Friction stir welding method

A friction stir and joining method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve good friction stir welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

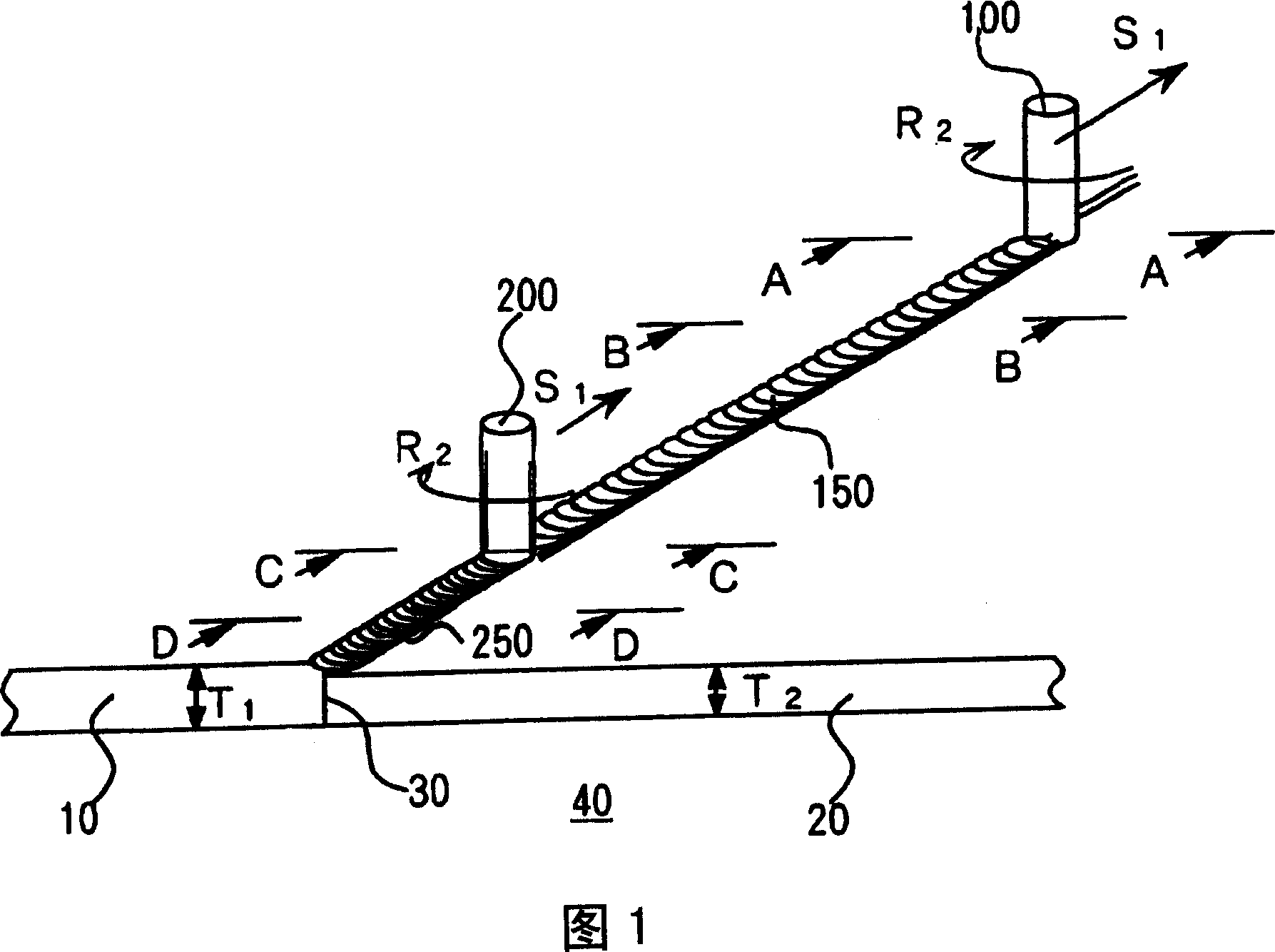

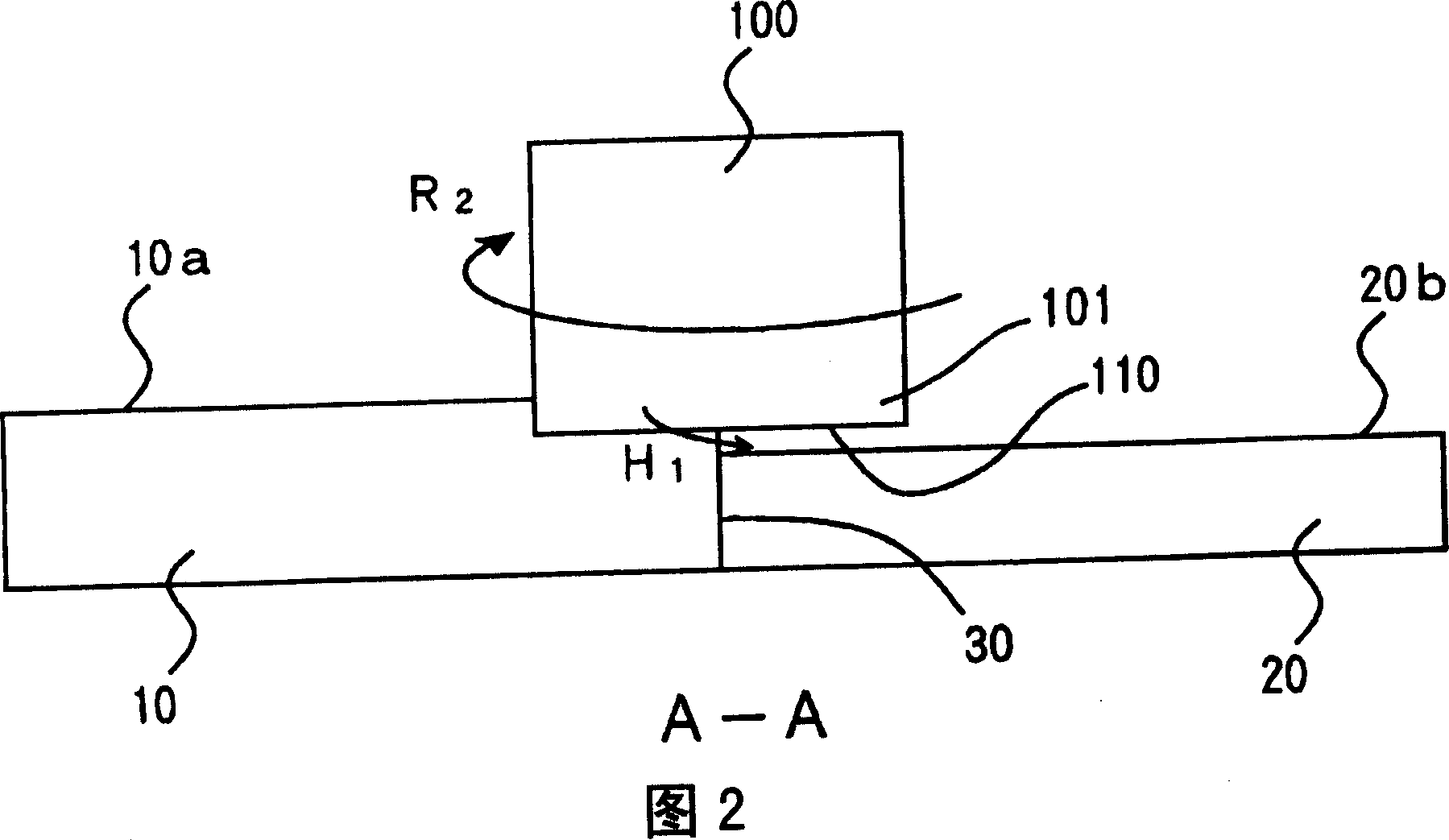

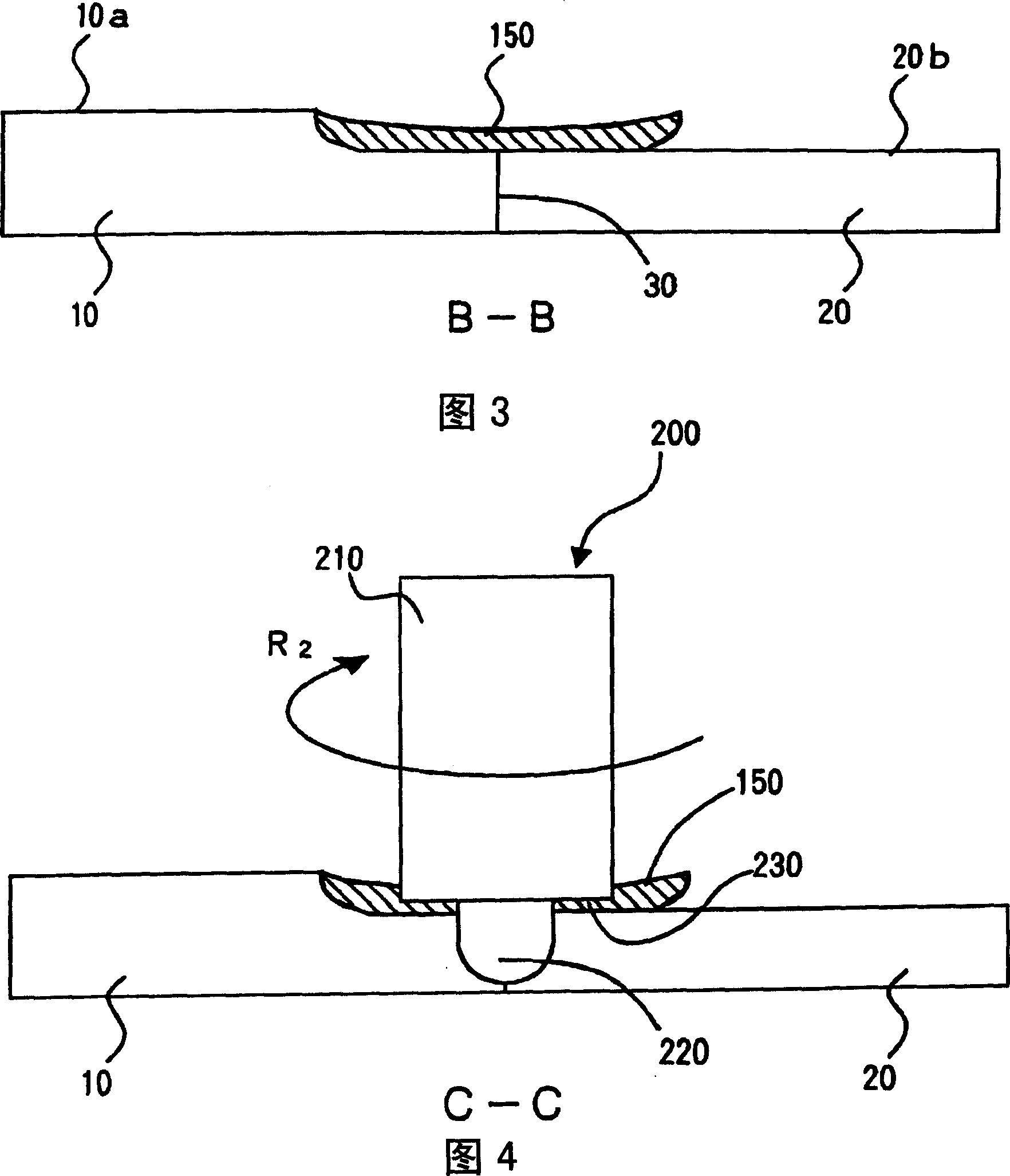

[0039] An embodiment of the friction stir welding method of the present invention will be described with reference to FIGS. 1 to 6 . The joining conditions of the first member 10 and the second member 20 are the same as those described with reference to FIGS. 14 and 15 .

[0040] That is, it is a method of performing friction stir welding on the abutment portion 30, wherein the abutment portion 30 will have a thickness dimension T 1 of the first component 10 with a thickness dimension T less than 1 The thickness dimension T 2 The second part 20 is docked. The first component and the second component are aluminum alloy. The second part 20 with a smaller thickness is located on the right-hand side of the first part in FIGS. 1 to 4 .

[0041] The friction stir welding method of the present invention includes two steps.

[0042] In the first step, before the friction stir welding of the mating portion 30 , the convex portion replacement portion 150 is formed on the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com