Titanium blades of compressor repaired by cold pressing

A technology of compressor blades and blades, which is applied in the directions of blade support elements, mechanical equipment, engine elements, etc., can solve problems such as the reduction of blade strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

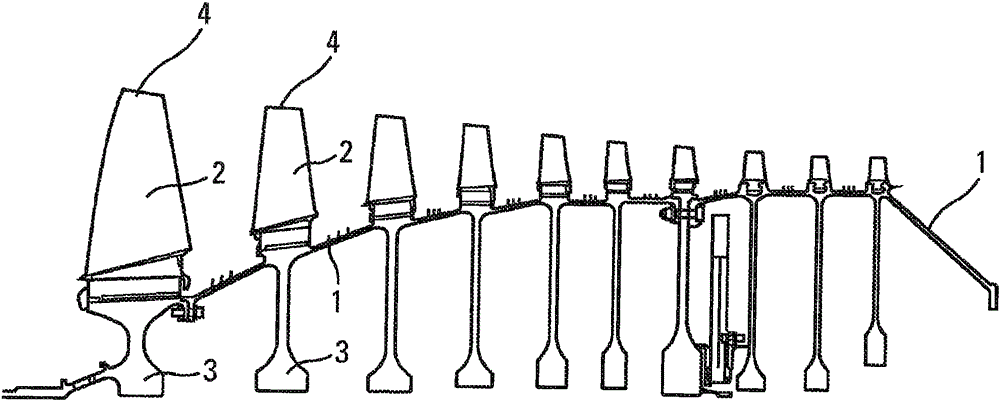

[0021] refer to figure 1 , figure 1 A cross-section of a rotor 1 of a turbomachine compressor is shown, including blades 2 mounted on the rotor 1 and a compressor disk 3 inside the rotor 1 facing the blades 2 . Each blade 2 has a root secured to the rotor 1 using techniques known to those skilled in the art, and the blades extend as far as the tip, or tip 4, to which the repair method that forms the subject of the present invention is directed.

