Rubber material for fabricating vibration-proof rubber assembly used for fan in commercial air-conditioner

A rubber material and rubber technology are applied in the field of rubber materials for preparing anti-vibration rubber components for air-conditioning fans, and can solve the problems of corrosion of metal objects, short service life, and special working conditions of air-conditioning fans are not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

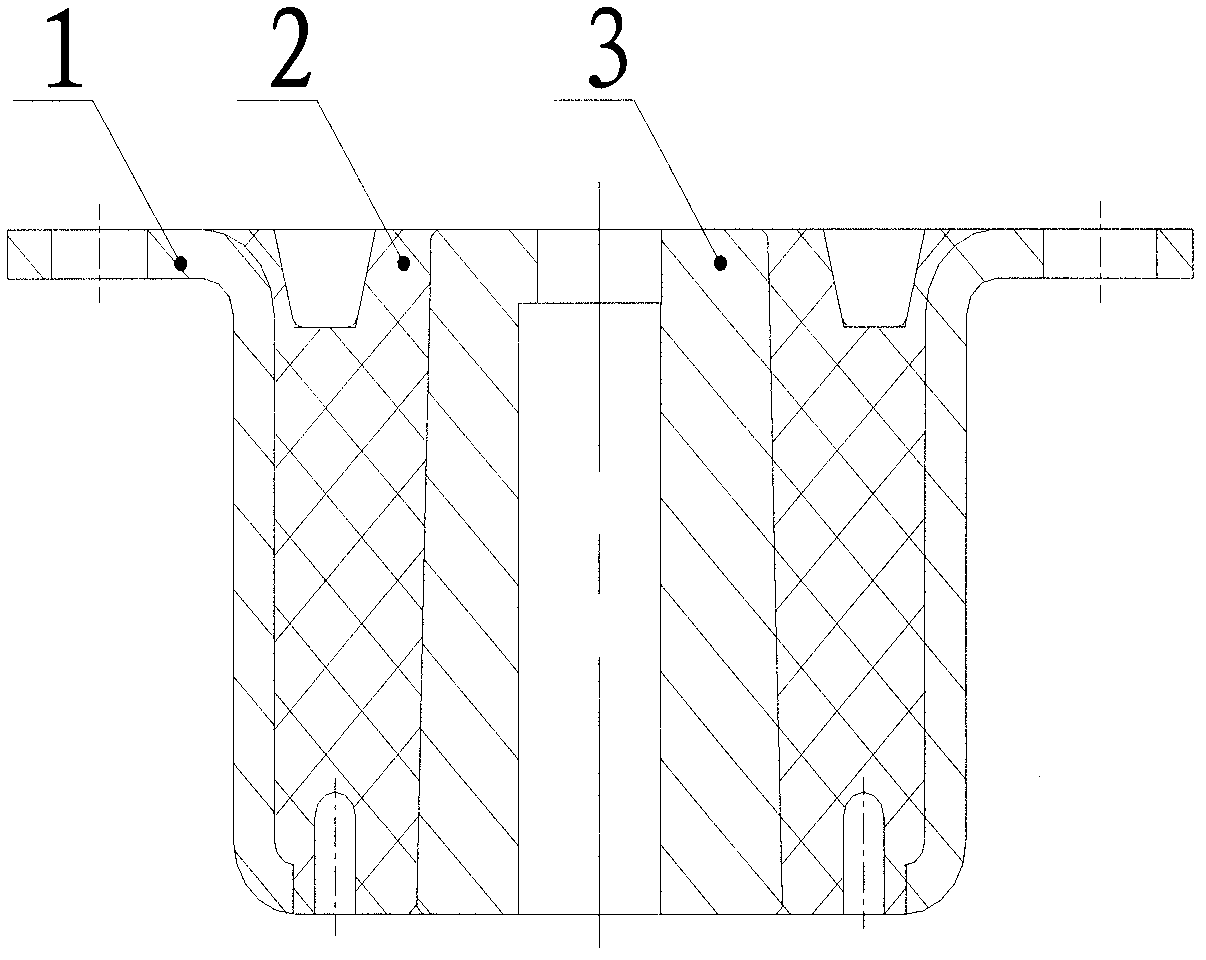

Image

Examples

Embodiment 1

[0049] In the present embodiment, the raw material of the rubber material for preparing anti-vibration rubber constitutes by mass percentage:

