Sample rack delivery system and biochemical analyzer

A transmission system and sample rack technology, which is applied in the field of sample rack transmission system, can solve the problems that affect the accuracy of test results, low priority, and cannot meet the high priority requirements of automatic retesting, and achieve the effect of changing the test priority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

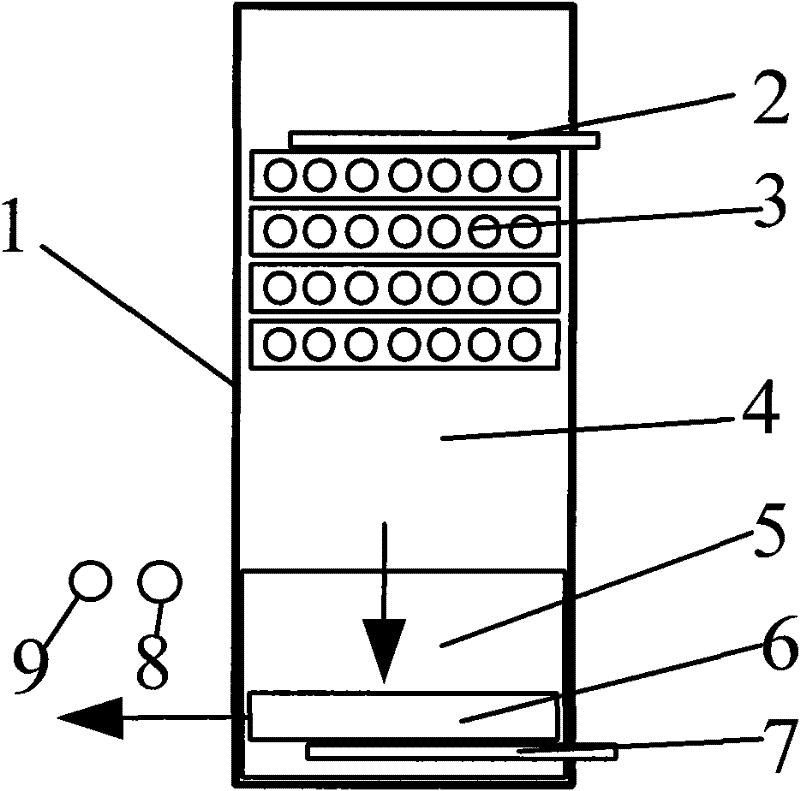

[0024] Please refer to figure 1 , the sample rack transfer system includes a sample carrying device 1 and a driving mechanism (not shown in the figure). The sample carrying device 1 is used to carry a sample rack, and includes a sample input area 4 , a sample outlet 6 , a sample rack pushing mechanism 2 and a sample rack pushing back mechanism 7 . The sample outlet 6 is located at the first end of the sample insertion area 4 . The sample rack propulsion mechanism 2 is coupled with the driving mechanism, and is used to push the sample rack 3 from the sample insertion area 4 to the direction of the sample outlet 6 driven by the driving mechanism, so that the sample rack 3 reaches the sample suction position for execution Aspirating operation, so the initial position of the sample rack propulsion mechanism 2 is set above the side of the sample insertion area 4, for example, the initial position of the sample rack advancement mechanism 2 is set at the side of the sample insertion...

Embodiment 2

[0027] like figure 1 As shown, on the basis of Embodiment 1, the sample rack transfer system can further include a priority change control key 9 as an emergency button, and can also include a run key 8, when the priority change control key is triggered (for example, pressed or rotated) or toggle), a trigger signal is generated, and the driving mechanism responds to the trigger signal and drives the sample rack pushback mechanism to move from the outside of the sample outlet to the direction of the sample insertion area. The running key 8 is used to control the driving mechanism to drive the sample rack propulsion mechanism 2 to move.

[0028] The emergency button is arranged on the sample rack transmission system. When the user needs to treat the emergency sample first, press the emergency button first, and the sample rack already in the sample insertion area will be moved back through the sample rack push-back mechanism, and back out of the emergency insertion area. Insertin...

