Method for rapidly repairing spacecraft valve sealing structure

A valve sealing and repair method technology, applied in the field of aerospace propulsion valves, can solve the problems of economic loss, difficulty in prevention and control, and high cost of aerospace products, and achieve the effects of restoring sealing performance, convenient and fast operation, and eliminating penetrating scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

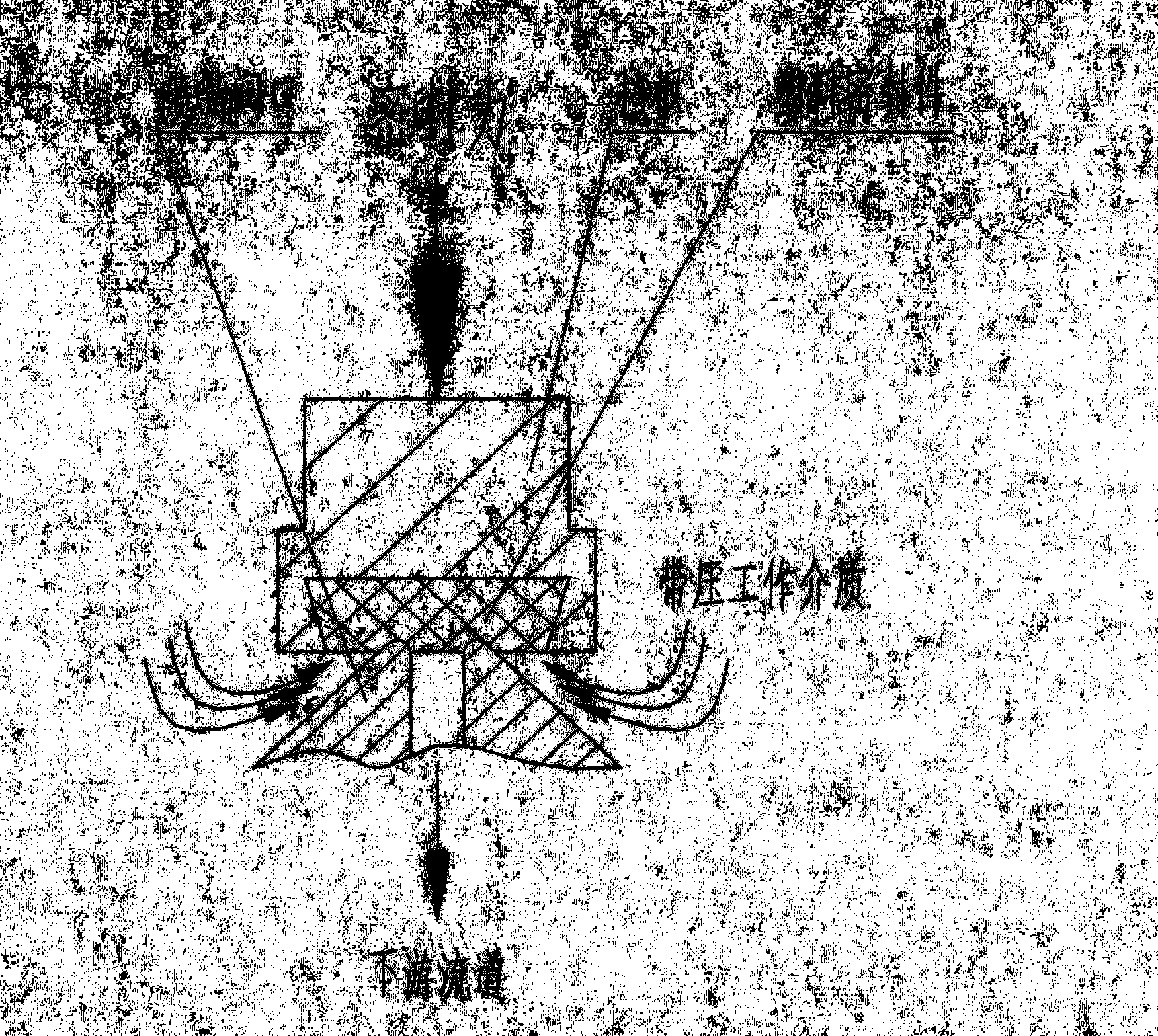

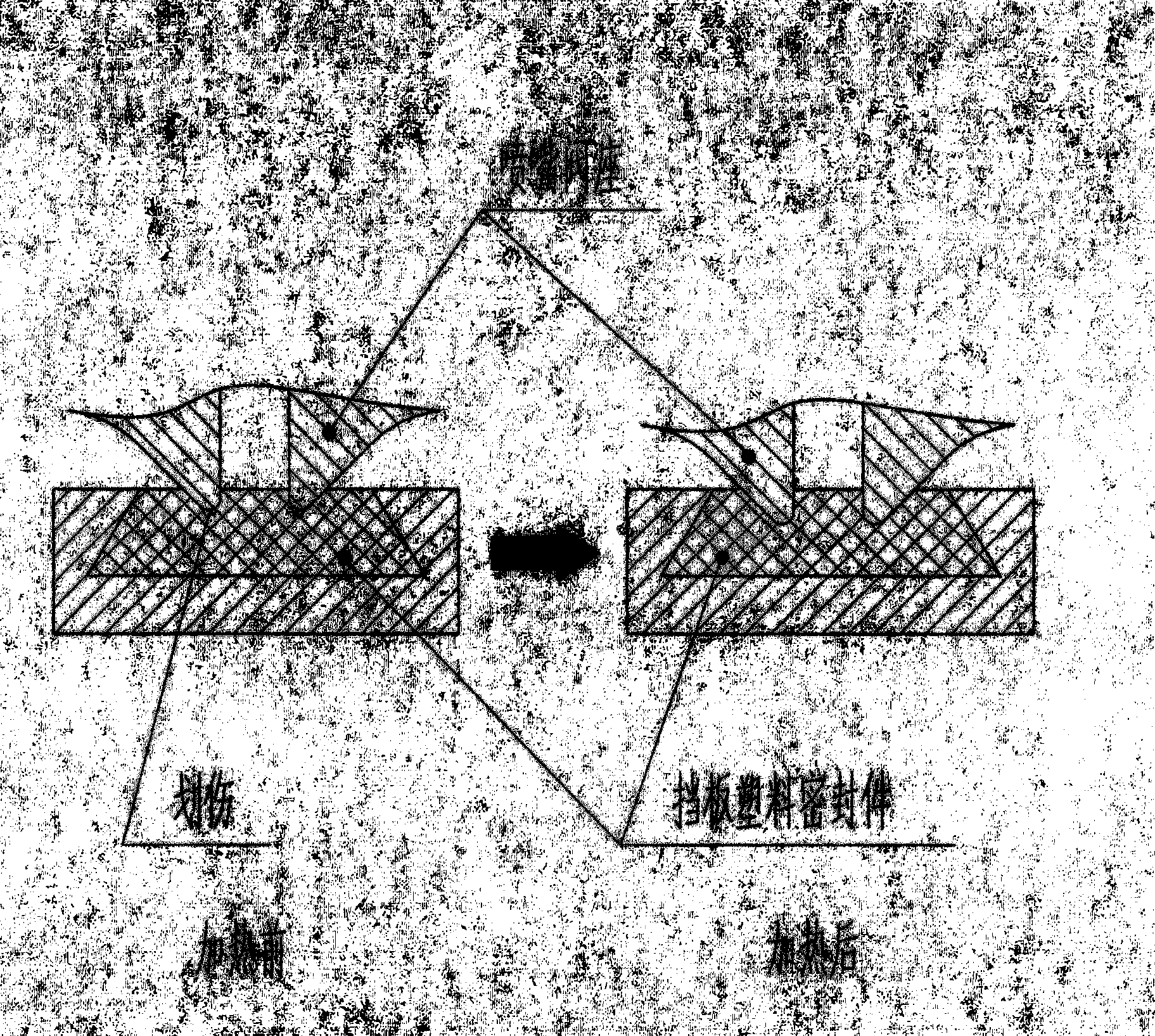

[0028] Such as figure 1 As shown, the typical sealing structure of aerospace valves is a nozzle-baffle structure, including nozzle valve ports, baffles and plastic seals. The plastic seal is inlaid on the metal baffle, and forms a pair of sealing pairs with the nozzle valve port. Under the action of the sealing force, the plastic sealing surface is deformed, and it fits closely with the nozzle valve port, blocking all the tiny flow channels, making the work The medium cannot flow, and a reliable seal is achieved. When scratches appear on the plastic sealing surface, there will be gaps that cannot be bridged on the fitting surface, resulting in internal leakage of the valve.

