Rattle-free structure of mated parts

一种配合结构、部件的技术,应用在带有齿的元件、传动装置零件、卷扬装置等方向,能够解决效率降低等问题,达到提高效率、好响应特性、节省成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

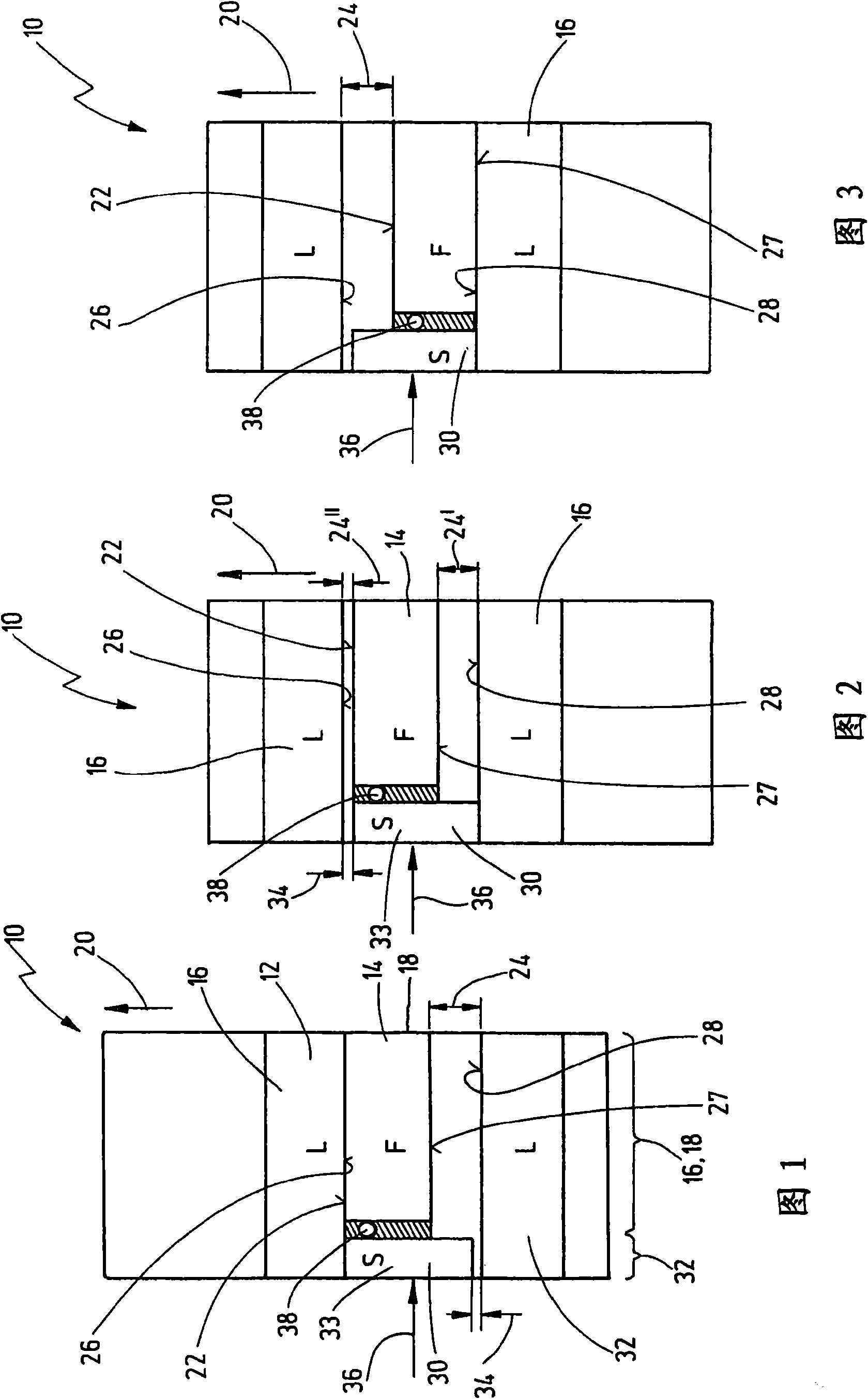

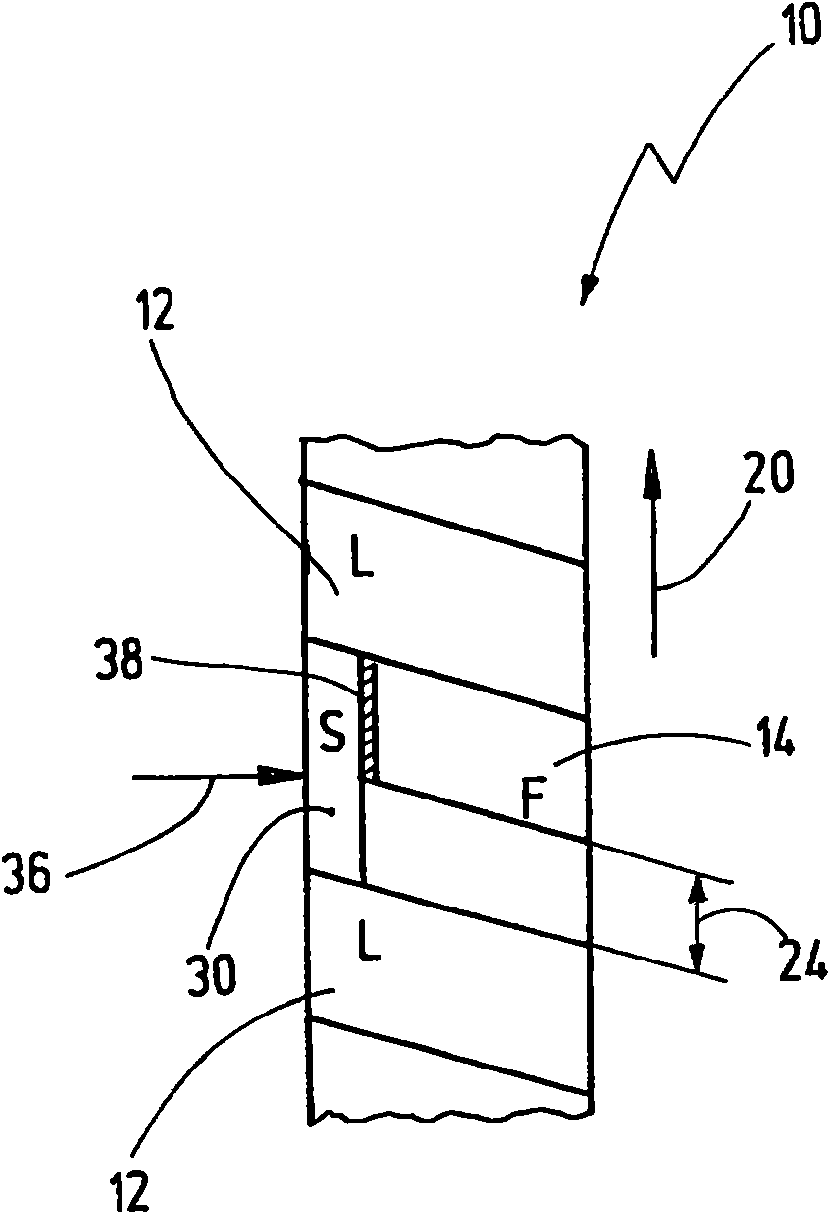

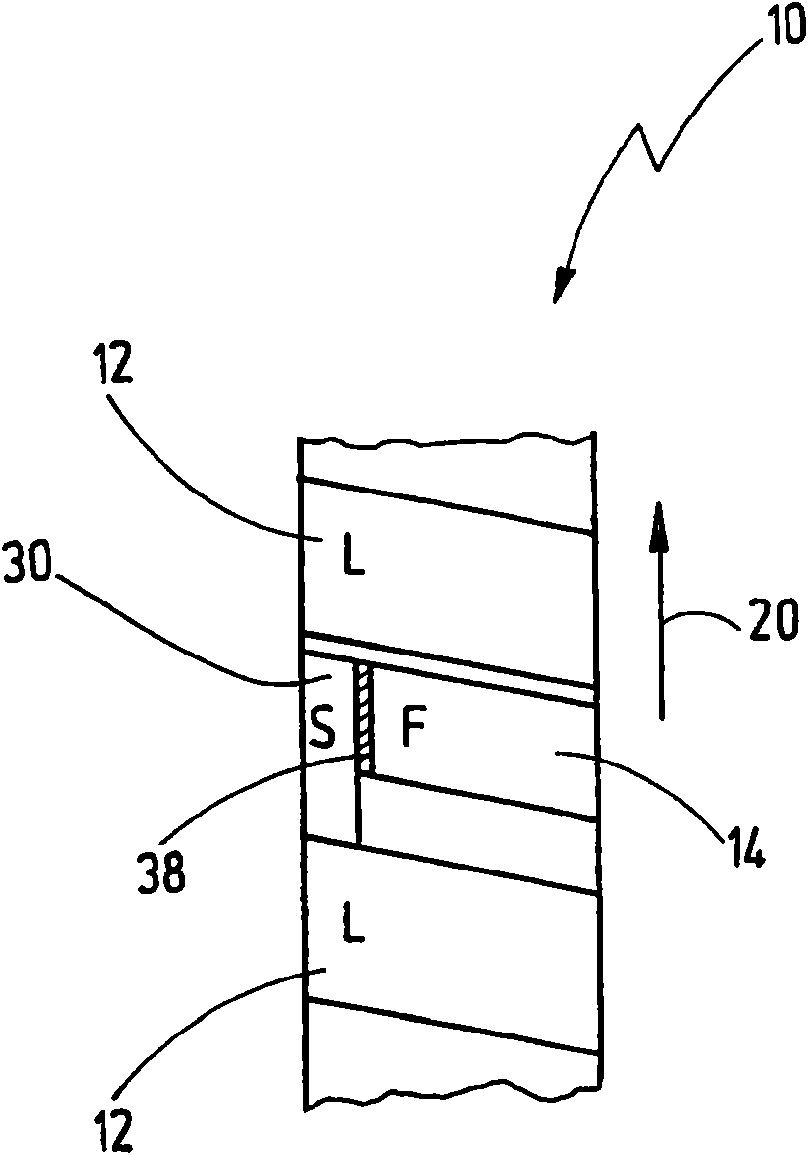

[0233] exist Figures 1 to 3 A first embodiment of the mechanical component engagement according to the invention is shown in FIG. 1 and is generally designated 10 .

[0234] The part cooperation 10 has a first part 12 in the form of a free wheel and a second part 14 in the form of a fixed wheel. The fixed wheel 14 is the active part in the shown case. The free wheel 12 has a first part toothing 16 . The fixed wheel 14 has a second part toothing 18 .

[0235] Freewheel 12 is driven in drive direction 20 by means of fixed pulley 14 . Here, the reverse tooth flank 22 of the second tooth section 18 is connected to the rear tooth flank 26 of the first tooth section 16 .

[0236] The toothing 16, 18 is designed with a certain backlash between figure 1 Expressed in 24.

[0237] The backlash 24 is the distance between the rear flank 28 of the second toothing 18 and the reverse flank 28 of the first toothing 16 in the illustrated case.

[0238] Such toothings are generally know...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com