Structure for improving dark bands of backlight module and method thereof

A technology of backlight module and dark band is applied in the field of improving the structure of the dark band of the backlight module, which can solve the problem of limited effect and achieve the effect of eliminating the dark band.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

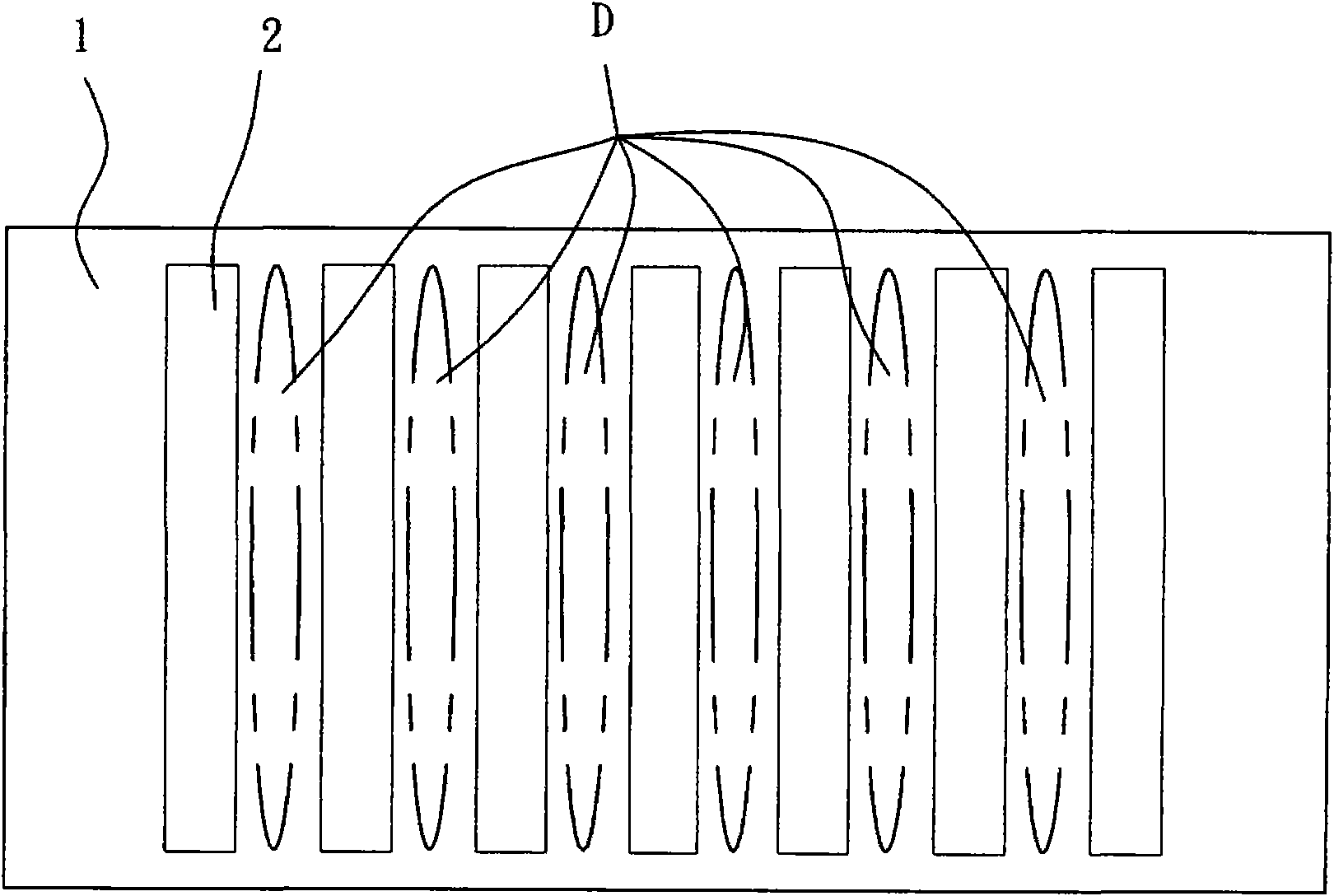

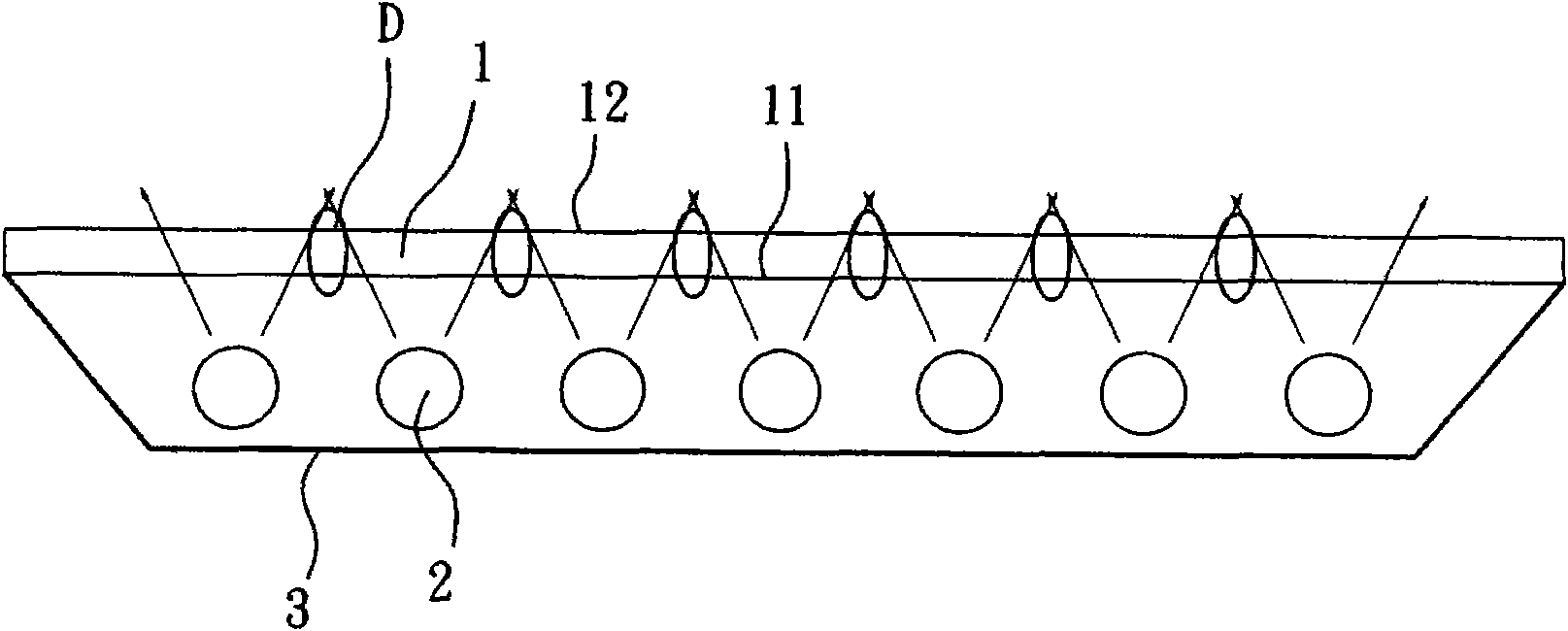

