Partition-free bipolar electrostatic particle coagulator

A technology of agglomerators and no partitions, used in external electrostatic separators, electrostatic effect separation, dispersed particle separation, etc., can solve the problem of low dust removal efficiency of dust collectors, achieve good agglomeration effect, reduce equipment weight, and solve agglomeration efficiency. too low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

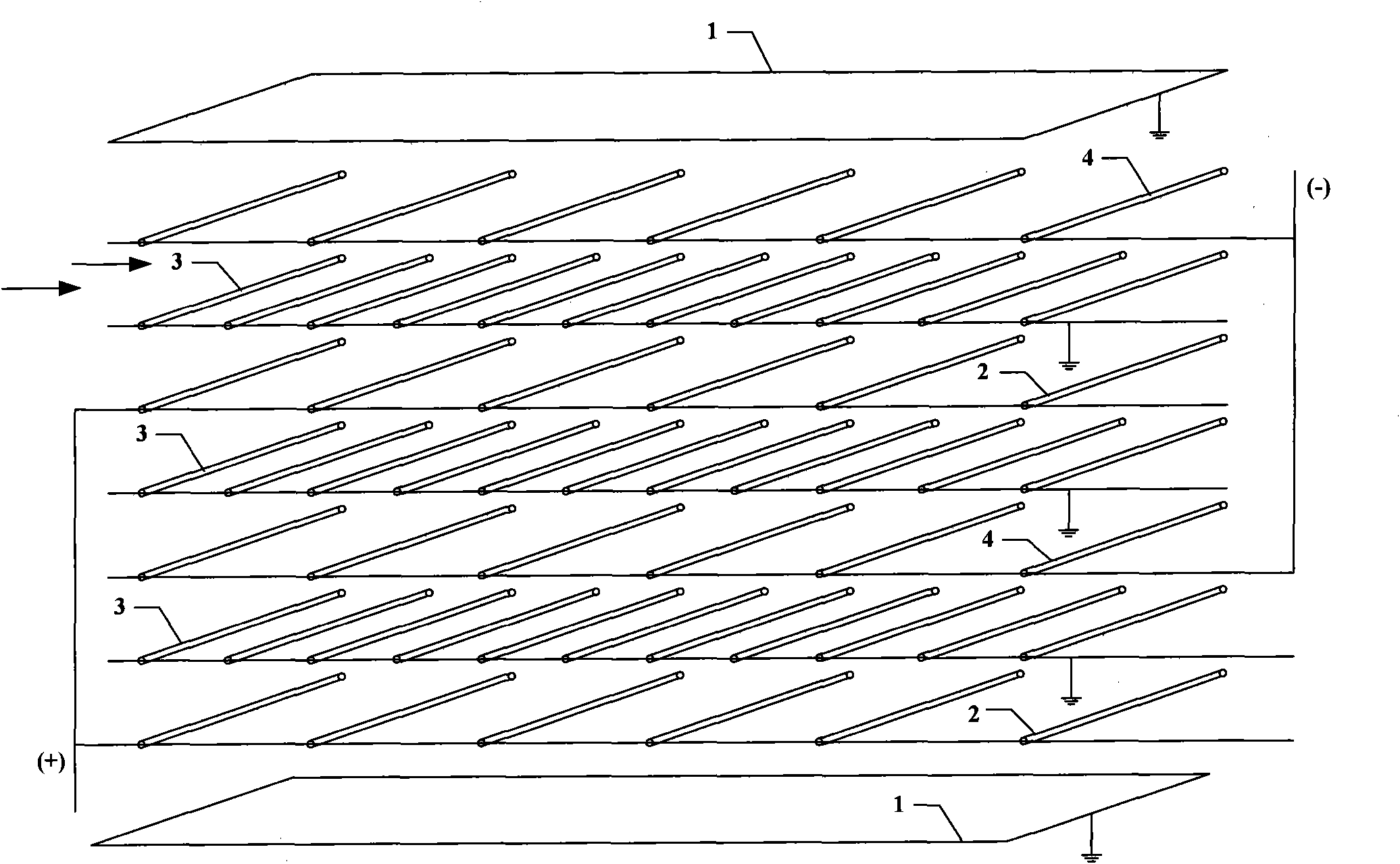

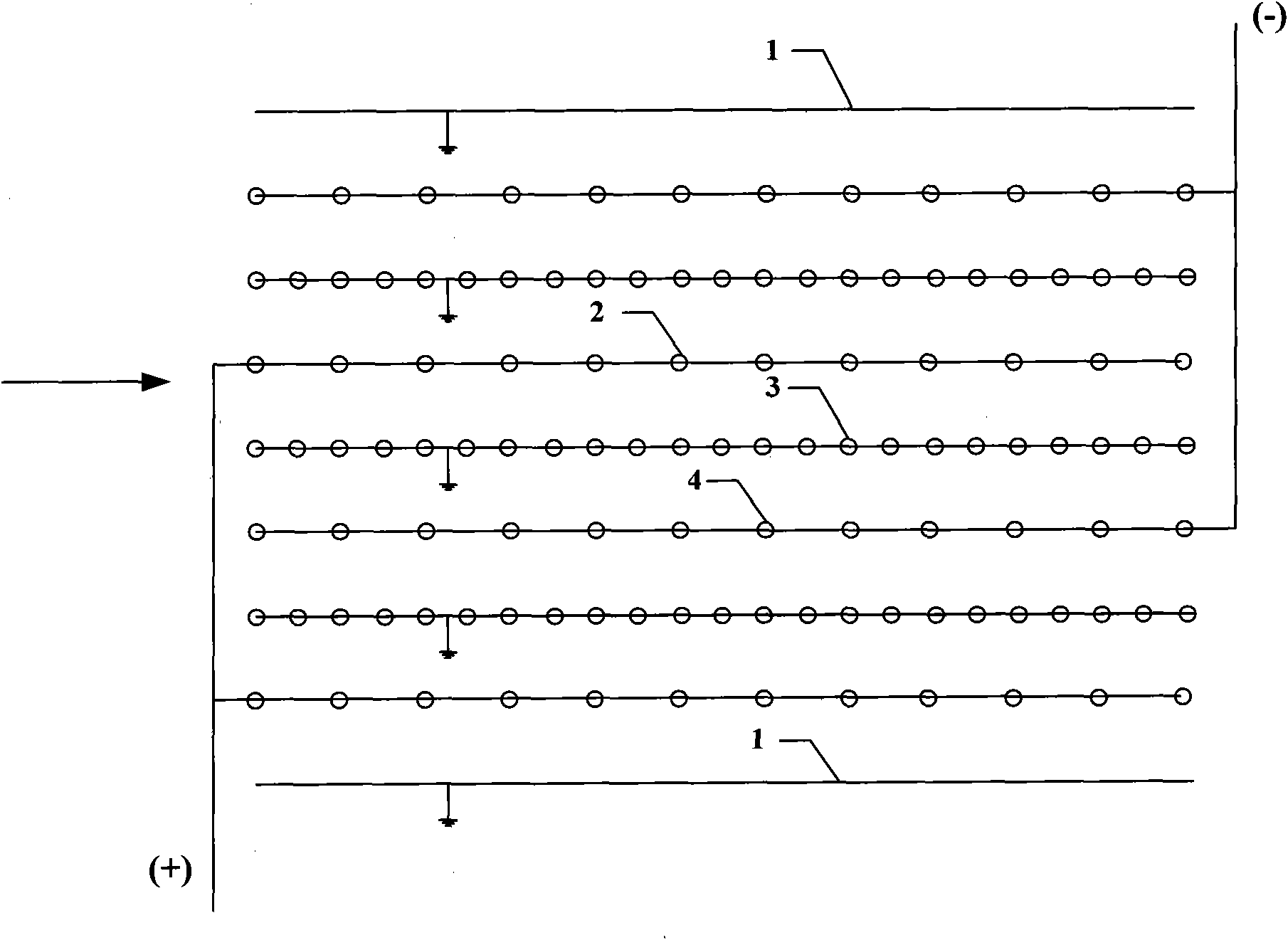

[0022] figure 1 It is a three-dimensional view of the first arrangement of internal polar lines of a bipolar electrostatic particle agglomerator without a partition. figure 1 In the case 1 made of metal, multiple sets of positive discharge electrode wires 2, negative discharge electrode wires 4 and ground electrode wires 3 are arranged. Each ground electrode wire 3 in each group of ground electrode wires 3 is arranged vertically in the dust particle flow direction (i.e. figure 1 The arrow in indicates the direction). A positive discharge electrode line 2 is arranged in parallel above each group of ground electrode lines 3, and a negative discharge electrode line 4 is arranged in parallel underneath it. In this embodiment, the negative discharge electrode wire 4 can also be arranged in parallel above each group of ground electrode wires 3, and the positive discharge electrode wire 2 can be arranged in parallel below it. figure 1 Shown is the schematic diagram of the ground electr...

