Vehicle front body structure

A front body and automobile technology, which is applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problem that the torsional stiffness of the front body of the front baffle cannot be utilized, and the local stiffness and strength of the front shock absorber seat cannot be used. Comprehensive consideration of the front baffle, sound insulation, poor heat insulation effect, etc., to achieve the effect of improving NVH performance, improving local stiffness and strength, and improving front torsional stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

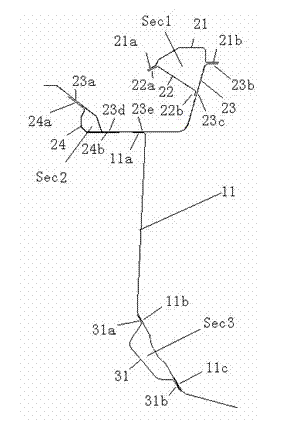

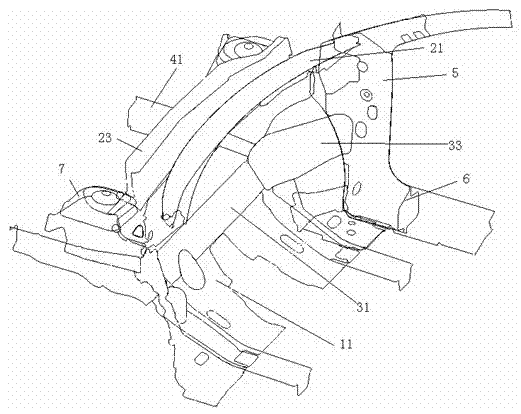

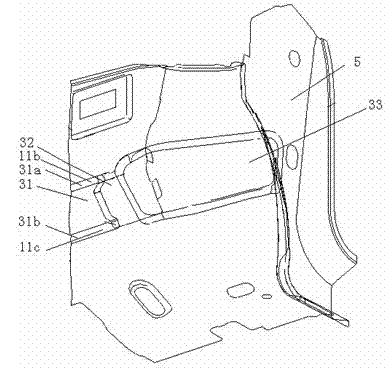

[0018] Such as figure 1 As shown, the automobile front body structure of the present embodiment includes a front baffle plate 11 and a front windshield lower beam assembly, and the front windshield lower beam assembly includes a "U" shaped front windshield lower beam 21, a front windshield lower beam assembly, and a front windshield lower beam assembly. Support plate 22, "U" shaped water tank body 23 and reinforcement beam 24 on the front baffle; The position is welded and fixed with the edge 21b of the front windshield lower beam 21, the edge 21a of the front windshield lower beam 21 is welded and fixed with the edge 22a of the front windshield lower beam lower support plate 22, and the edge 22b of the front windshield lower beam lower support plate 22 is welded and fixed. The position is welded and fixed with the 23c part of the water tank body 23, so that a sealed cavity structure Sec1 extending along the width direction of the vehicle body is formed between the water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com