Cap and nozzle assembly

A technology of nozzles and components, applied in the field of caps and nozzles, can solve problems such as difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

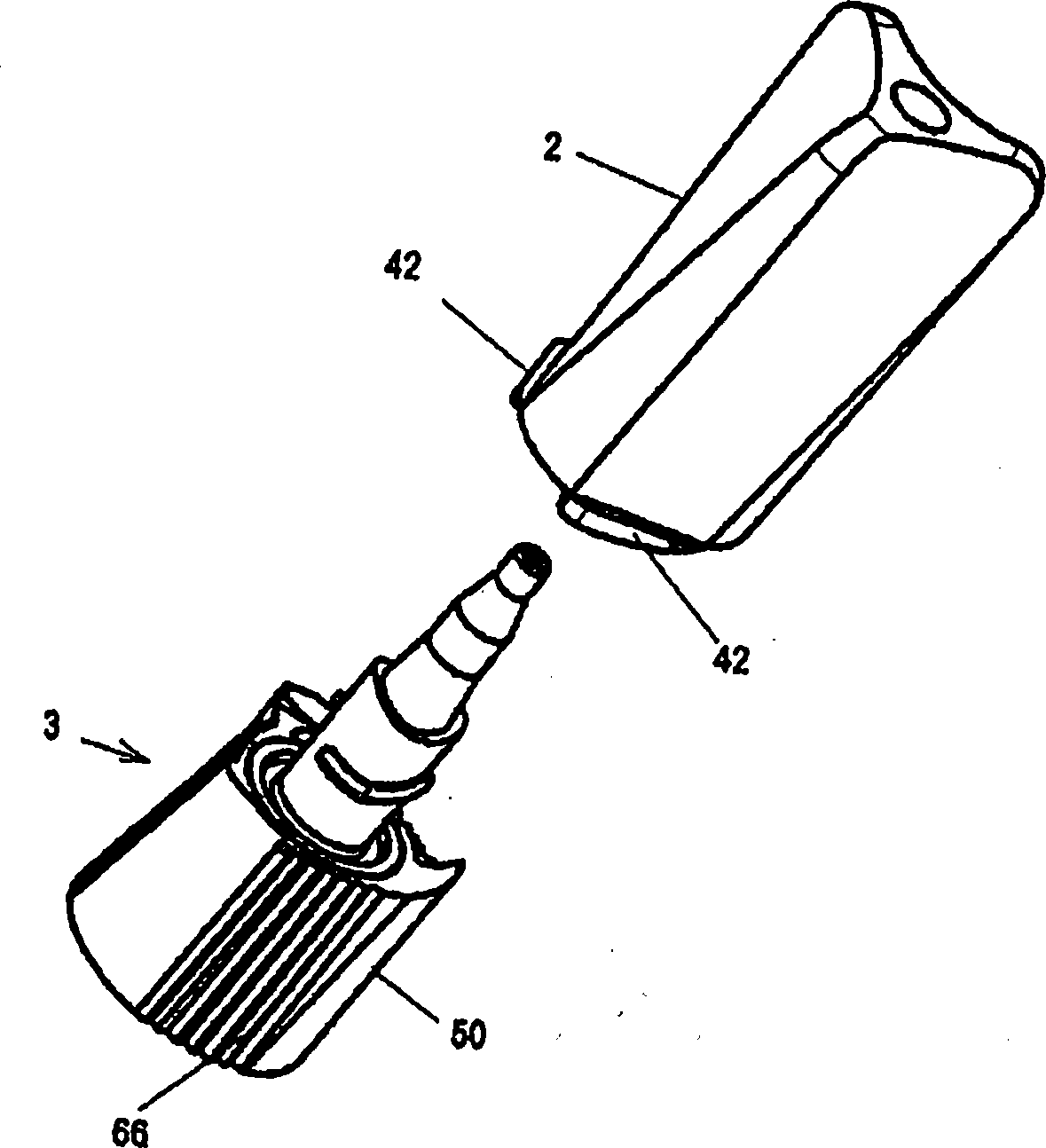

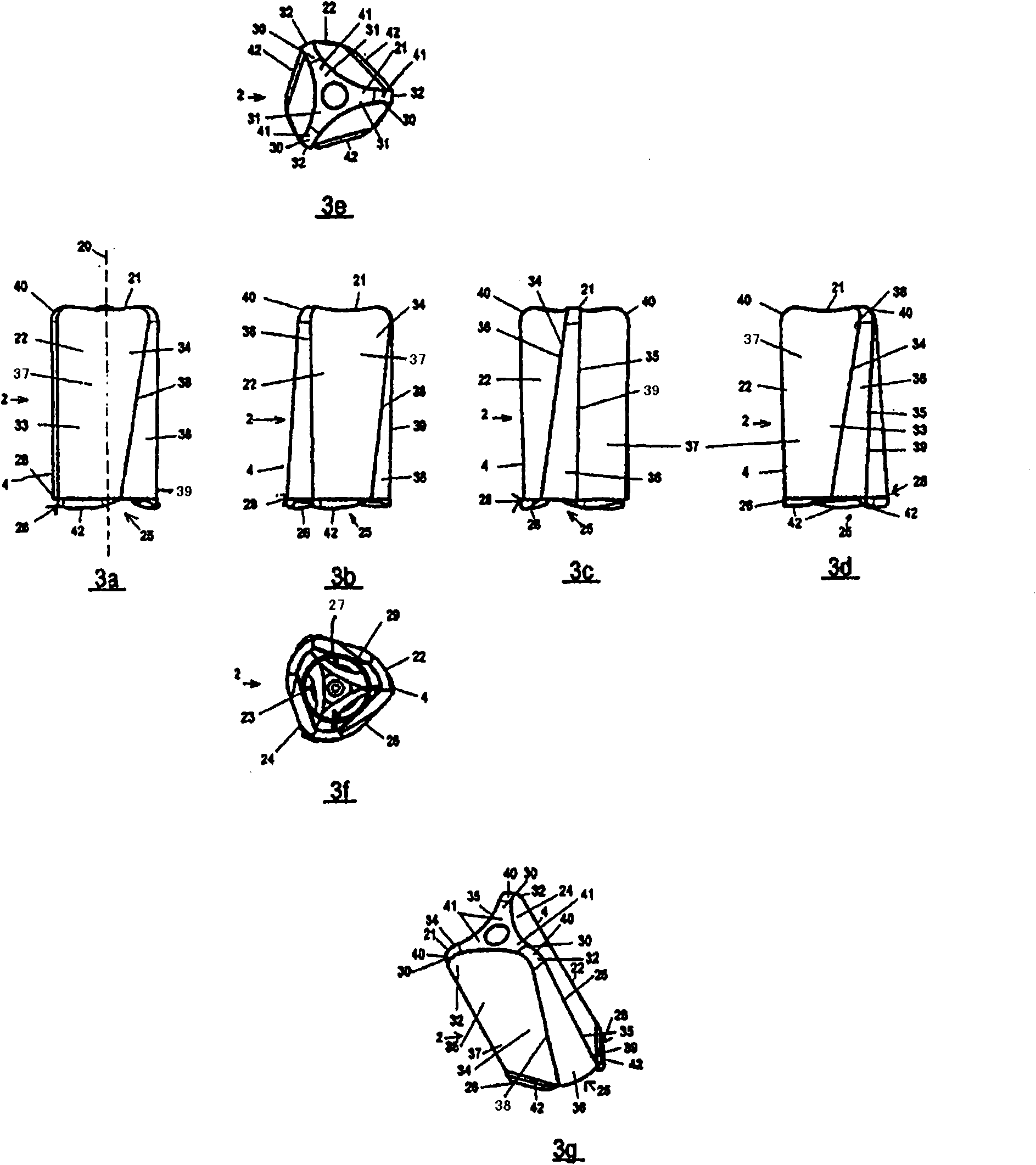

[0060] refer to image 3 In the embodiments shown in a-g, the cap 2 forms part of the cap / nozzle assembly 1 . The cap 2 is used to fit onto the nozzle 3 . The cover 2 has an elongated cover body 4 with a longitudinal axis 20 . The lid 2 has a first closed end 21 and at least one side wall 22 which in this embodiment is a continuous side wall integrally formed with and depending from the closed end 21 forming a continuous or annular wall. In this embodiment, side wall 22 is one wall that is looped to join itself. As shown, it may be substantially circular, but other desired shapes are also possible. best as image 3As shown in f, the side wall 22 has an inner surface 23 and an outer surface 24 . The side walls 22 form a housing 25 defined (delimited) by an inner surface 23 of the cover body 4 . The side wall 22 also forms an open end 26 at a base end 28 of the cover body 4 with an opening 27 between the inner surface 23 and the outer surface 24 . The mouth 27 is effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com