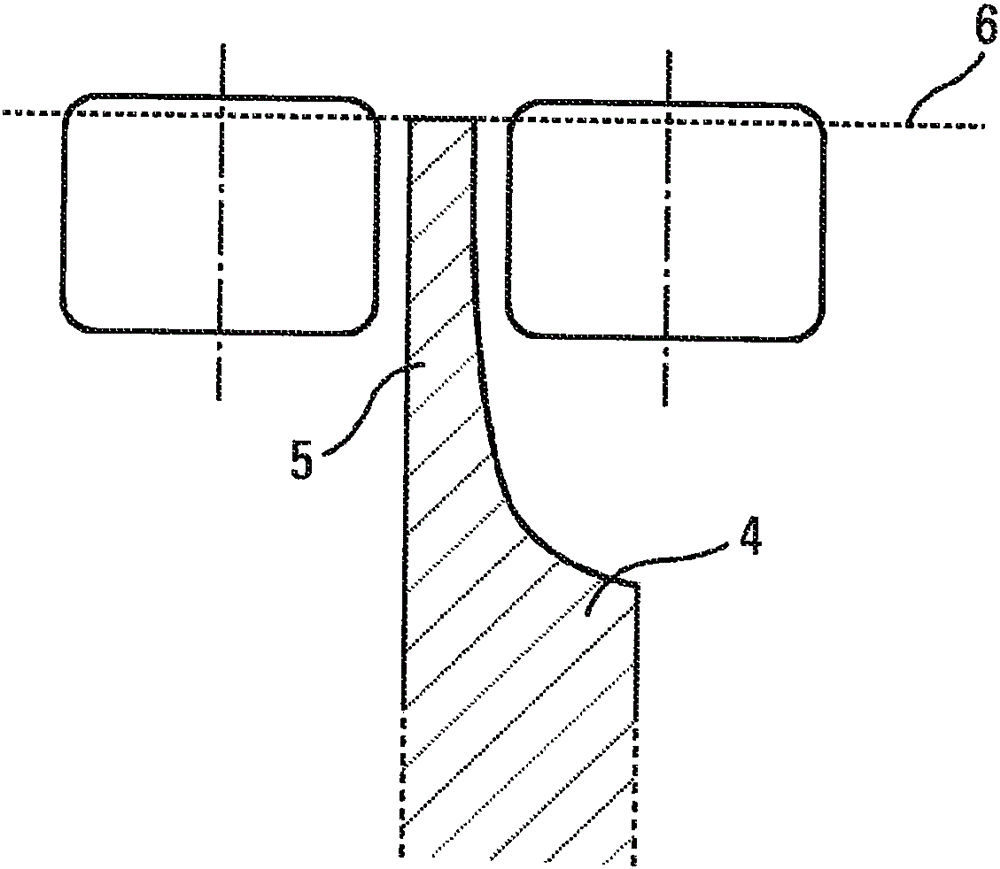

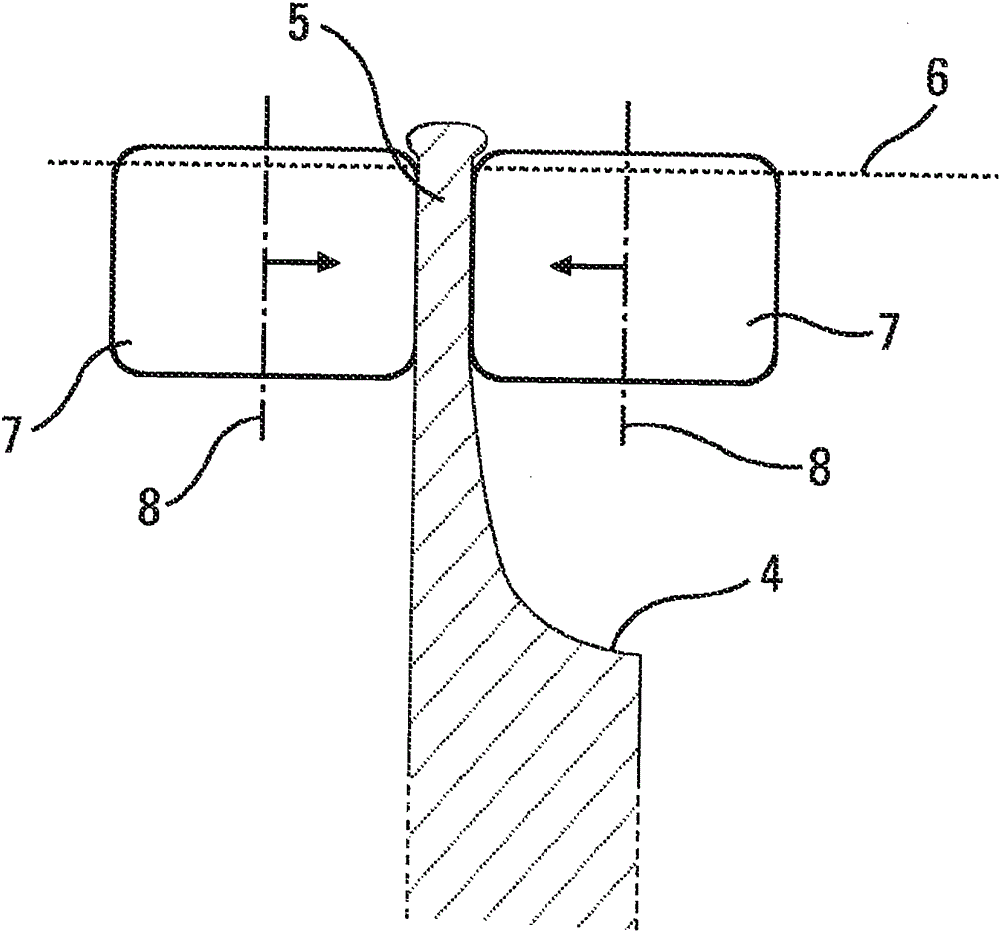

[0022] refer to figure 2 , which is a radial cross-section of the blade tip, the shape of the blade tip is a sharp edge 4, the thickness of which is determined by the expected mechanical strength characteristics, and its radial extension has a thinner part 5, which is called a groove by those skilled in the art The tip, the grooved tip acts to form a seal against the casing surrounding the compressor. This thinning of the groove tip is such that it inadvertently penetrates into the abradable material to which the casing is incorpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com