Pod-type vortex-induced vibration suppression device

A vortex-induced vibration and suppression device technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of reducing production costs, weakening hydrodynamic loads, etc., and achieve the effects of reducing production costs, weakening hydrodynamic loads, and solving vortex-induced vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

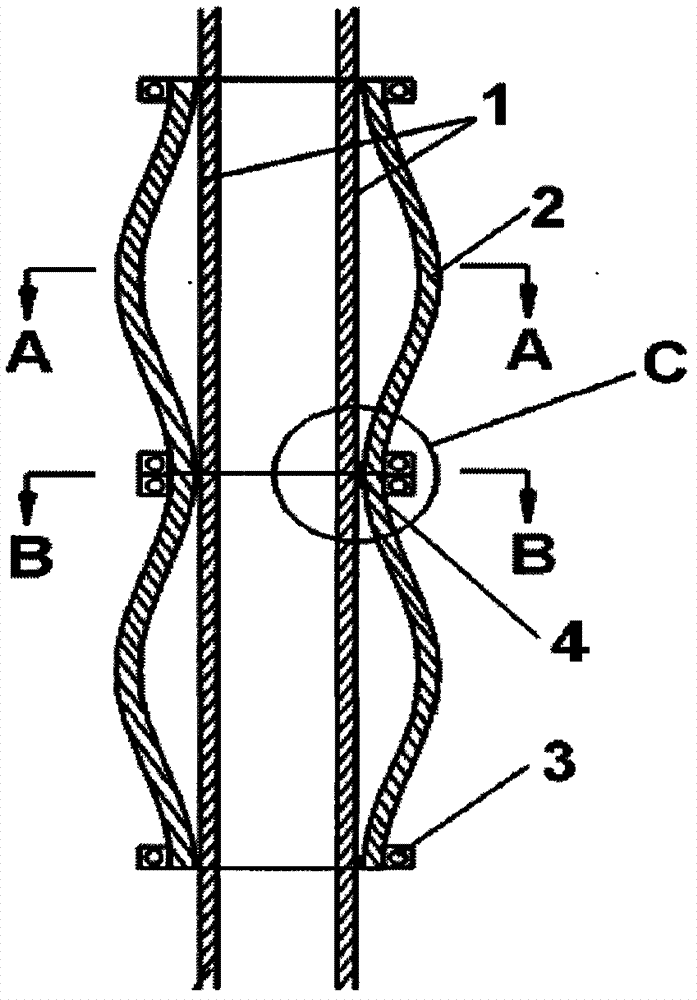

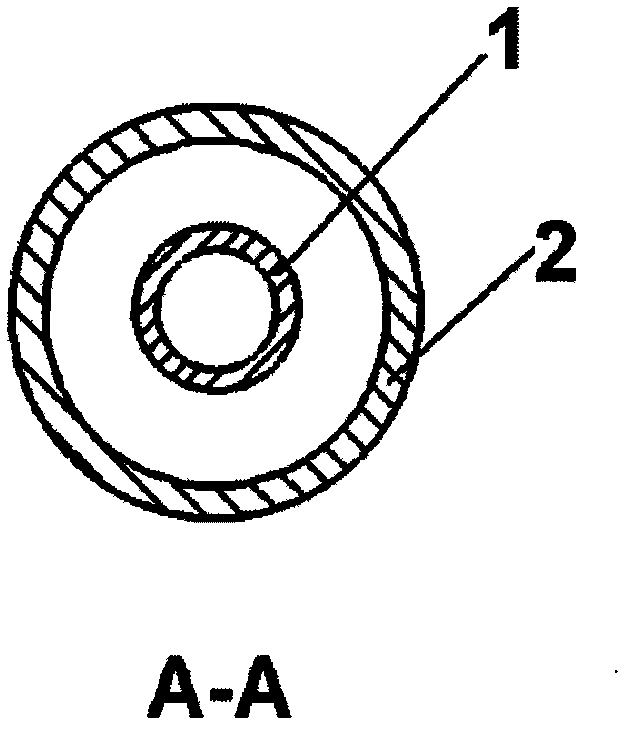

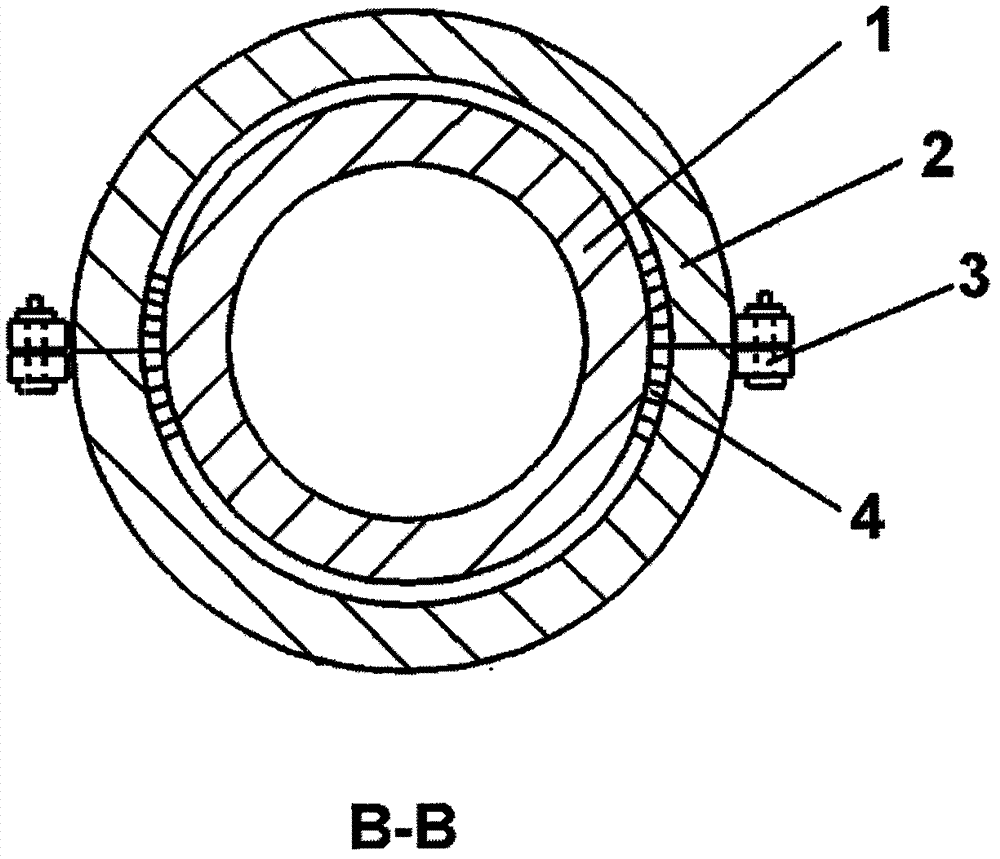

[0020] Such as Figure 1-Figure 4 As shown, the present invention includes: several sections of housing 2 with a circular cross-section, the housing 2 is fastened on the outer thin layer of the pipe 1 as the middle body part, and along the axial direction of the pipe 1, the thin layer is a simple harmonic type Change, the cross section is circular. The smallest diameter is called the trough (the diameter is slightly larger than the diameter of the pipe 1), and the largest diameter is called the peak; the radial difference between the smallest diameter position and the largest diameter position is called the wave height, and the axis between two adjacent smallest diameter positions The distance to the wavelength is the wavelength; the ratio of the wave height to the wavelength is called the wave steepness intensity, and the ratio of the wave height to the wavelength of the simple harmonic is greater than 0.05.

[0021] The outer surface of the shell 2 along the span direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com