Liquid heating vessel and control

A liquid heating container and liquid technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as inaccurate calibration, inaccurate sub-boiling temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Kettle Overview

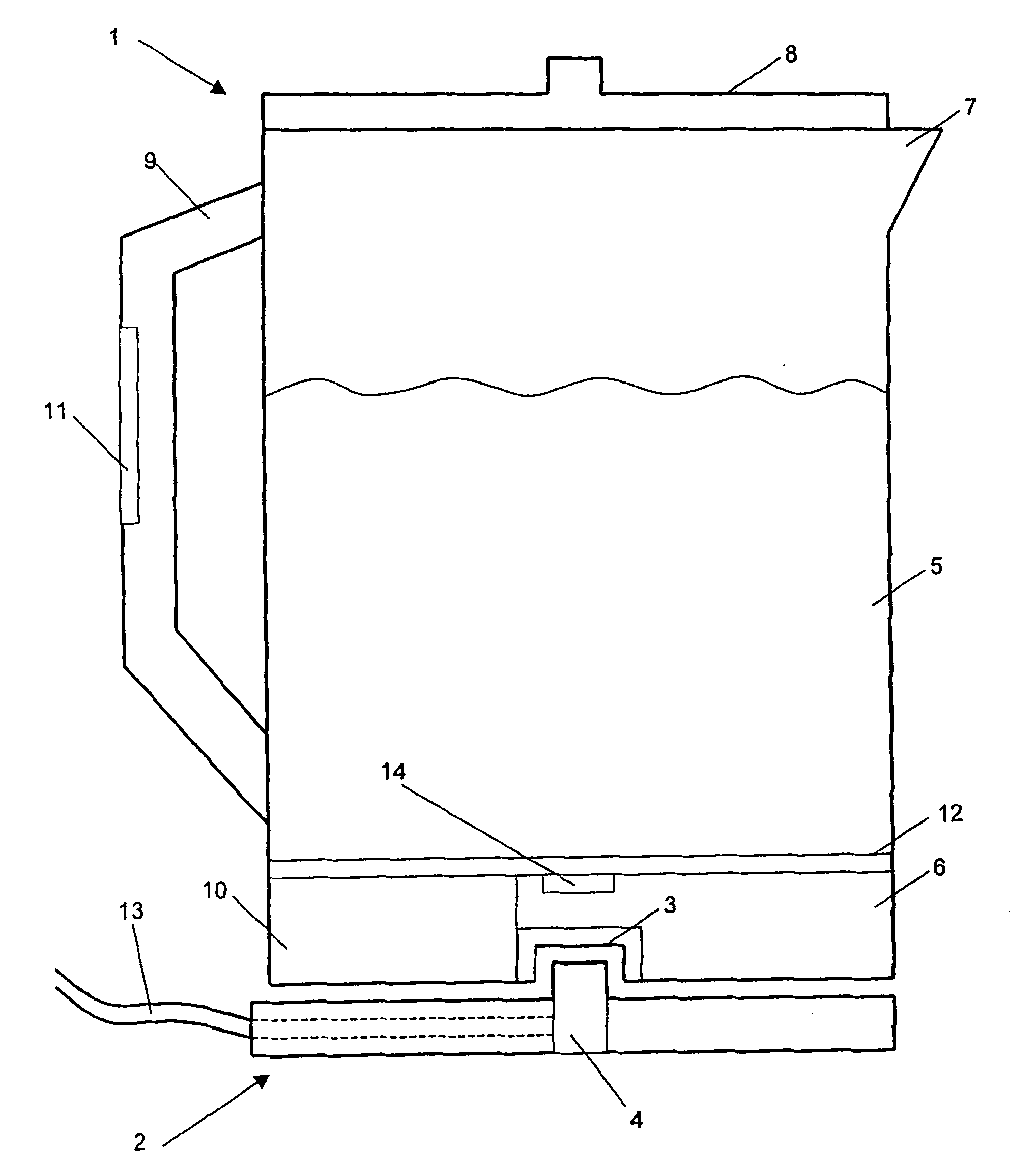

[0036] figure 1 A kettle with electronic controls is shown schematically as an example of a liquid heating vessel to which the invention is applicable. In this example, the kettle is a cordless kettle comprising: a container body 1; and a power base 2 with corresponding body and base wireless connectors 3 and 4 (for example, in patent publication WO-A-94 / 360 degree cordless connector type described in 06185 and / or as sold by Otter Controls Ltd. references CS4 / CS7 (power base socket) and CP7 (equipment plug). The power base is connectable by a power cord 13 to a power socket (not shown).

[0037] The container body 1 comprises: a reservoir 5 for containing water to be heated; and a base portion 6, as well as a spout 7, a cap 8 and a handle 9. The element plate 12 forming the base of the reservoir 5 heats the water and comprises: a heating element on the lower side, ie facing the base part 6 . The element plate 12 can be mounted within the vessel bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com