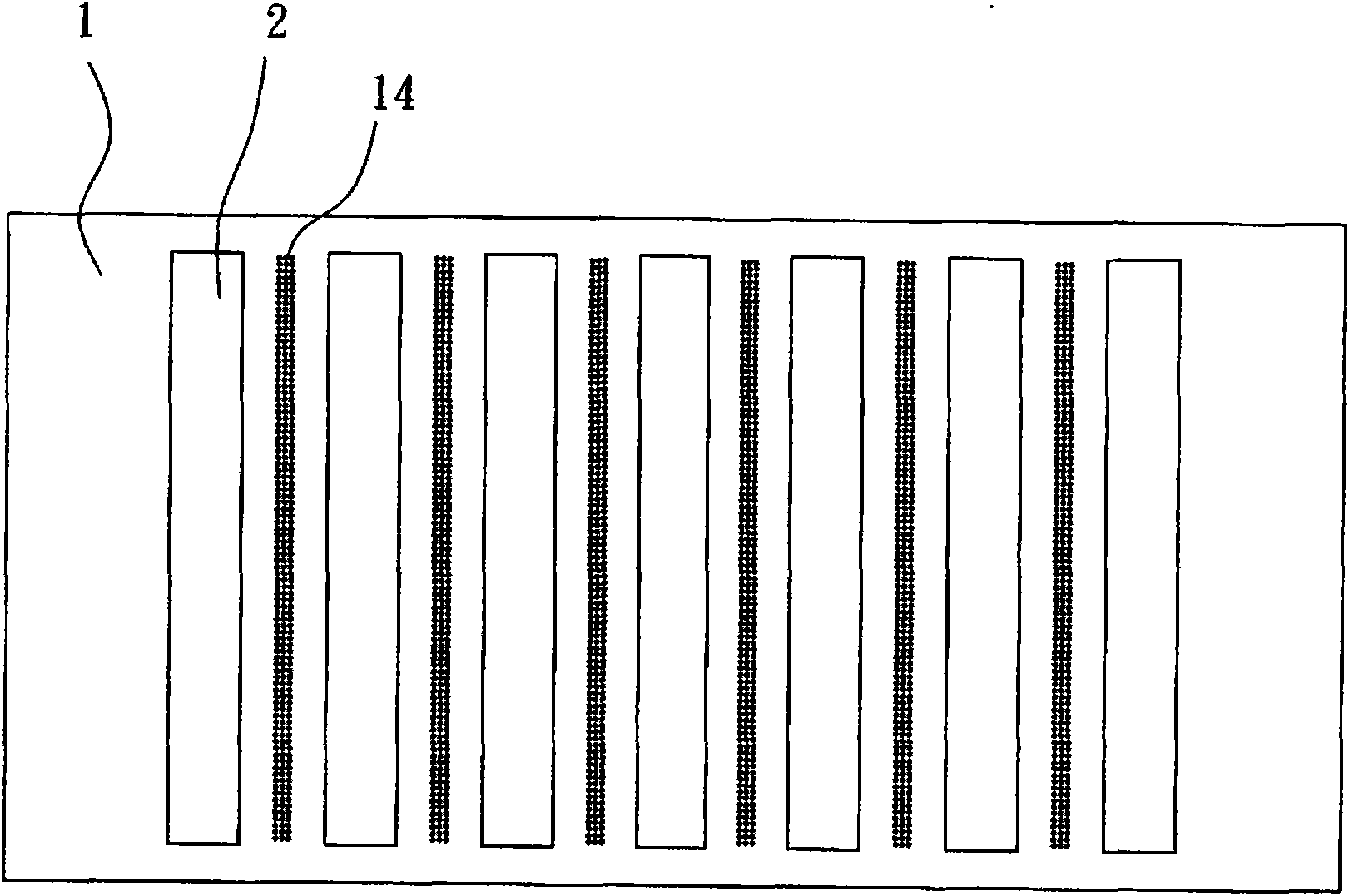

[0028] The feature of the present invention is to improve the structure of the diffusion plate installed in the backlight module, so that the area between the two light sources with low light output can obtain more original light sources for compensation, thereby achieving the effect of reducing or even eliminating dark bands.

[0029] The technical means of the present invention is to arrange a plurality of light sources at the position facing the light-incident surface of the diffusion plate on the backlight module, wherein, the diffusion plate between the two light sources is distributed with a plurality of minimum thicknesses smaller than the average thickness of the diffusion plate, so that The original light source with a large amount of light can be emitted from the position of the minimum thickness to make up for the lack of light output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com