Flame stabilizing device and method for supporting plate with cavities

A flame stabilization and support plate technology, which is applied in the combustion method, combustion chamber, combustion equipment, etc., can solve the problems of increasing the overall weight of the afterburner due to the increase of flow loss, and achieve the expansion of the circumferential flame coverage area, the simple structure, and the expansion of the flame. Effect of Radial Coverage

Inactive Publication Date: 2015-01-21

BEIHANG UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to overcome the existing technical deficiencies, increase the vortex area, expand the radial coverage area of the flame, and then increase the engine afterburner without significantly increasing the flow loss and the overall weight of the afterburner. Thrust and afterburner work efficiency, while taking into account the simple structure and easy maintenance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

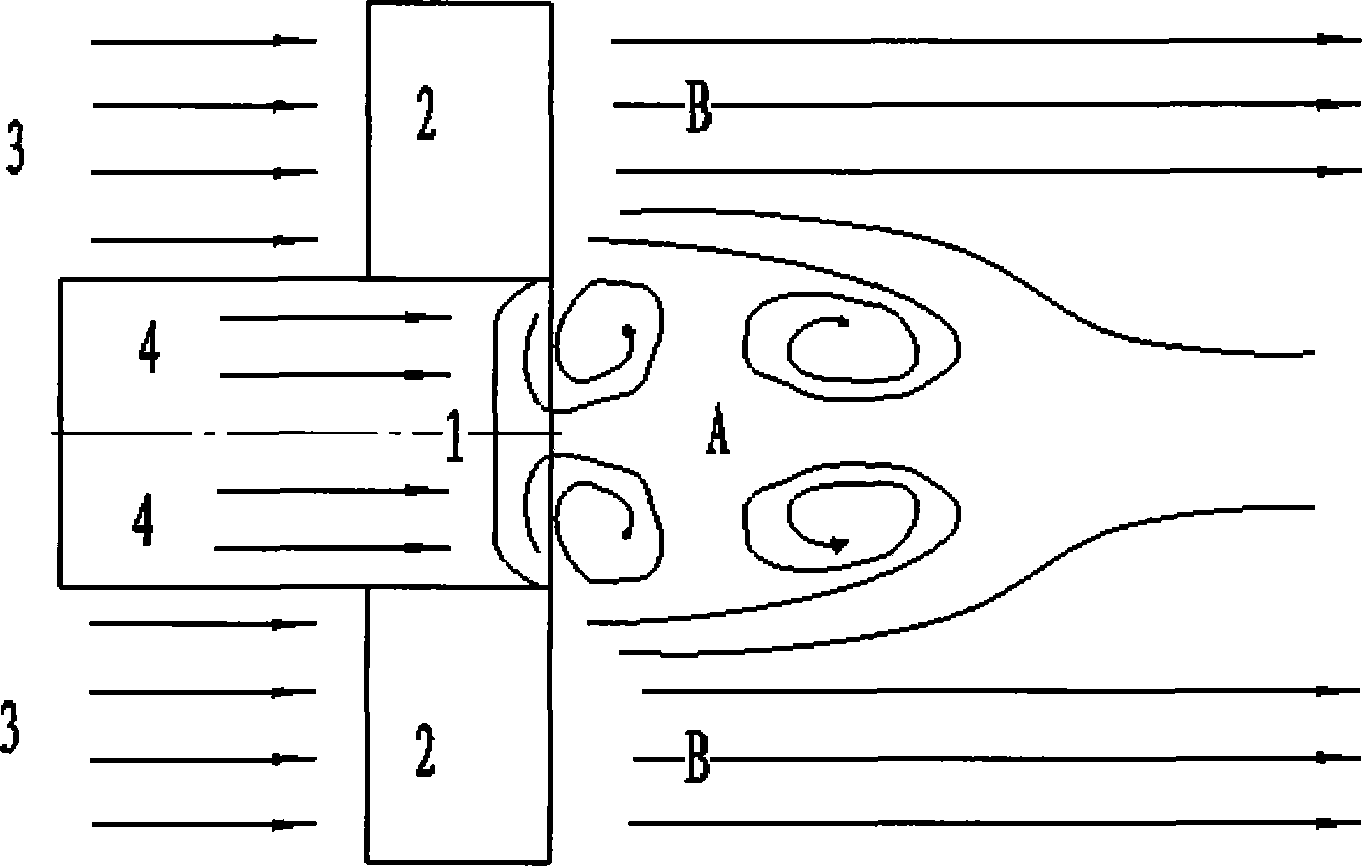

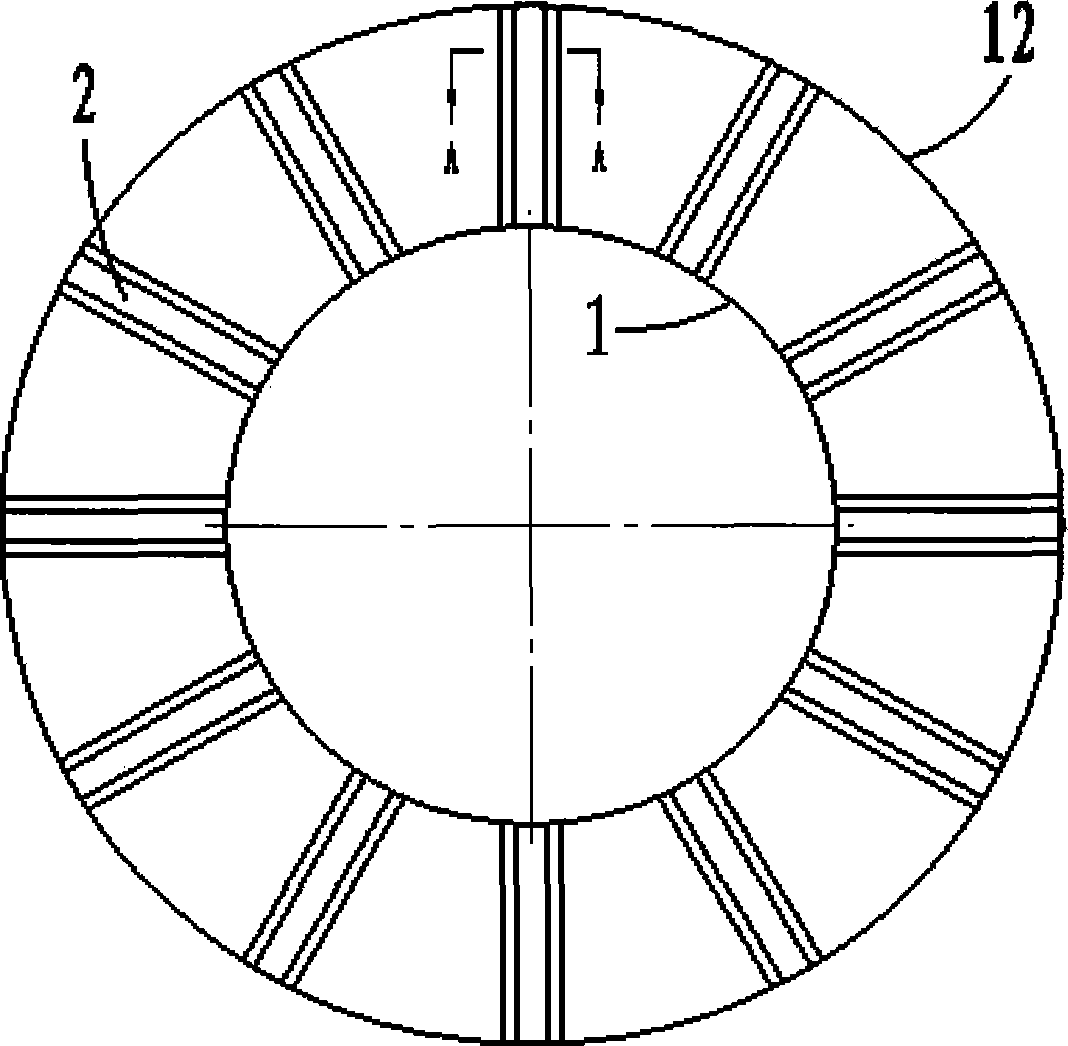

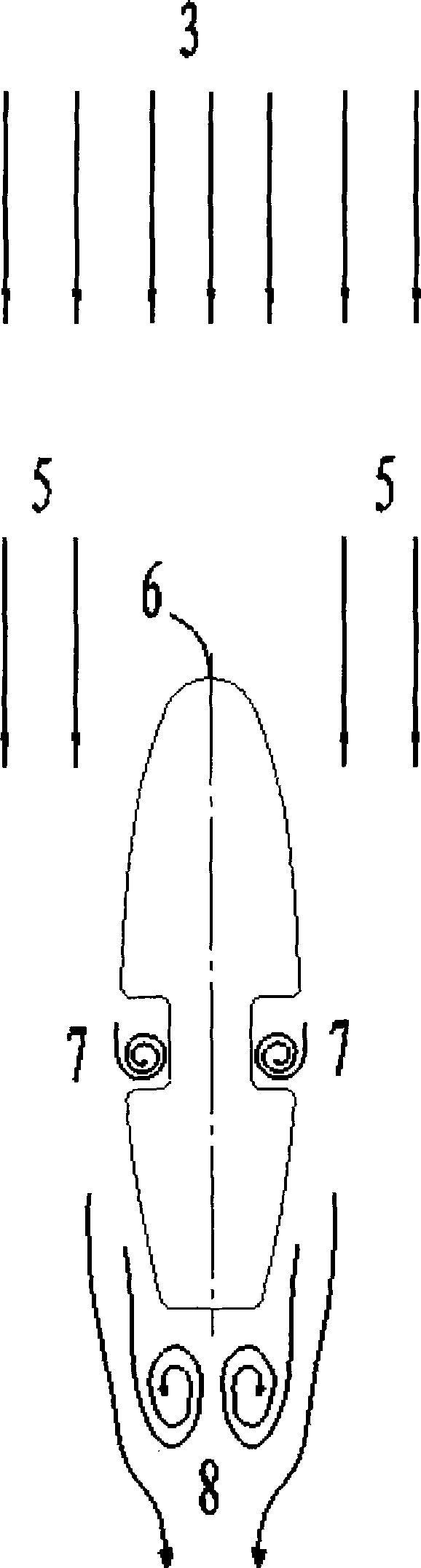

