Assist handle spring design for constant return velocity

一种扶手、主弹簧的技术,应用在扶手组件领域,能够解决扭簧没有呈现扭矩曲线等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

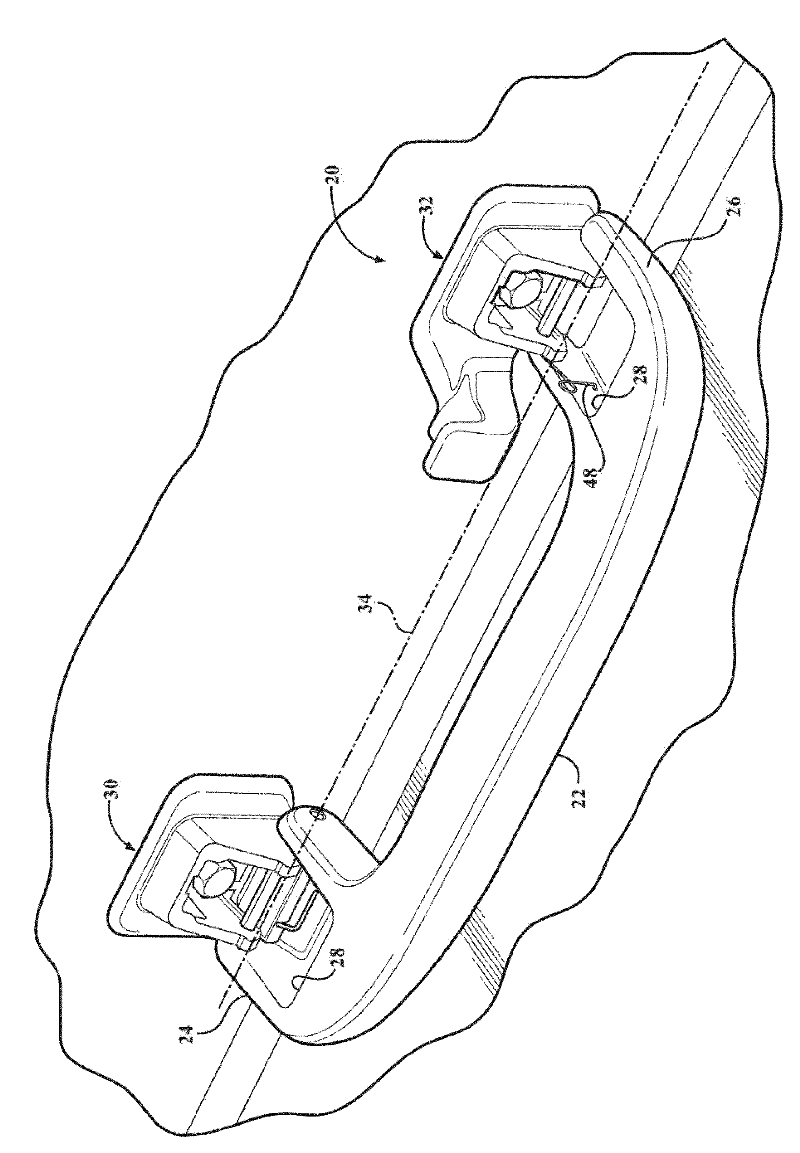

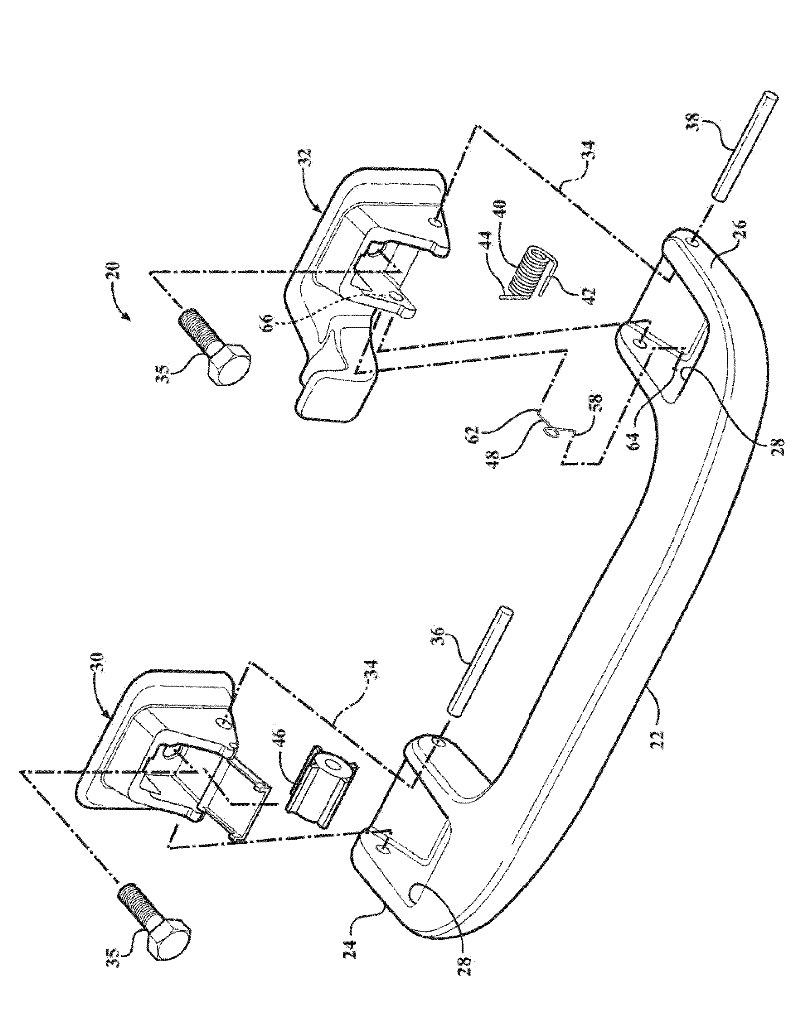

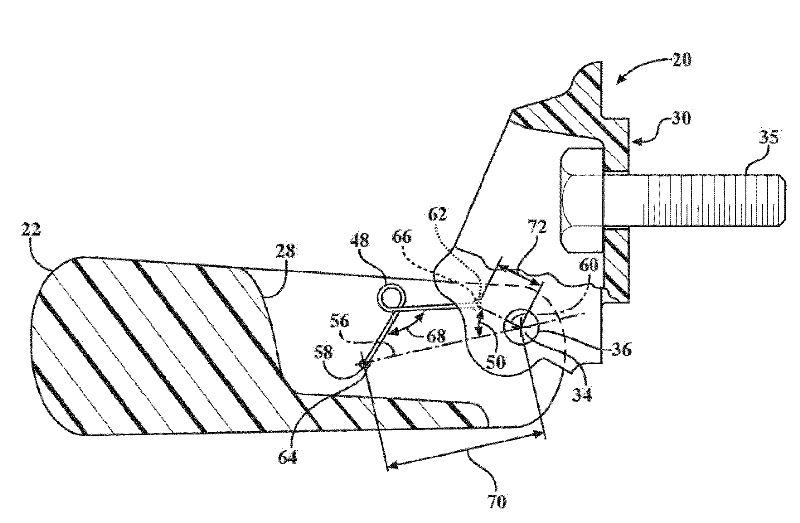

[0052] Referring to the Figures, wherein like numerals indicate like parts throughout the views, an armrest assembly is shown generally at 20 . The armrest assembly 20 is disposed in the interior of the passenger compartment of the automobile. A passenger can grasp the armrest assembly 20 to facilitate entry into and / or exit from the vehicle cabin.

[0053] refer to figure 1 and 2 , the armrest assembly 20 has a main body 22 . The body 22 has a first end 24 and a second end 26 . The first end portion 24 and the second end portion 26 are disposed at opposite ends of the body 22 along the longitudinal axis of the body 22 . The body 22, including the first end 24 and the second end 26, may be configured in any suitable manner to suit the vehicle and any ergonomic requirements. As shown, the body 22 has a generally rounded rectangular cross-section with a first end 24 and a second end 26 extending laterally from the body 22 in a coplanar fashion. As shown, both the first end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com