Liquid discharging apparatus and control method of liquid discharging apparatus

一种液体、设备的技术,应用在液体喷射设备以及液体喷射设备的控制领域,能够解决误排出墨水、波形设计自由度下降、弯液面振动放大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred modes for carrying out the present invention will be described with reference to the drawings and the like. In the embodiments described below, various limitations are made as preferred specific examples of the present invention, but the scope of the present invention is not limited to these forms unless the present invention is particularly limited in the following description. In addition, in this embodiment, an inkjet type recording apparatus (hereinafter referred to as "printer") is taken as an example of a liquid ejection device, and an inkjet type recording head (hereinafter referred to as "printer") is taken as an example of a liquid ejection head. as "recording head") as an example.

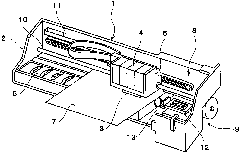

[0022] figure 1 It is a perspective view for explaining the configuration of the printer 1 . This printer 1 includes, inside a housing 2, a carriage 5 on which a recording head 3, which is a type of liquid ejection head, is mounted, and an ink cartridge 4 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com