The invention provides a flame stabilizing device and method of an afterburner for a gas turbine engine. In the device, the original turbine rear frame supporting plate is replaced with the supporting plate with the cavities; and the device is characterized in that: the section of the supporting plate is in the shape of a wing with a suddenly expanded trailing edge and is provided with the cavities. The aim of stabilizing flame is fulfilled through a low-speed backflow region formed by flowing gas flow through the cavities of the supporting plate and the suddenly expanded part of the trailing edge. The invention provides the turbine rear frame supporting plate (2) of the afterburner for the gas turbine engine; the afterburner comprises a case (12), a turbine rear frame inner wall (1) and a plurality of turbine rear frame supporting plates (2), wherein the turbine rear frame supporting plates (2) are connected with the case (12) and the turbine rear frame inner wall (1); and the turbine rear frame supporting plate (2) is characterized by being provided with the cavities (9).

Description

technical field [0001] The invention relates to a flame stabilizing device for an afterburner in a gas turbine engine with afterburner, and more specifically relates to a scheme for improving the flame stabilization characteristics of the afterburner. Background technique [0002] The afterburner has been an important component of fighter jet engines since its invention. It adopts a direct-flow organization combustion scheme to greatly increase engine thrust in a short period of time. Traditional afterburners usually arrange V-shaped flame stabilizers in the flow field, and use high-speed airflow to bypass the recirculation zone formed by the blunt body structure to stabilize the flame and tissue combustion. However, the traditional blunt body stabilizer brings flow passage blockage and total pressure loss while stabilizing the flame, and its large structural size additionally increases the overall weight of the engine. Especially in the non-afterburning state, the addition...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F23R3/60F23R3/18

Inventor 金捷吴迪季鹤鸣刘雯佳杜刚柳阳刘玉英岳明王慧汝谭杰

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com