Recycling type smoke control method of tunnel

A technology for smoke prevention and tunneling, which is applied in mine/tunnel ventilation, dust prevention, earthwork drilling and mining, etc. It can solve the problems of large capacity and poor effect of pressurized blower, and achieves simple structure, excellent performance and remarkable smoke prevention effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

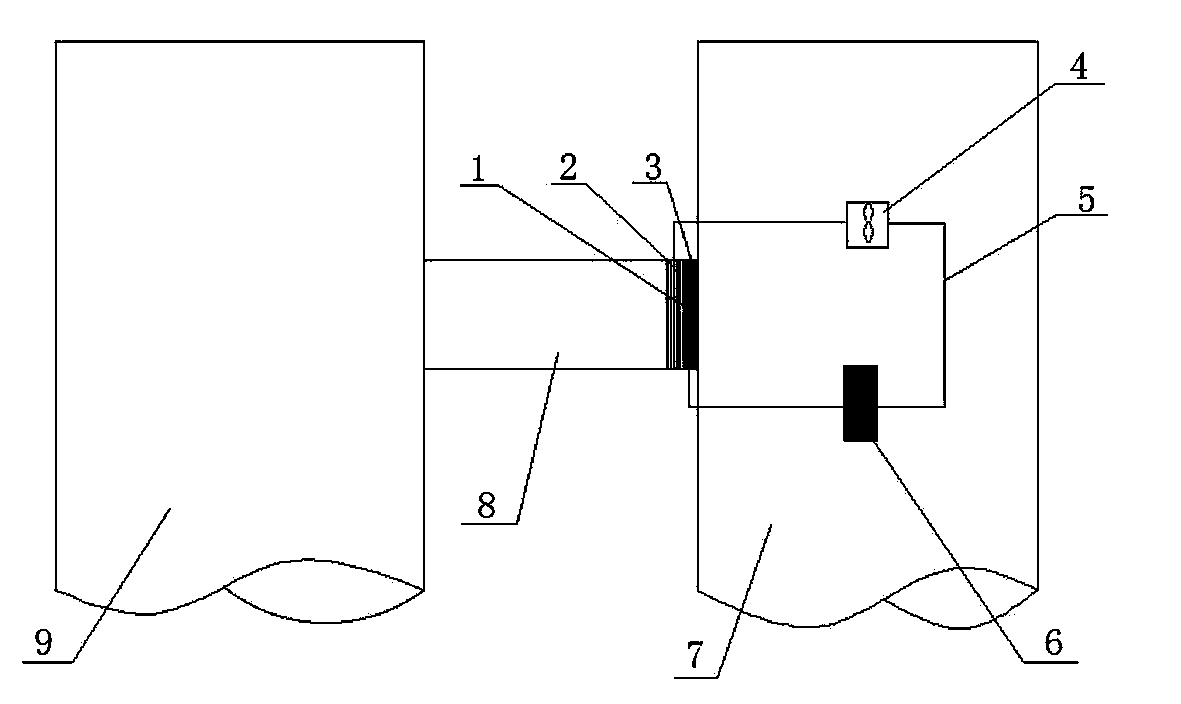

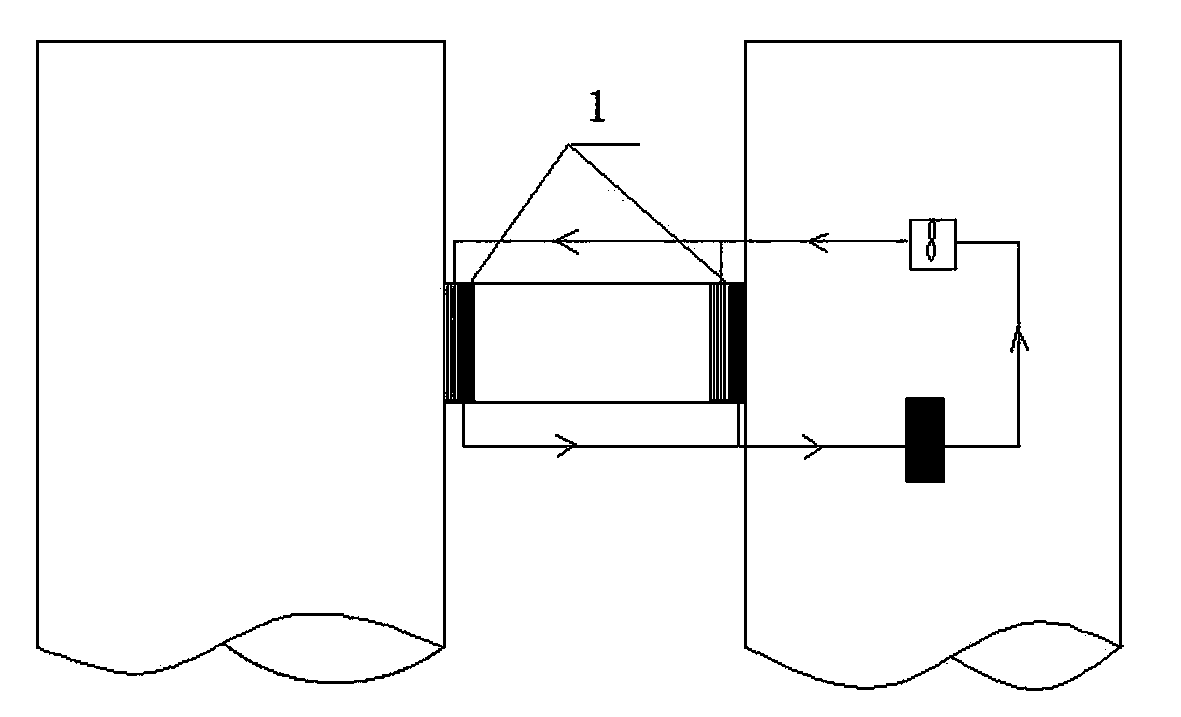

[0016] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0017] like figure 1 The marks 1-9 represent the circulating air curtain machine 1, the air supply slit 2, the return air outlet 3, the fan 4, the air duct 5, the dust collector 6, the safe evacuation channel 7, the communication channel 8, and the main tunnel 9.

[0018] like figure 1 Shown is a schematic structural diagram of the present invention. The equipment required for a recyclable tunnel smoke prevention method related to the present invention mainly includes a circulating air curtain machine 1 , an air duct 5 , a dust collector 6 and a fan 4 .

[0019] The concrete steps of this method are as follows:

[0020] ① Install a circulating air curtain machine 1 at the junction of the communication channel 8 and the safe evacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com