Pneumatic tire

A technology for pneumatic tires and tread rubber, which is applied to the reinforcement layers, tire parts, wheels and other directions of pneumatic tires, can solve the problems of not improving the wet braking performance and not being disclosed, and achieves improving the wet braking performance and ensuring the control The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

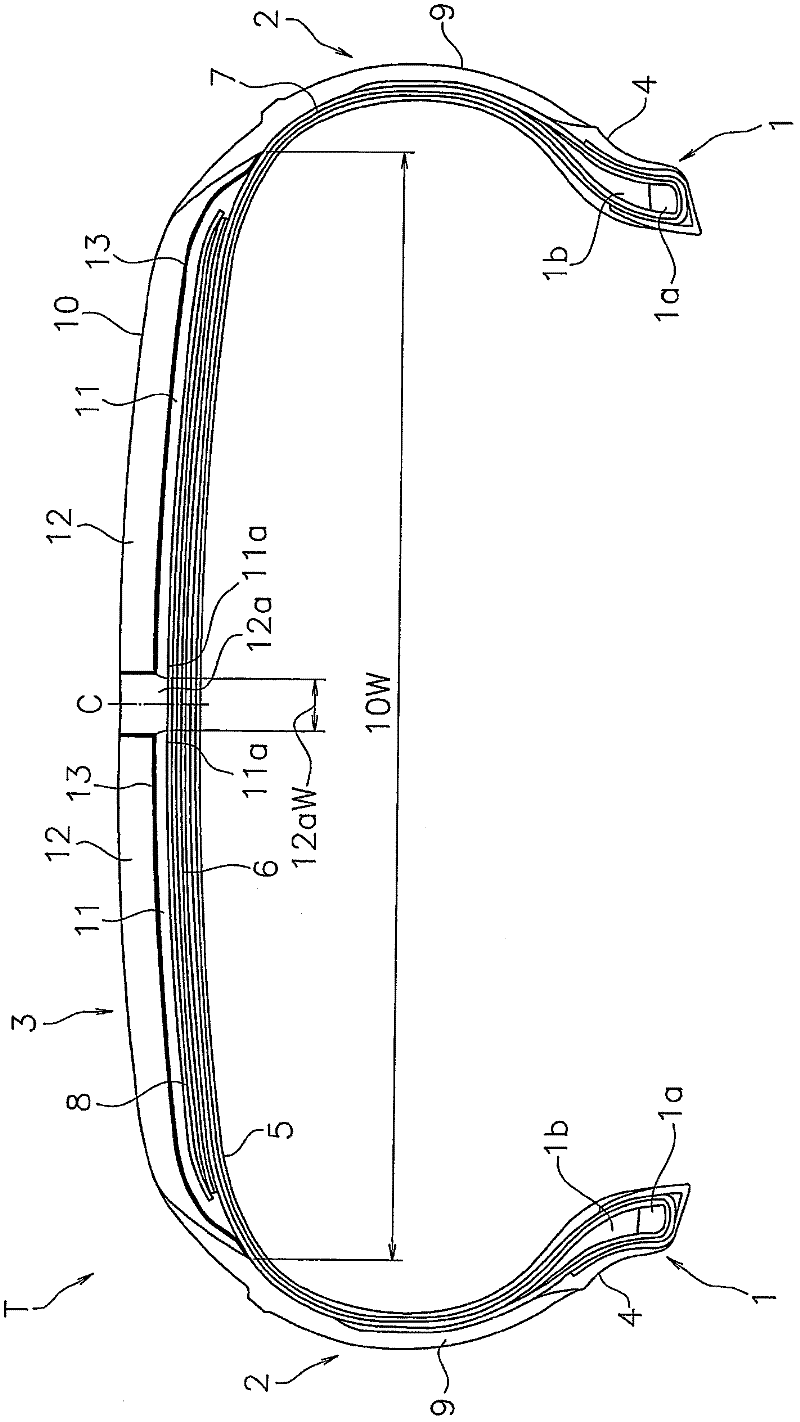

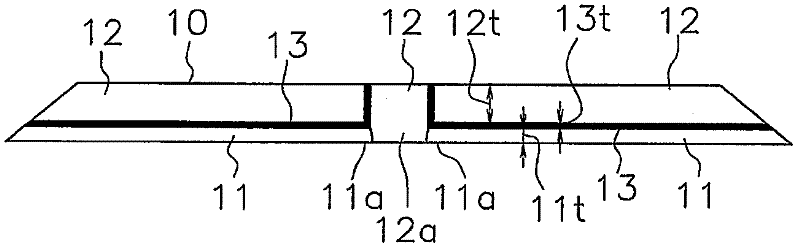

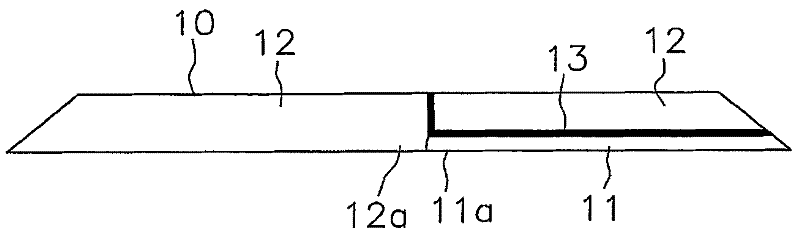

[0053] (1) In the above-mentioned embodiment, the example in which the buffer rubber 13 is provided on both sides of the tread width direction is shown, but as image 3 As shown, it may be provided only on one side in the tread width direction. Even in this case, since the top rubber 12 has a penetrating portion 12a penetrating from the ground contact surface to the bottom surface of the tread rubber 10 in the central region, the effect of maintaining the tire transverse shear rigidity as described above can be obtained. Additionally, in this embodiment, with figure 2 It is also possible to set the base rubber 11 on the other side in the tread width direction in the same way, and then with the following Figure 4 Similarly, the buffer rubber 13 may be provided on the inner periphery of the base rubber 11 .

[0054] In this configuration, it is preferable that the shoulder area on the side where the cushion rubber 13 is provided ( image 3 The right shoulder area of the t...

Embodiment

[0058] Next, examples that specifically show the configuration and effects of the present invention will be described. The tires used for the evaluation are as follows: the tire model is 205 / 55R16, the air pressure is 220 kPa, and the rim model is 16×6.5-JJ. Each evaluation item was evaluated as follows.

[0059] (1) Wet braking performance

[0060] The vehicle was driven on a wet road, and the braking distance when the driving speed decreased from 100 km / h to 0 km / h was measured, and evaluated using an index when the result of Comparative Example 1 was set to 100. The smaller the value, the shorter the braking distance, indicating better wet performance.

[0061] (2) wear performance

[0062] After running for 8000 km, the difference in height between the step-in side and the kick-out side of the blocks provided in the shoulder region (the amount of zigzag wear) was measured and evaluated using the index when the result of Comparative Example 1 was set to 100. The smaller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com