Viscous heat insulating pad and manufacturing method thereof

An insulating pad and sticky technology, applied in the field of viscous heat insulating pad and its manufacture, can solve the problems of occupying plane space, destroying the wall structure and appearance, slippery hand falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings.

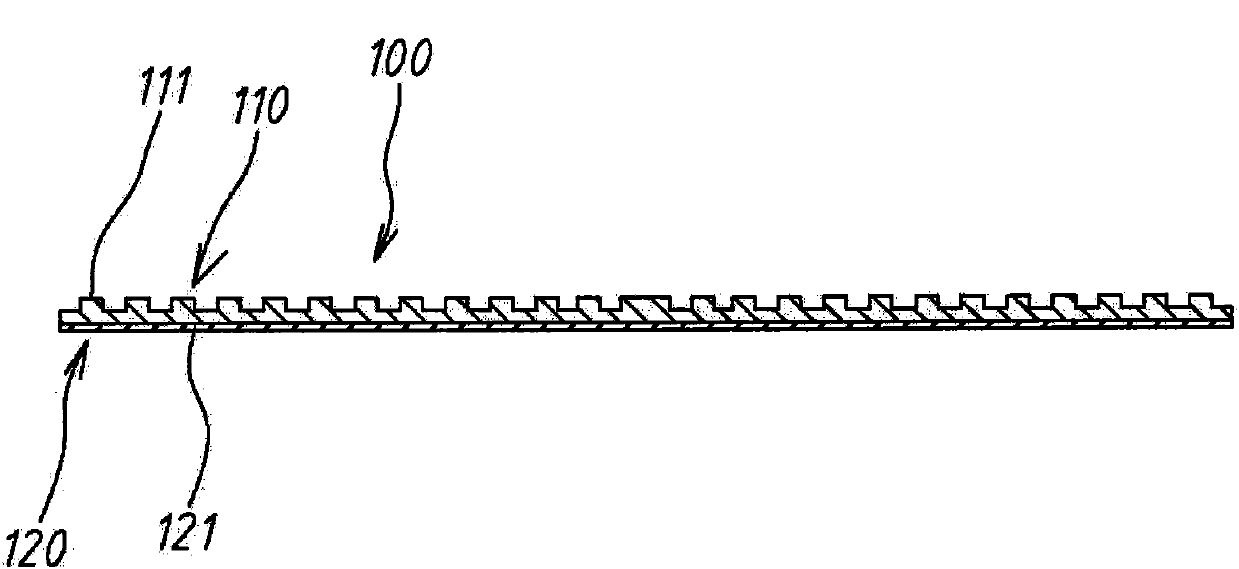

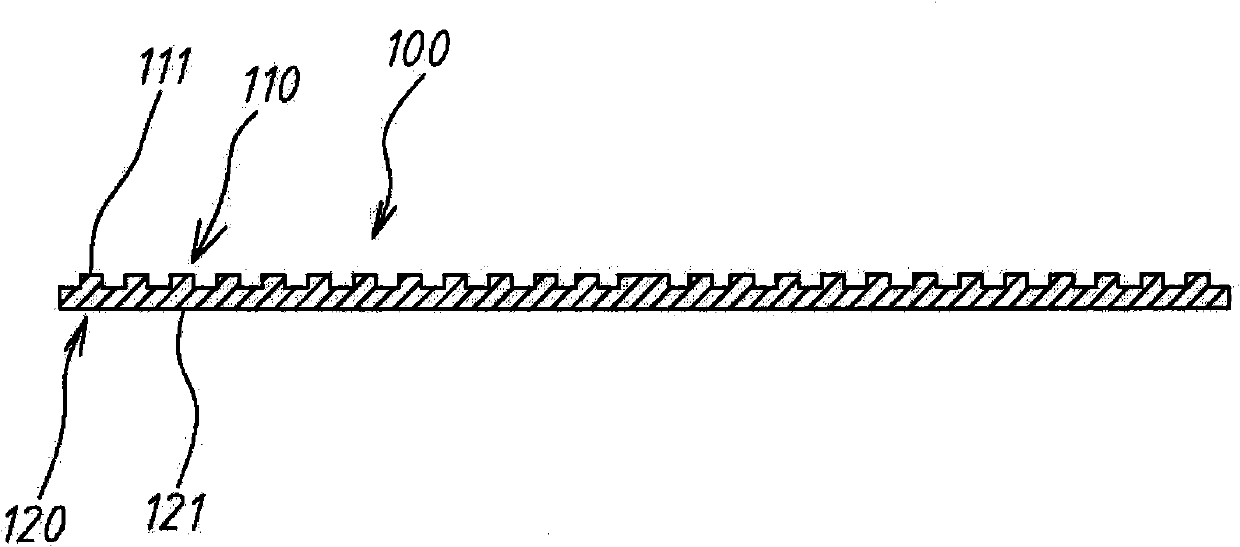

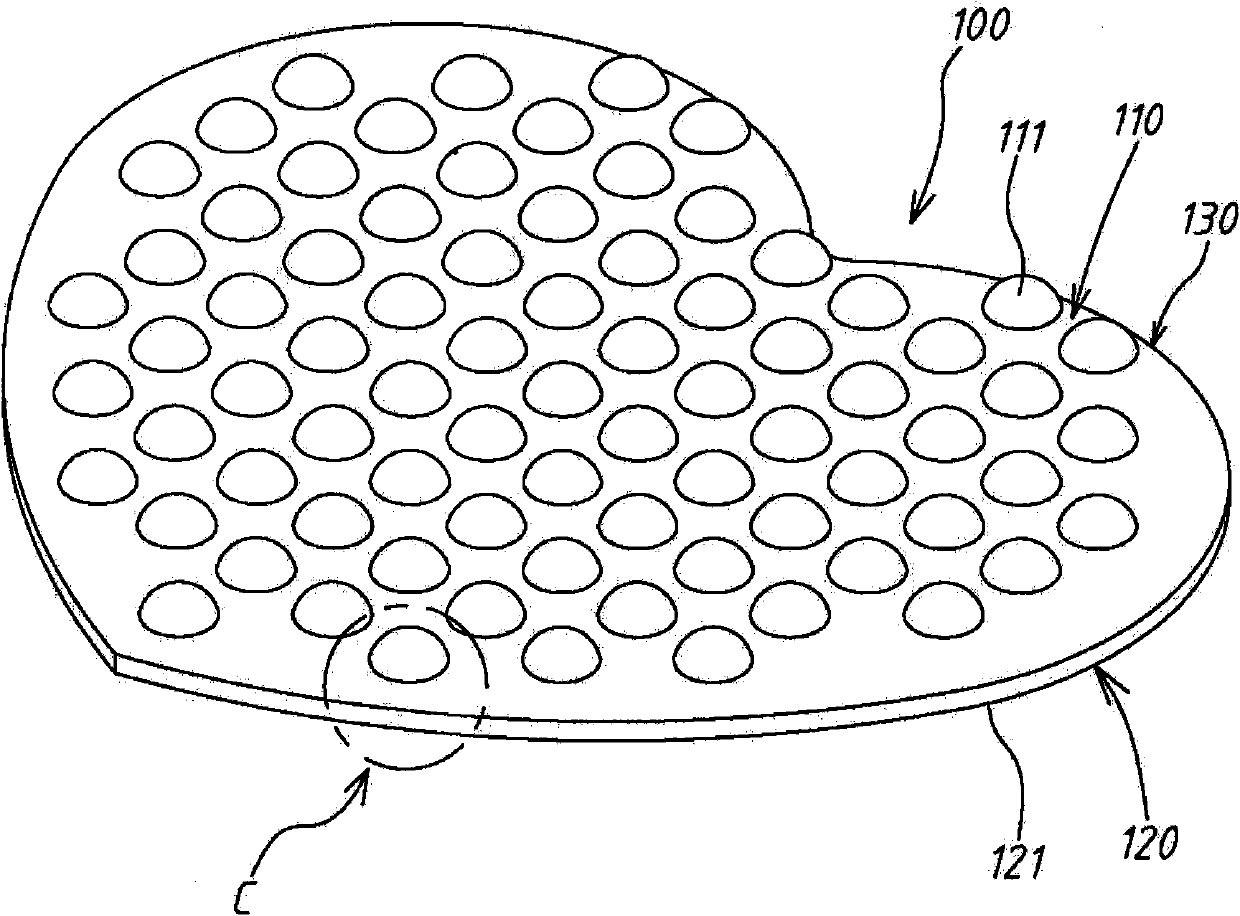

[0026] see Figure 1 to Figure 3 , which shows the structure of the adhesive heat insulation pad according to a first embodiment of the present invention. As shown in the figure, the heat insulation pad 100 according to an embodiment of the present invention is a soft pad body 130 made of, for example, silicone, which can be twisted or bent into any shape, so as to be suitable for use in different shapes of dishes and other utensils. . The soft pad body 130 of the heat insulation pad 100 has a first surface 110 and a second surface 120 opposite to each other. Wherein, the first surface 110 has a plurality of protrusions 111 such as protrusions or ridges, which have anti-slip and anti-scald effects; and the second surface 120 has an adhesive surface 121, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com