Embodiment 2

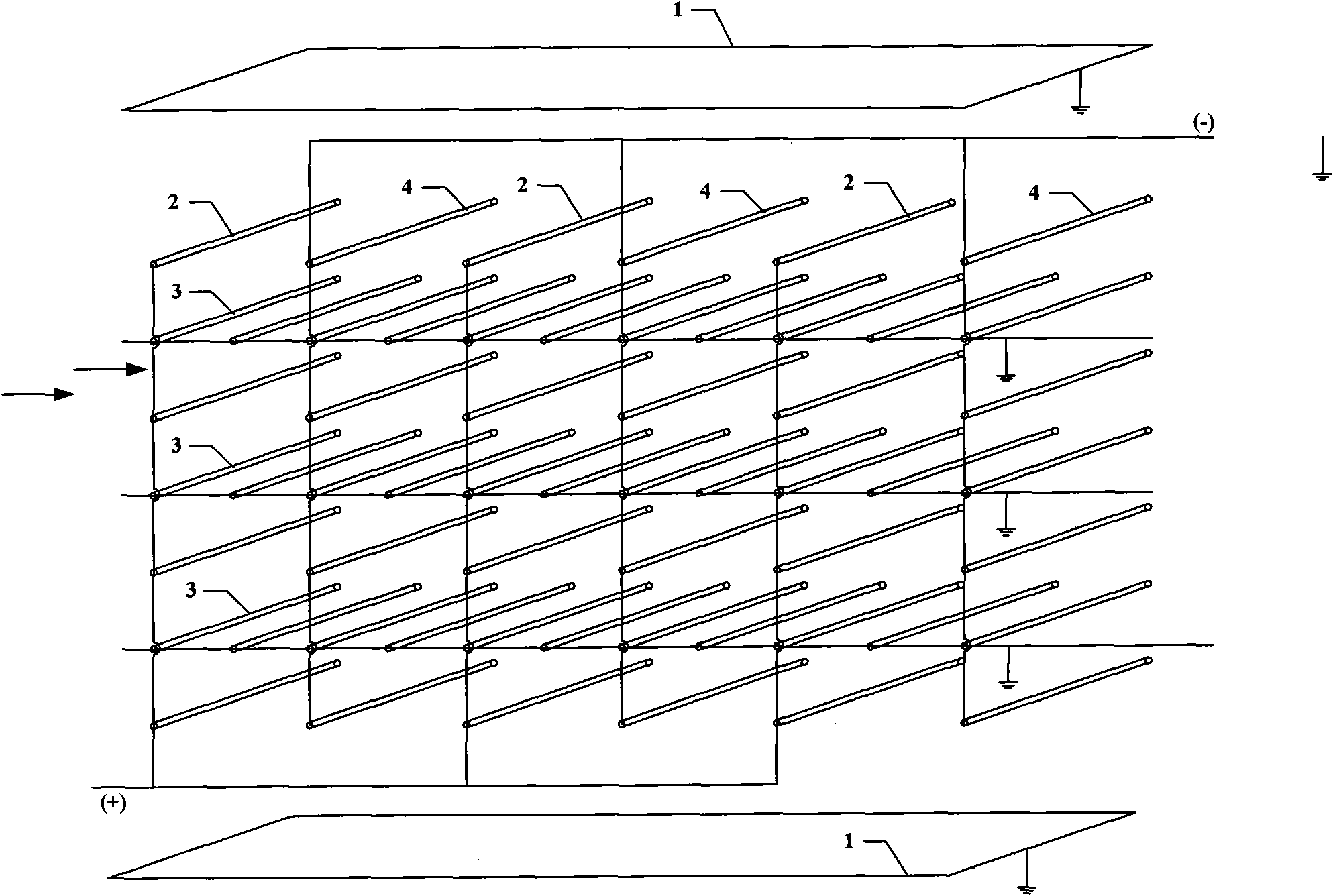

[0026] image 3 It is a three-dimensional view of the second arrangement of internal polar lines of the bipolar electrostatic particle agglomerator without partitions. image 3 In the case 1 made of metal, multiple sets of positive discharge electrode wires 2, negative discharge electrode wires 4 and ground electrode wires 3 are arranged. Each ground electrode wire 3 in each group of ground electrode wires 3 is arranged vertically in the dust particle flow direction (i.e. image 3 The arrow in indicates the direction). A positive discharge electrode line 2 and a negative discharge electrode line 4 are alternately arranged above and below the ground electrode line 3 in parallel. That is, above the ground electrode line 3, both the positive discharge electrode line 2 and the negative discharge electrode line 4 are arranged. The positive discharge electrode line 2 and the negative discharge electrode line 4 are arranged alternately, and the positive discharge electrode line 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com