Modular quickly-spliced unmanned aerial vehicle

A rapid splicing, drone technology, applied in the aviation field, can solve the problems of unmanned aerial vehicles being unable to be exchanged in time, quickly, unable to achieve rapid assembly and disassembly, and unable to be put into the task again immediately, and achieve fast, accurate, fast and tight connection. Rigorous design, fast installation and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

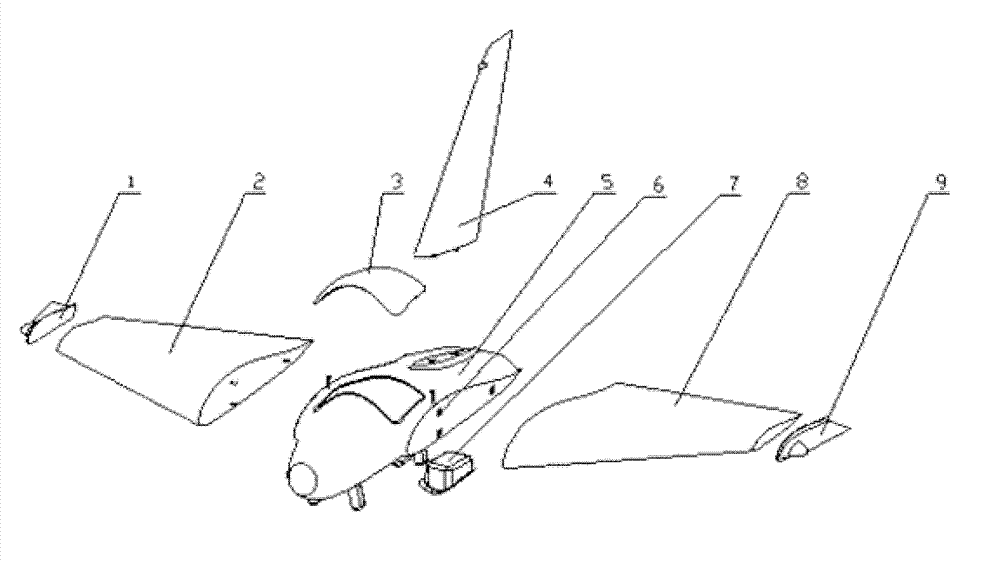

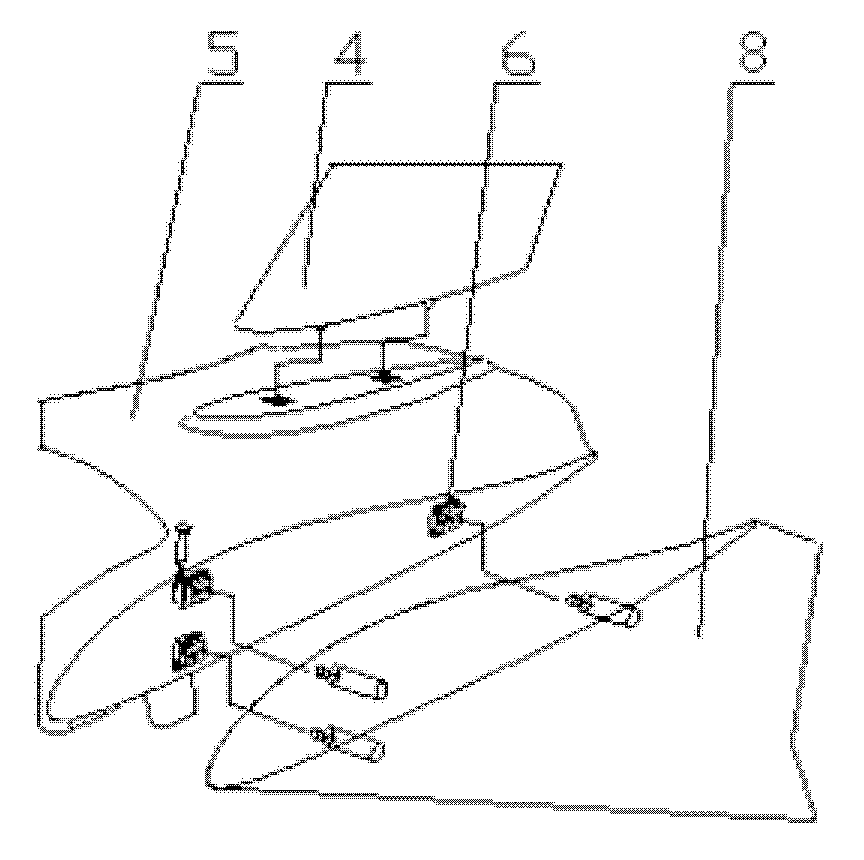

[0026] A modular quick splicing unmanned aerial vehicle includes eight modules and locking devices installed therebetween. Among them, the eight modules are: left wing tip module 1, left wing module 2, hatch cover module 3, vertical module 4, fuselage module 5, parachute module 7, right wing module 8 and right wing tip module 9, the above The location structure of the modules is a prior art, and will not be repeated here.

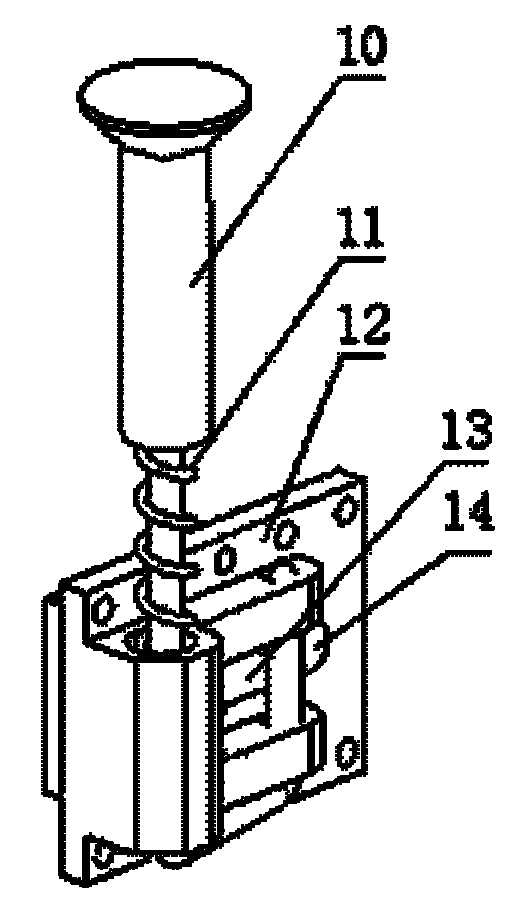

[0027] The above-mentioned modules are all quickly connected with each other by locking devices, and the setting of the locking devices depends on the area connected between the modules. Lock device, one of the locks has a lock for positioning purposes, and the other two do not have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com