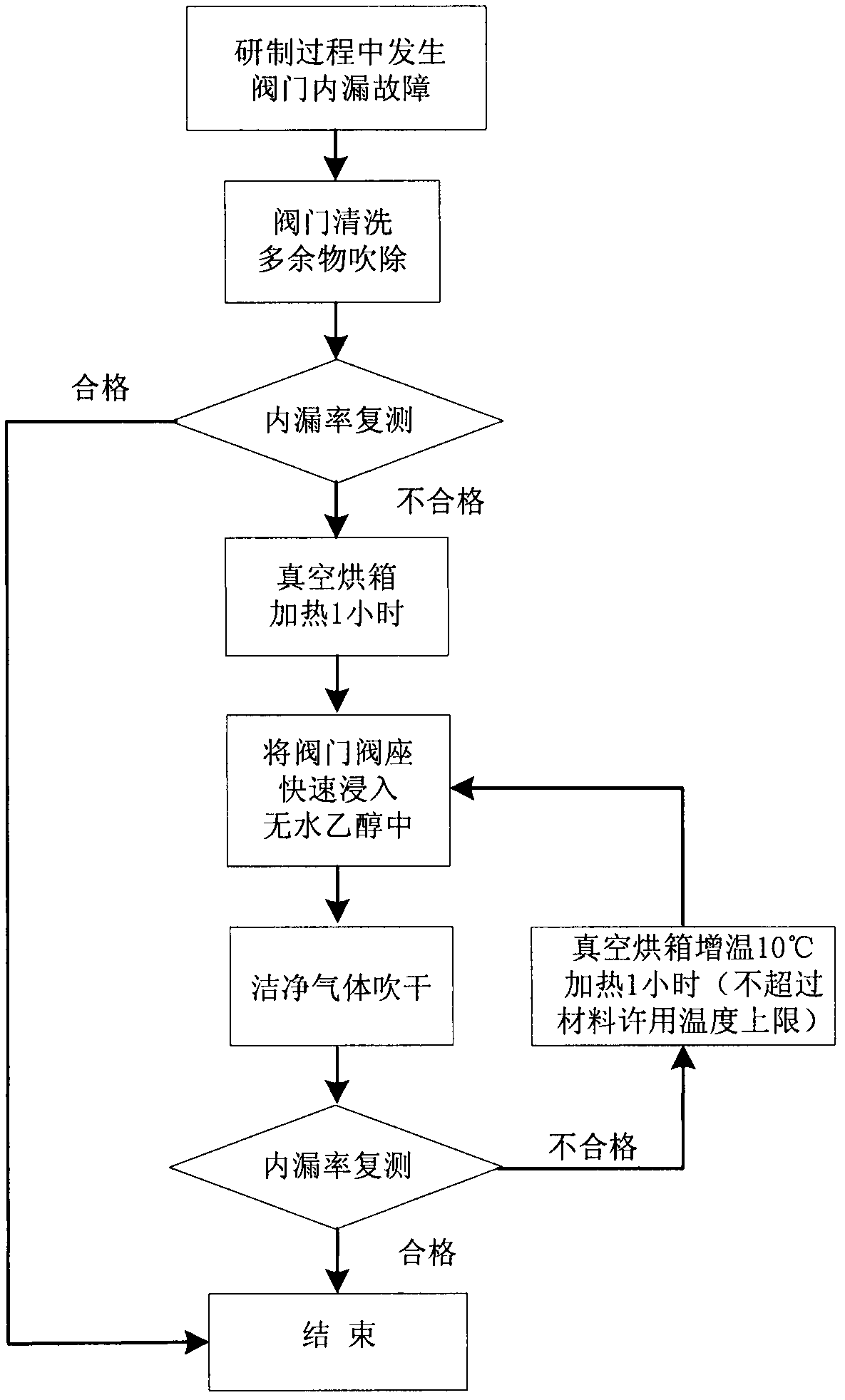

[0029] Such as figure 2 As shown, the present invention provides a quick repair method for the sealing structure of aerospace valves, the steps are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com