Light auto-walk vibration compressing roll

A vibratory compaction, self-propelled technology, applied in the direction of transmission, gear transmission, soil protection, etc., can solve the problems of high labor intensity of the operator, adjusting the walking speed, and small scope of application, and achieves good compaction effect. The effect of changing walking speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

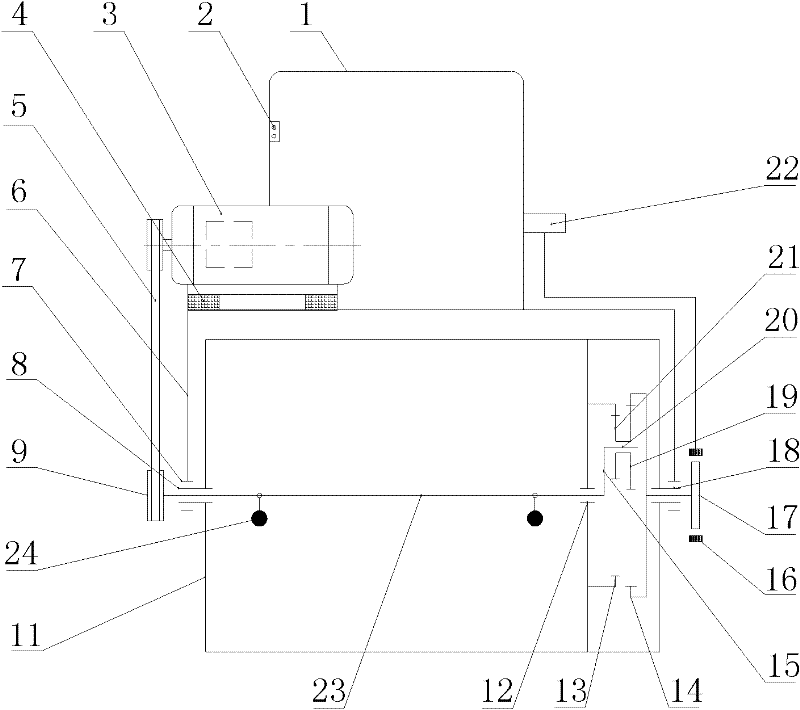

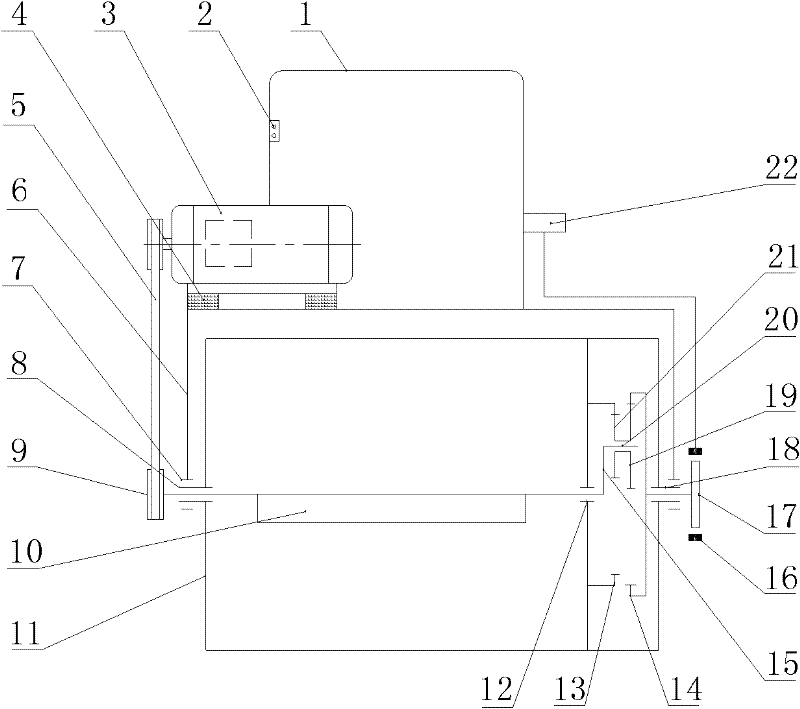

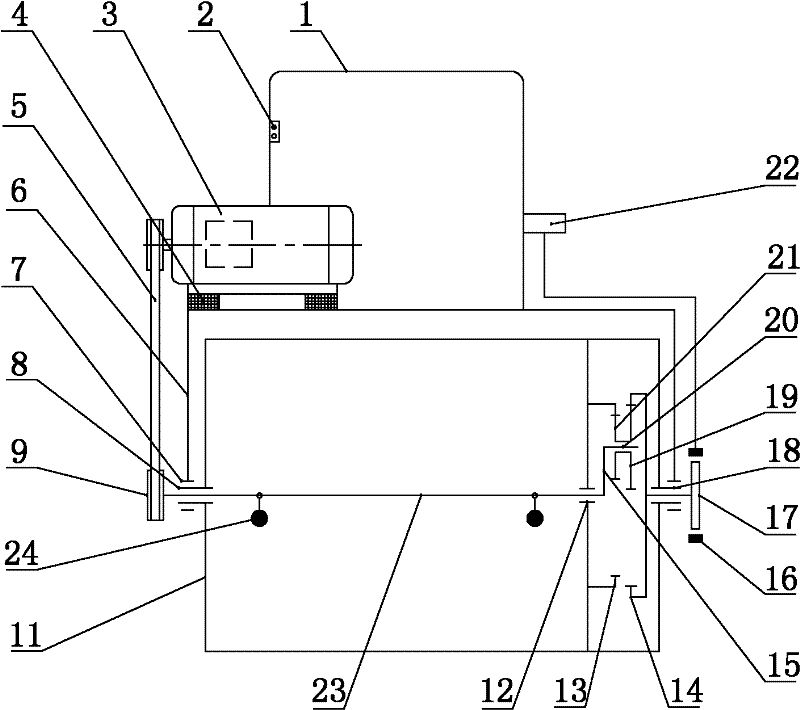

[0023] like figure 1 As shown, the light-duty self-propelled vibratory compacting roller of the present invention includes a frame 6 and a handrail 1 and a motor 3 arranged on the frame 6, the handrail 1 is provided with a switch 2, wherein, on the frame 6, the The slewing pairs 8 and 12 are connected with transmission shafts adopting an eccentric mechanism—an eccentric block 24 is consolidated on the transmission shaft 23, and one end of the transmission shaft 23 adopting an eccentric mechanism is connected with the transmission mechanism set on the motor 3, and the transmission shaft 23 The other end is connected with the speed regulating mechanism; a roller body 11 is sleeved on the transmission shaft 23, and the roller body 11 is connected with the frame 6 through the rotary pair 7; the brake 16 on the speed regulating mechanism is connected to the armrest The brake controller 22 on the 1 is connected to control the gear movement of the speed regulating mechanism; the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com