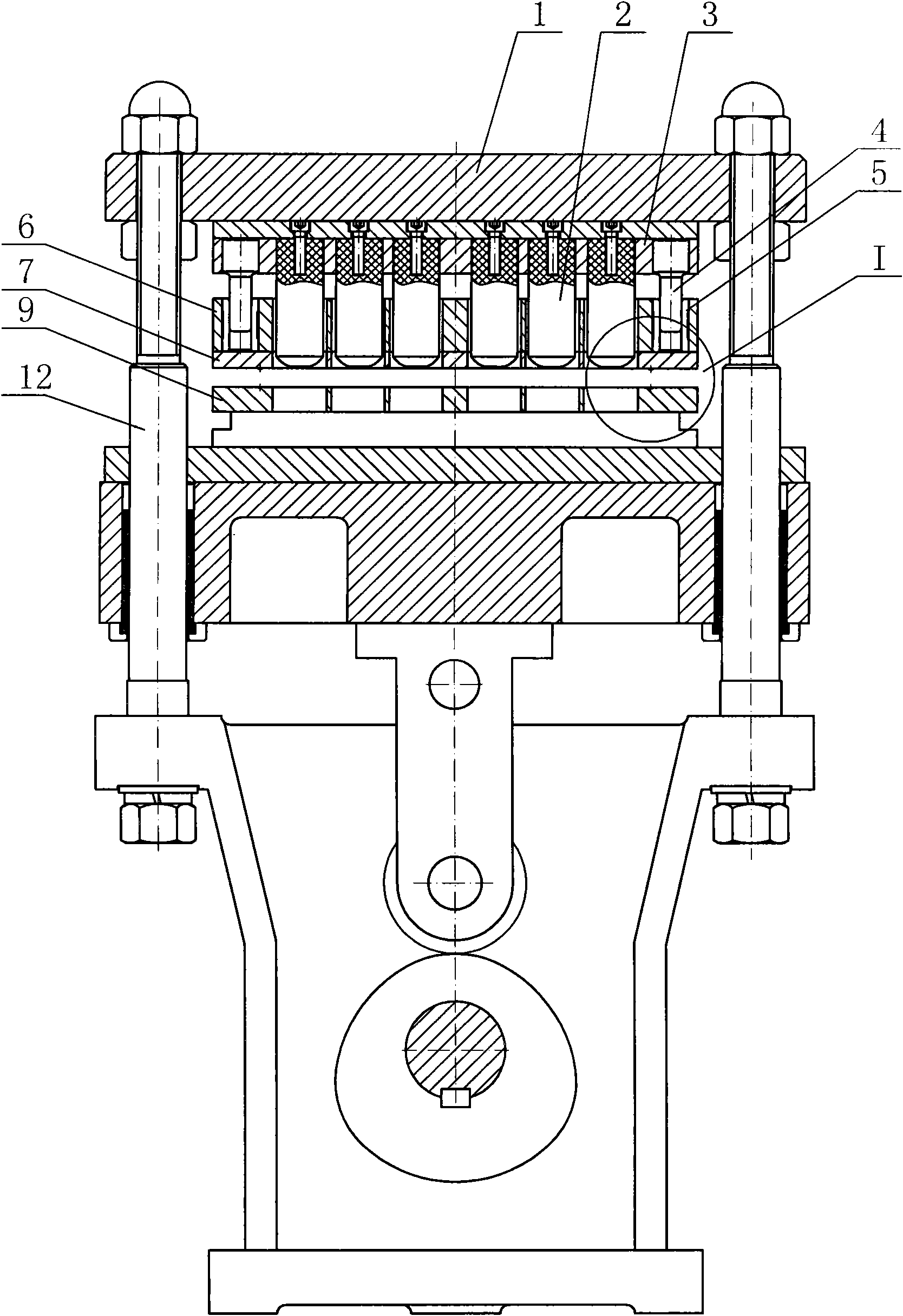

[0013] Refer to attached figure 1 , 2 , 3, 4, the hard aluminum forming mechanism of the flat-type blister packaging machine, including the upper mold base 1 and the lower mold base 11, the upper mold base 1 is fixed on the bracket 16 of the packaging machine through the column 12, and the lower mold base 11 passes through The steel ball sleeve 10 is slidably arranged on the column 12, and the bottom surface of the lower mold base 11 is fixed with a roller seat 13, and the roller 14 provided on the roller seat 13 leans against the curved surface of the cam 15 of the cam mechanism of the packaging machine, and the cam 15 can be rotated to push down. The die base 11 moves up and down, the lower die base 11 is fixedly equipped with a forming die 9, the upper die base 1 is equipped with a forming punch assembly, and the forming punch assembly includes a forming punch 2 (punch), a fixed punch The plate 3 and the binder plate 7, the forming punch 2 is fixedly connected with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com