Vehicle Pneumatic Tires

A technology for pneumatic tires and vehicles, applied to the reinforcement layer of pneumatic tires, vehicle components, special tires, etc., to achieve high run-flat performance and reduce the risk of carcass damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

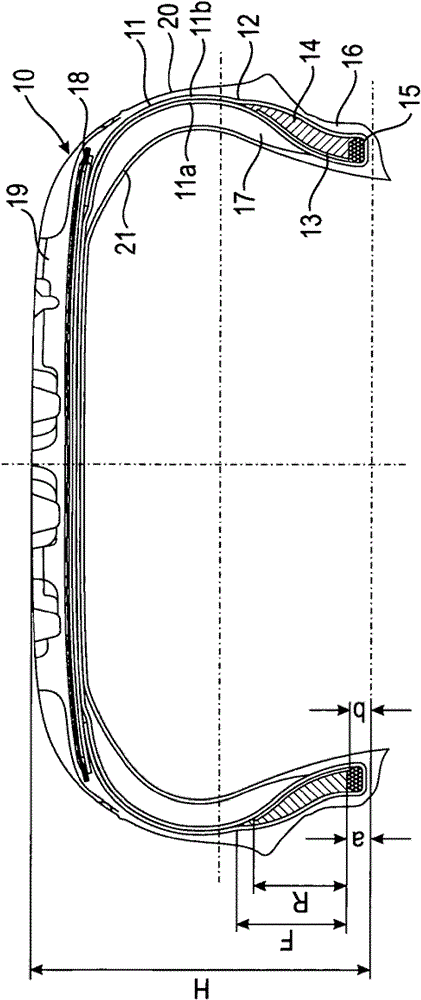

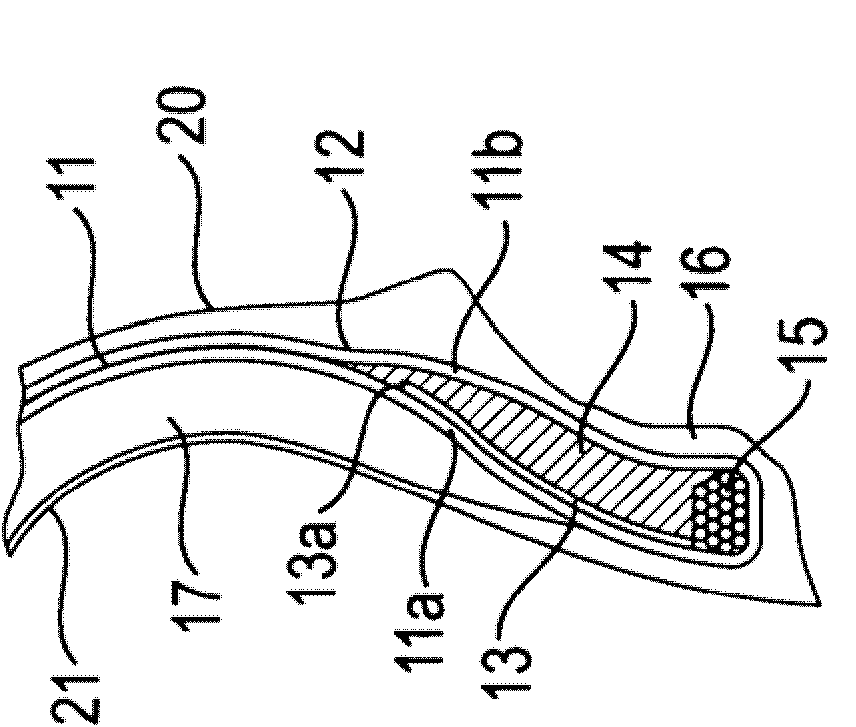

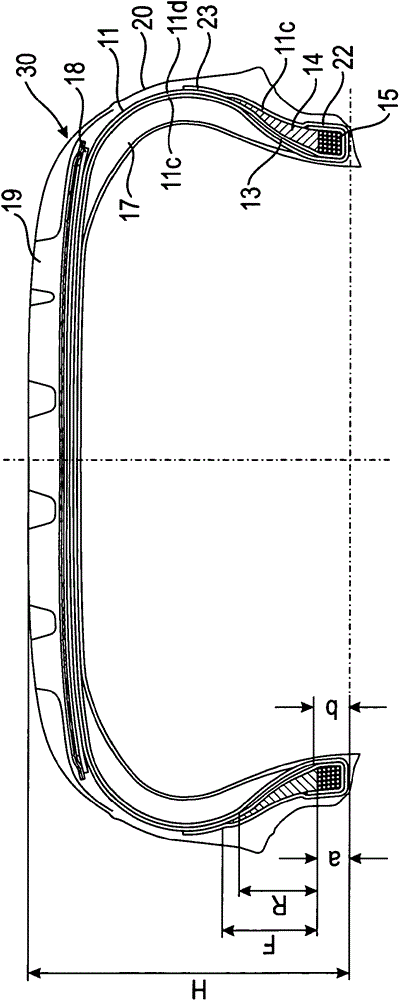

[0018] refer to figure 1 and 2 A pneumatic tire 10 according to the present invention includes a tread strip 19 and a pair of sidewalls 20 connected to the tread strip 19 . The carcass 11 is associated with two bead cores 15 arranged in the bead portion of the tire 10 . as available from figure 2 As seen, the carcass 11 is rolled up around the bead rings 15 . The carcass 11 thus comprises two parts, namely a part 11 a in the bead part and a part 11 b in the area of the sidewall 20 . In the bead portion of the tire 10 , the inner carcass portion 11 a and the outer carcass portion 11 b are separated by a bead core 15 and a bead filler 14 . The carcass portions 11 a and 11 b are joined together at a ply joint 12 . In the region of the side walls 20, the carcass parts 11a and 11b are directly connected to each other. The outer carcass portion 11 b extends to a belt structure 18 arranged between the carcass 11 and the tread strip 19 . Typically, the belt structure 18 comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com