Apparatus and method for friction stir welding

A friction stir and joining device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to achieve good friction stir welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

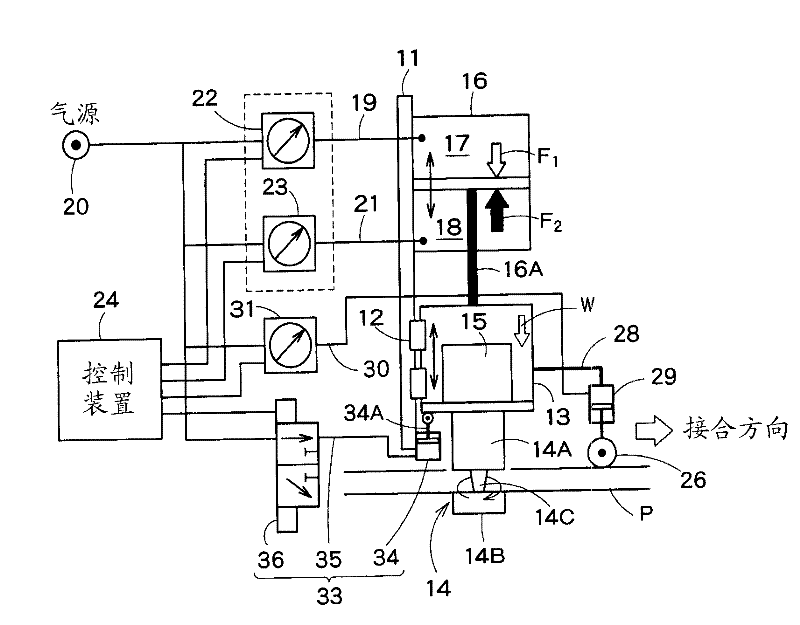

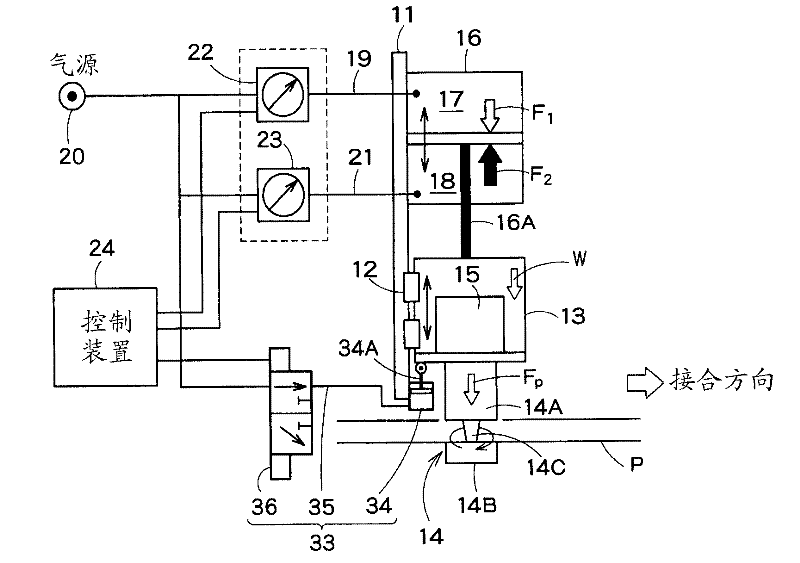

[0061] Hereinafter, a friction stir welding apparatus and its method as one embodiment of the present invention will be described with reference to the drawings.

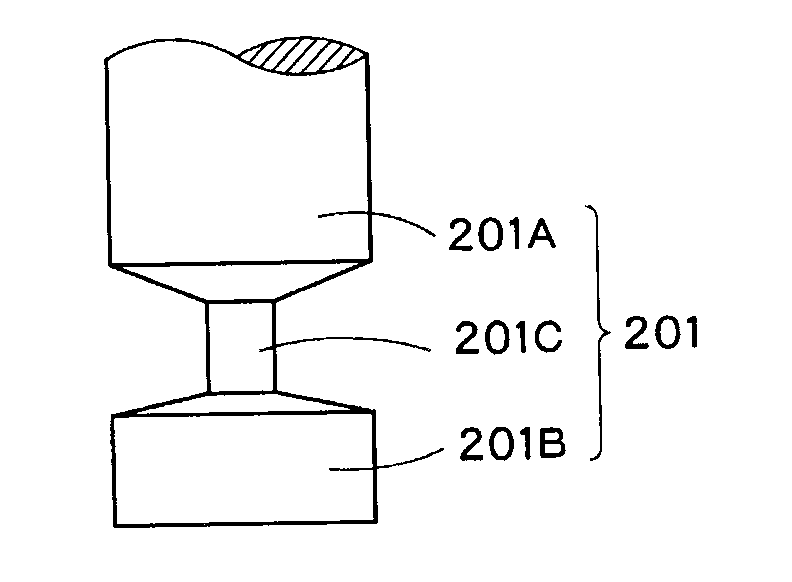

[0062] like figure 1 As shown, the friction stir welding apparatus 10 of this embodiment has the welding head 13 which is attached to the head support part 11 of the apparatus main body so that it can move linearly up and down via the linear guide 12. A bonding tool 14 that contacts the member P to be bonded during the bonding operation is rotatably attached to the bonding head 13 , and the bonding tool 14 is driven by a tool rotation drive motor (rotation drive unit) 15 provided on the bonding head 13 . rotate.

[0063] An air cylinder (head drive unit) 16 for driving the head is fixedly provided on the head supporting portion 11 , and the bonding head 13 is attached to a piston rod 16A of the air cylinder 16 . In addition, instead of the air cylinder 16, another fluid pressure cylinder such as a hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com