[0050]

[0051]

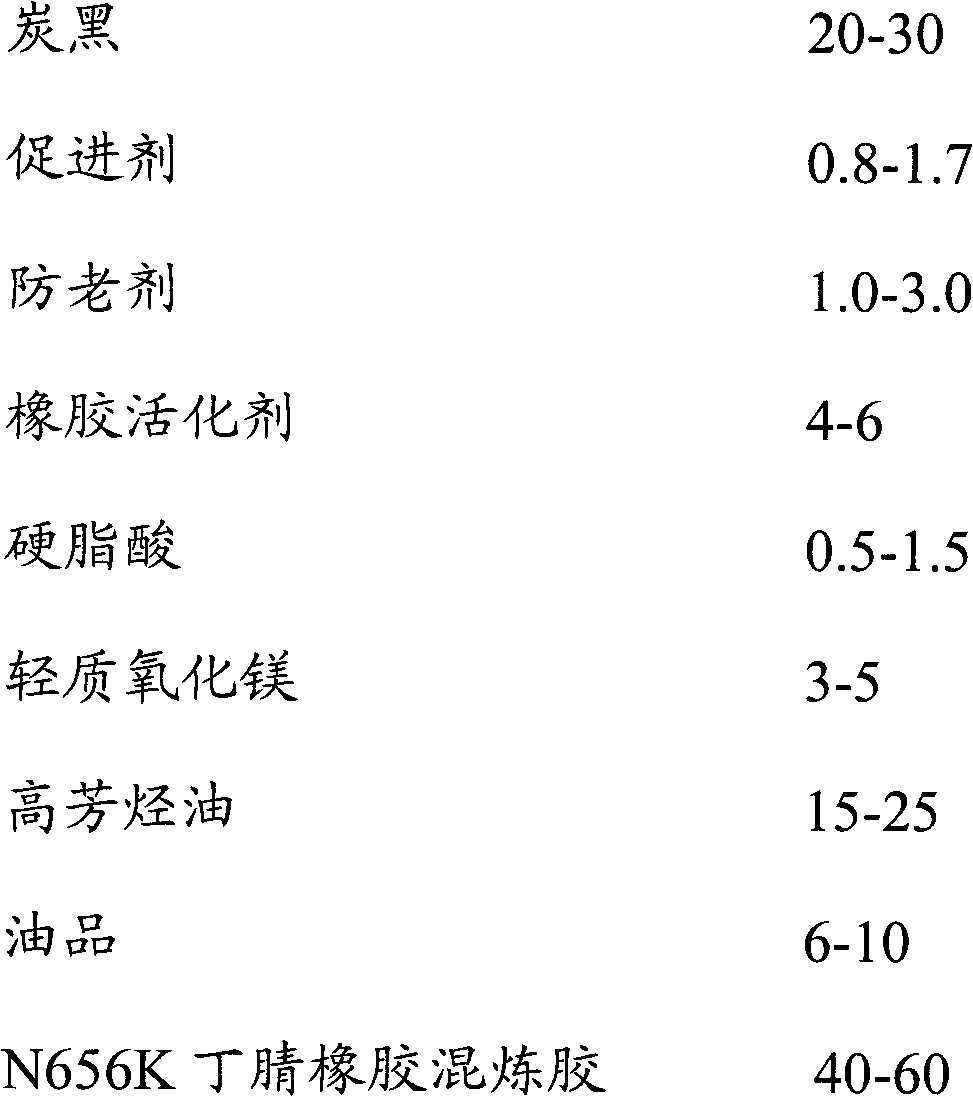

[0052] Described N656K acrylonitrile-butadiene rubber compound rubber, its raw material constitutes by mass parts:

[0053]

Embodiment 2

[0055] In the present embodiment, the raw material of the rubber material for preparing anti-vibration rubber constitutes by mass percentage:

[0056]

[0057]

[0058] Described N656K acrylonitrile-butadiene rubber compound rubber, its raw material constitutes by mass parts:

[0059]

Embodiment 3

[0061] In the present embodiment, the raw material of the rubber material for preparing anti-vibration rubber constitutes by mass percentage:

[0062]

[0063] Described N656K acrylonitrile-butadiene rubber compound rubber, its raw material constitutes by mass parts:

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap