Barrel supporting part of washing machine

A support and washing tub technology, applied in other washing machines, washing devices, textiles and paper making, etc., can solve problems such as excessive movement of washing tubs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] While the invention may be embodied in many forms, it should be understood from one or more embodiments shown in the drawings and described in detail herein that this disclosure should be considered as an example of the principles of the invention rather than as an illustration. It is intended to limit the invention to the illustrated embodiments.

[0015] washing tub support

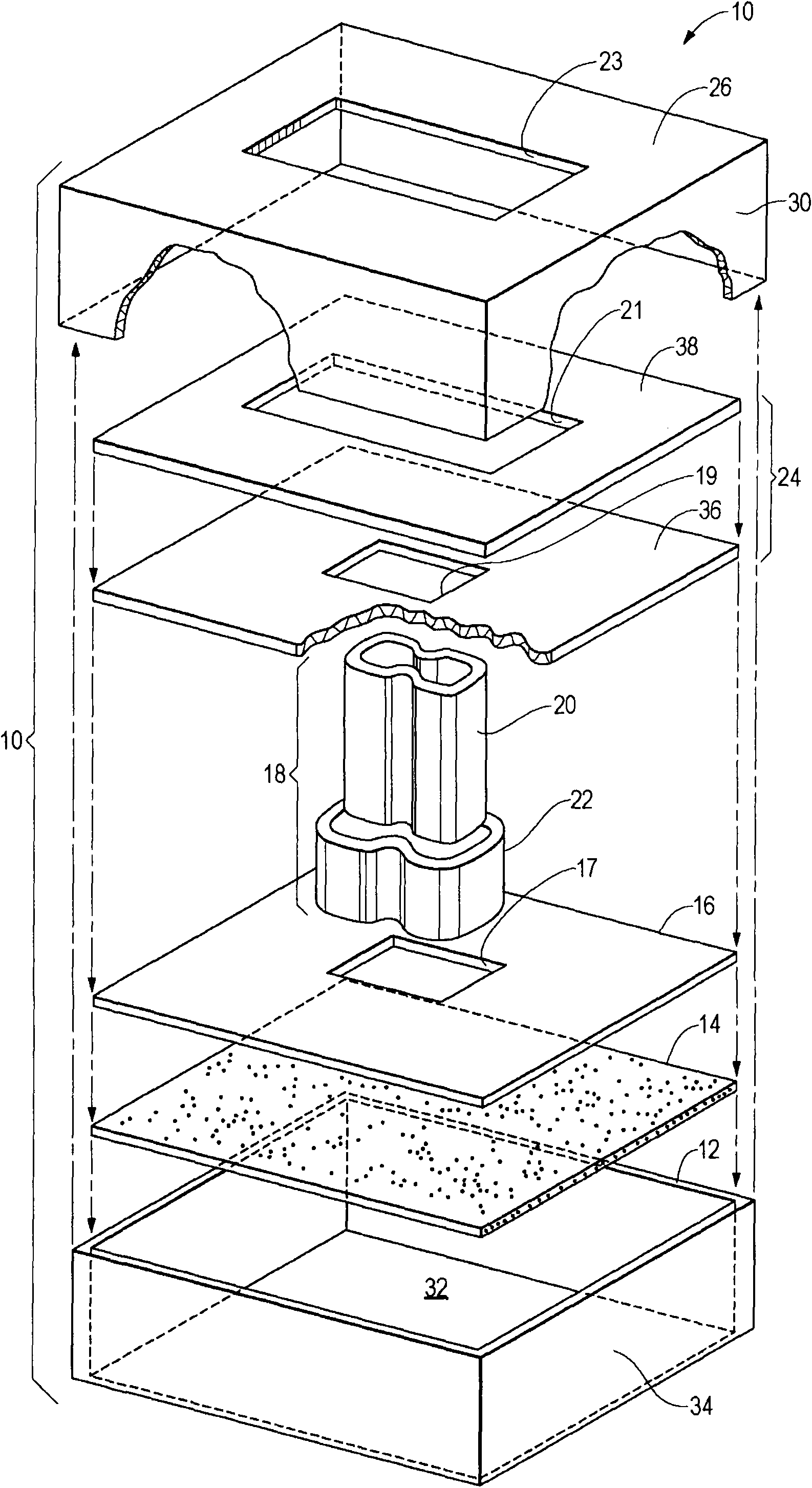

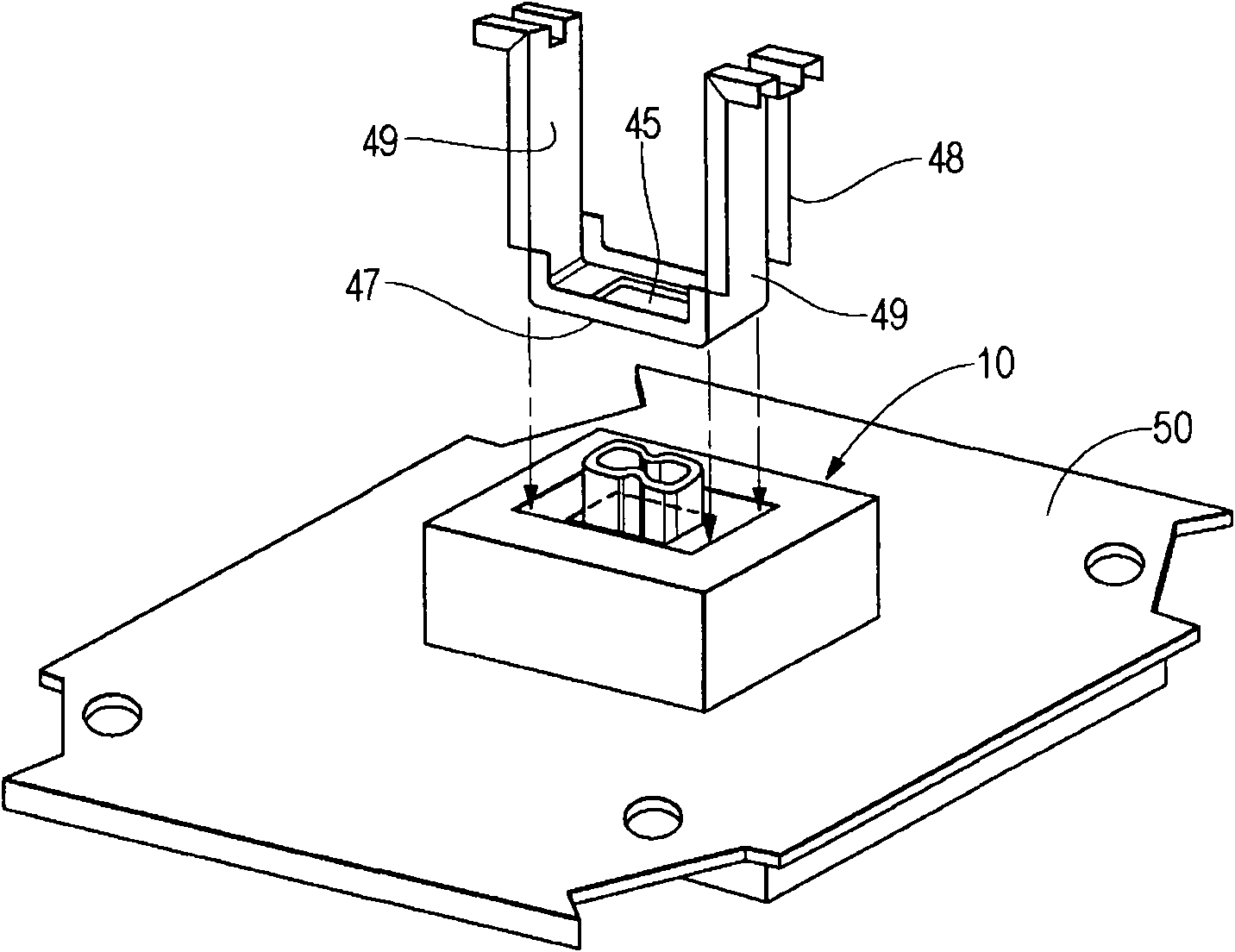

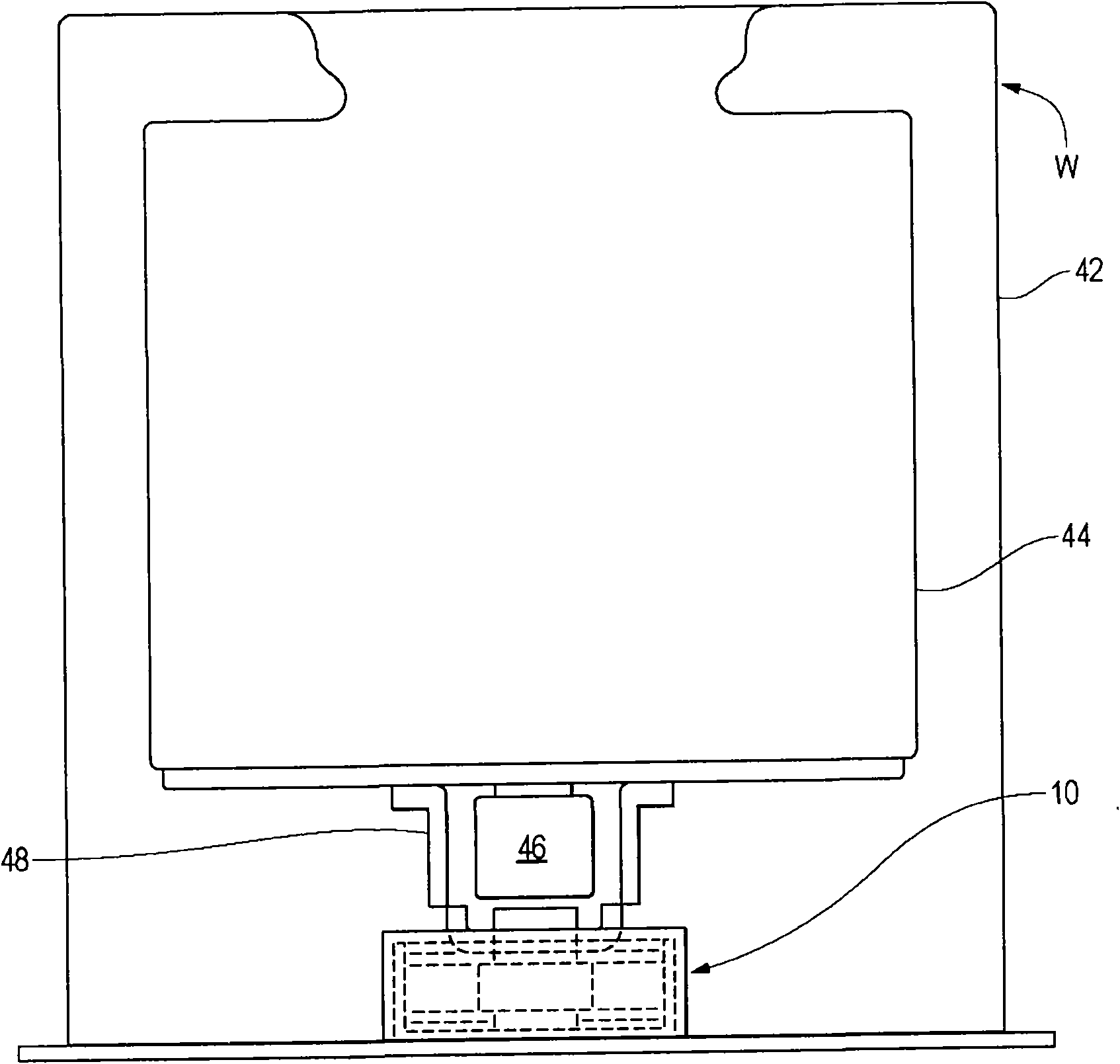

[0016] Turning to the drawings, one embodiment of the present invention is shown: a washtub support 10 for use with a top loading washing machine W having a washtub 44, suspended below the washtub 44. A motor 46 , and a U-shaped bracket 48 attached to the bucket 44 and surrounding the motor 46 . Such as figure 1 As best shown in , the wash tub support 10 includes a bottom tray 12, a rectangular bumper 14 that fits within the bottom tray 12, a rectangular bottom that fits within the bottom tray 12 to position and hold the inner legs 20 in place. Insert 16 , strut assembly 18 including inner str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com