Embodiment 3

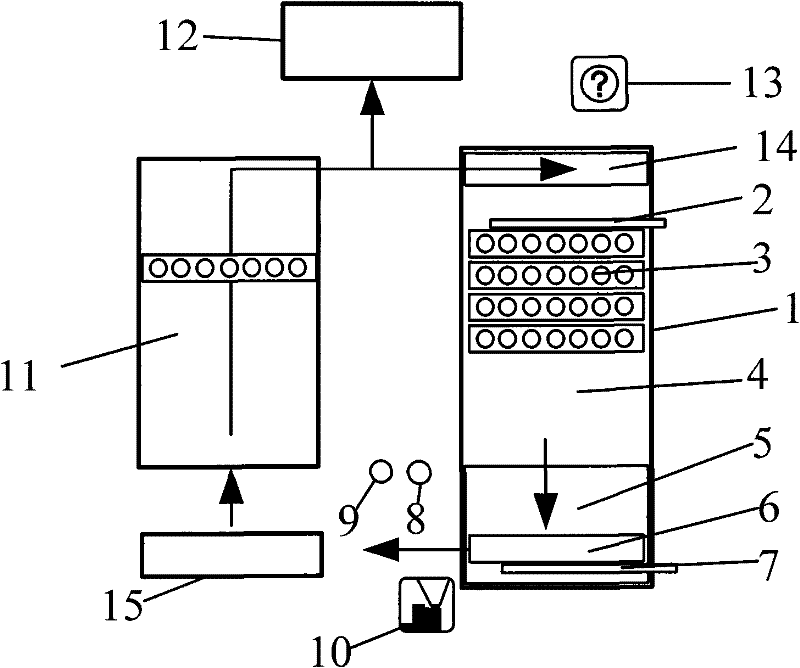

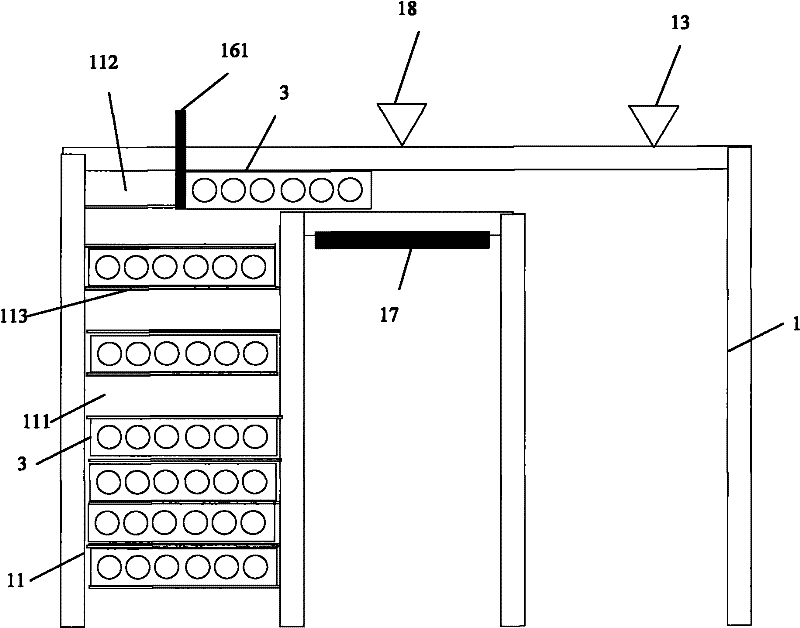

[0030] Please refer to Figure 2-4 . like figure 2 As shown, the sample rack delivery system includes a sample carrying device 1 , a driving mechanism (not shown in the figure), a sample retest buffer device 11 and a retest sample delivery device (not shown in the figure). The sample carrying device 1 is located upstream of the sample suction position 15, and the sample retest buffer device 11 is located downstream of the sample suction position 15. The sample retest buffer device 11 is used to store the sample racks that have been tested and are waiting for the test results, and the retest The sample delivery device is located downstream of the sample retest buffer device 11, and is coupled with the driving mechanism, and is used to transport the sample rack that has obtained the test result from the retest outlet to the sample rack that is located at the sample insertion port under the drive of the drive mechanism. The retest inlet at the second end of the zone or the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com