The leveling device of the operating platform of the railway catenary wire-stretching operation vehicle

A technology of working platform and leveling device, which is applied in the direction of lifting device, etc., and can solve problems such as being unable to stand stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

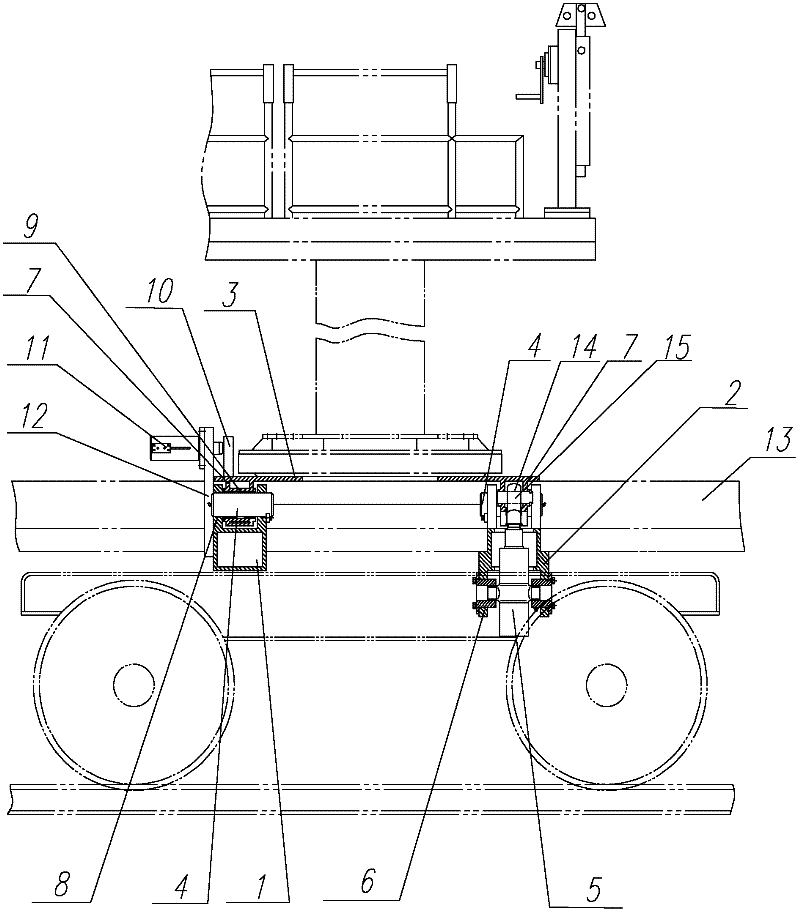

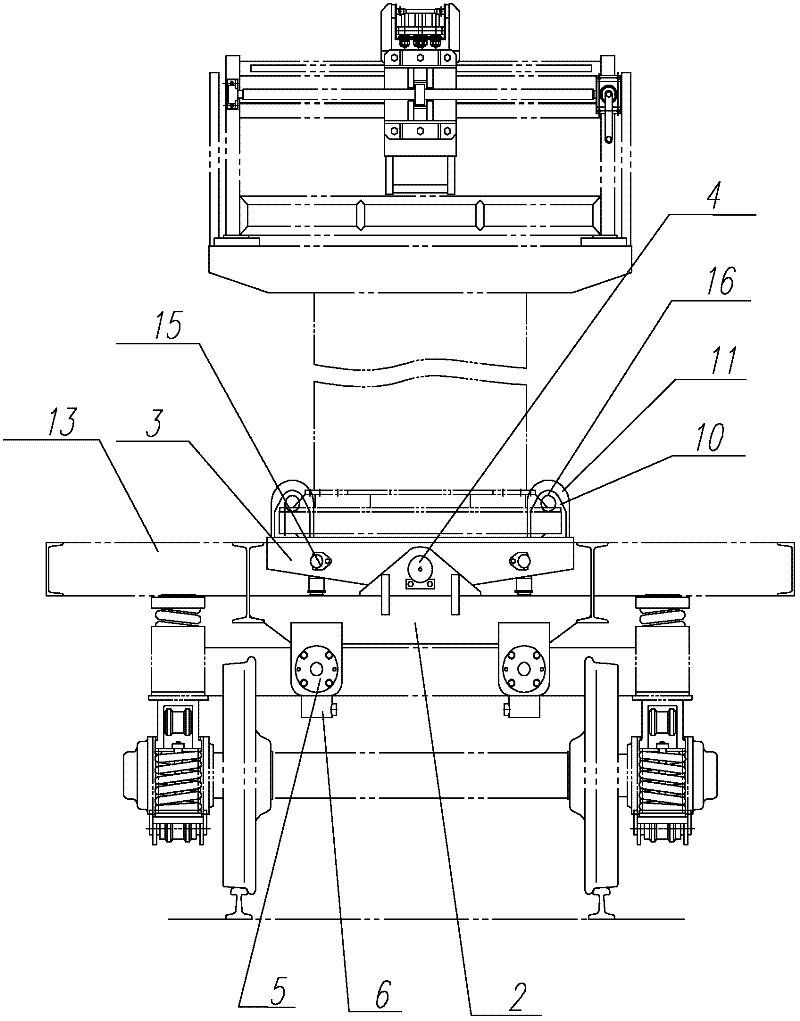

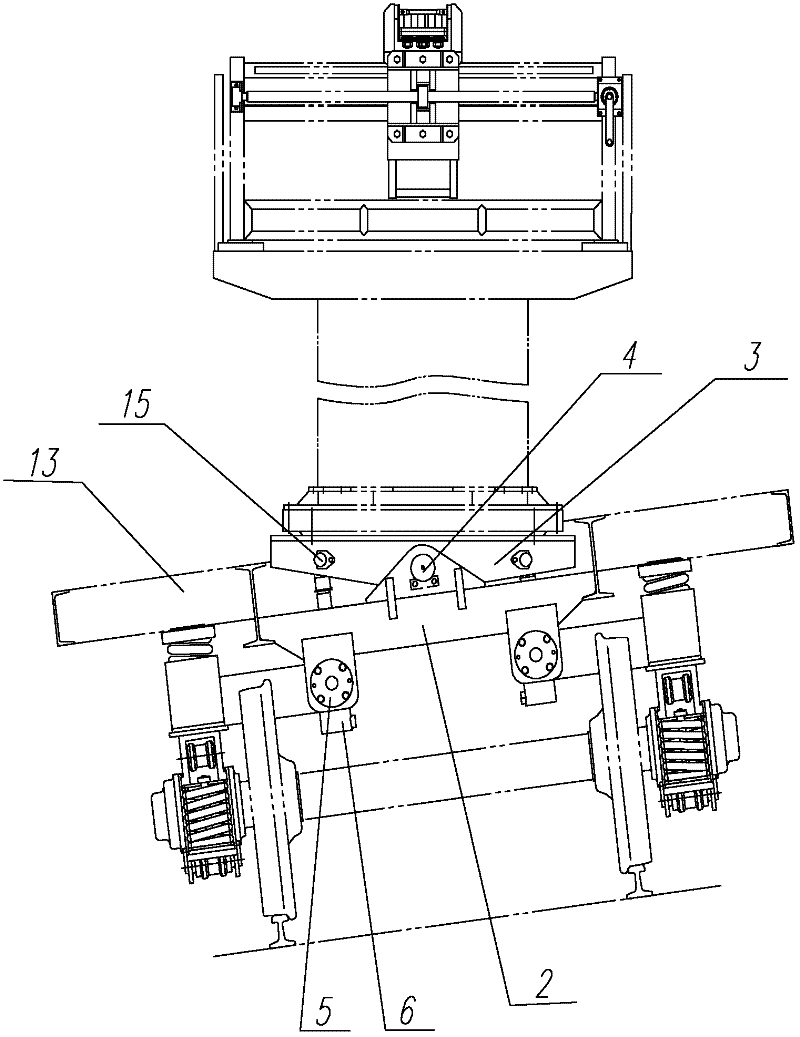

[0020] Attached below figure 1 , 2 , 3, 4, 5, 6 describe an embodiment of the present invention.

[0021] The leveling device of the operation platform of the railway catenary wire-stretching operation vehicle includes a leveling mechanism, a leveling hydraulic system and a leveling electrical control system. , the front seat beam 1 and the rear seat beam 2 are respectively welded and connected with the vehicle frame 13 as a whole, which is the basis of the whole leveling mechanism; Connection, both sides of the rear end of the lifting and rotating work platform base 3 are connected to the rear seat beam 2 through the rear rotating shaft 4, and the lifting and rotating working platform base 3 can rotate 9° left and right around the rotating shaft 4, specifically, the lifting and rotating working platform base 3 End bases 7 are formed on the lower end surfaces of the front and rear ends, and pin holes II9 corresponding to the pin holes I 8 on the front seat beam 1 and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com