Dual-working-platform surface fault automatic detector for flexible printed circuit

A technology of printed circuit and double worktable, applied in the field of inspection machines, can solve the problems of high missed inspection rate, eye fatigue, high labor intensity, etc., and achieve the effect of accurate defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

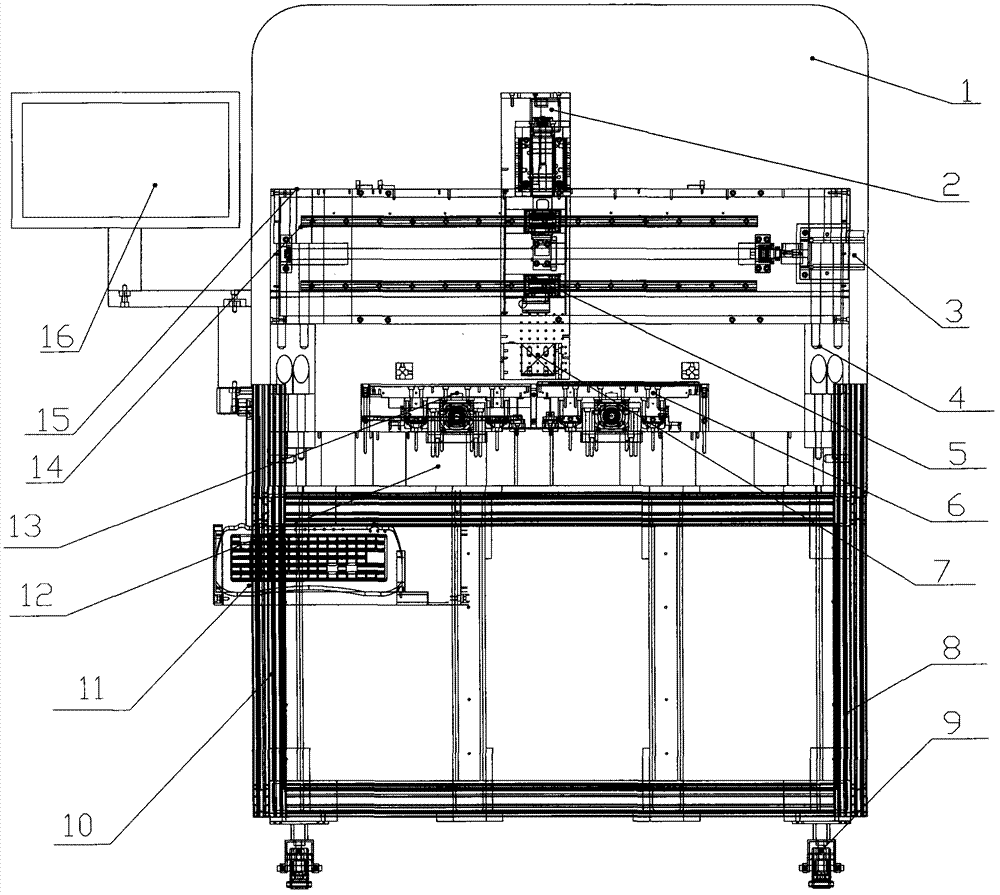

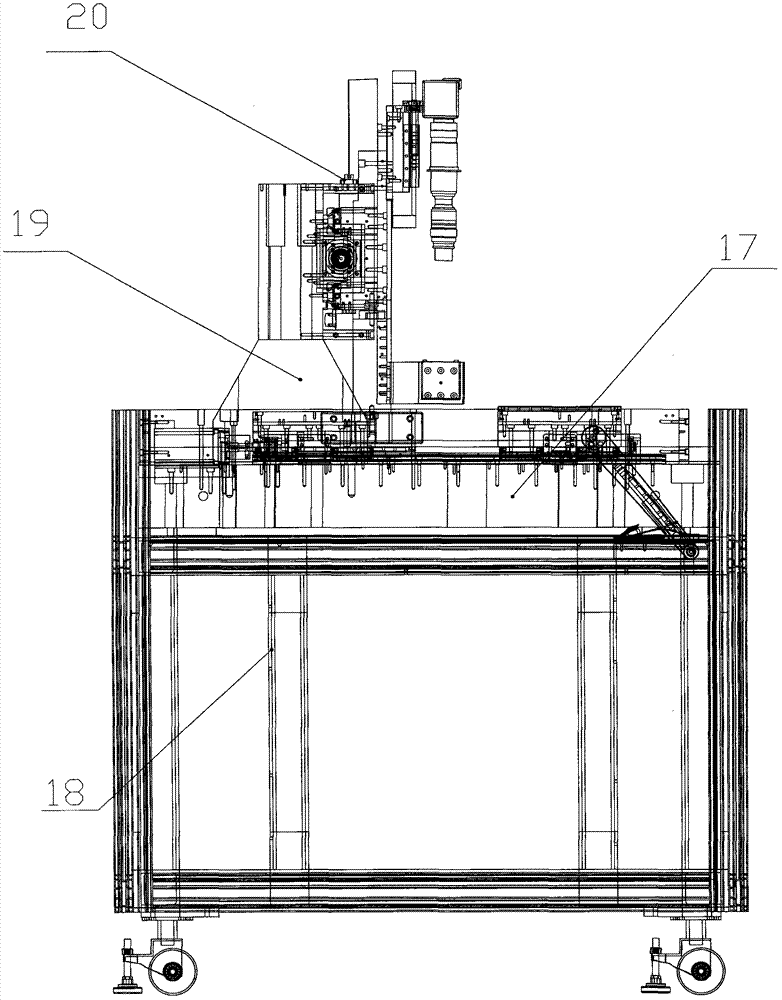

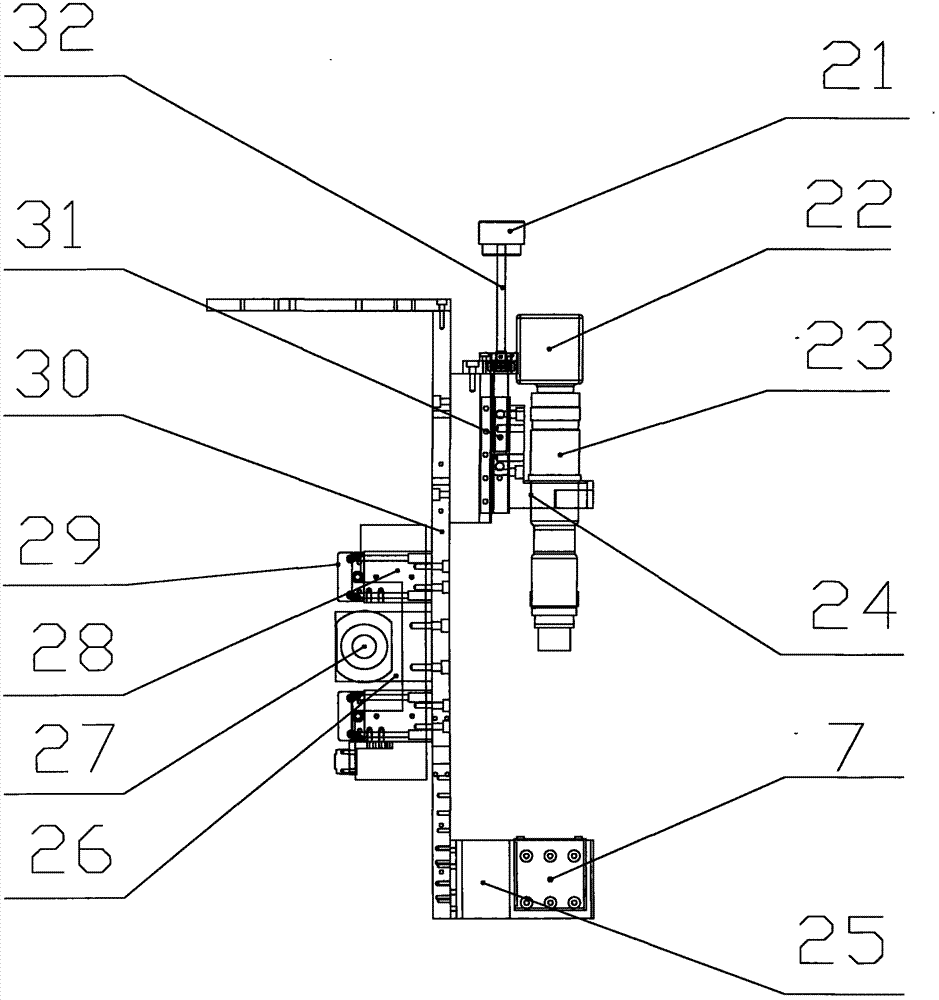

[0019] The related structure of the present invention mainly includes the following components (or devices): outer protective upper cover 1, optical system 2, X-axis servo motor 3, gantry support marble 4, Z-axis support mechanism 5, Y-axis motion mechanism-6, visual Detection light source system 7, outer protective lower cover 8, machine support casters 9, fixed protective plate 10, mouse and keyboard mechanism 11, marble platform 12, Y-axis movement mechanism 13, X-axis direction photoelectric induction system 14, X-axis outer protection Board 15, display 16, side protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com