Method for increasing final electromagnetic stirring intensity of continuous casting billets

A terminal electromagnetic stirring and electromagnetic stirring technology, which is applied in the field of metallurgical smelting and rolling, can solve the problems of uneven surface temperature, affecting the magnetic field distribution in the stirring area, and stirring failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

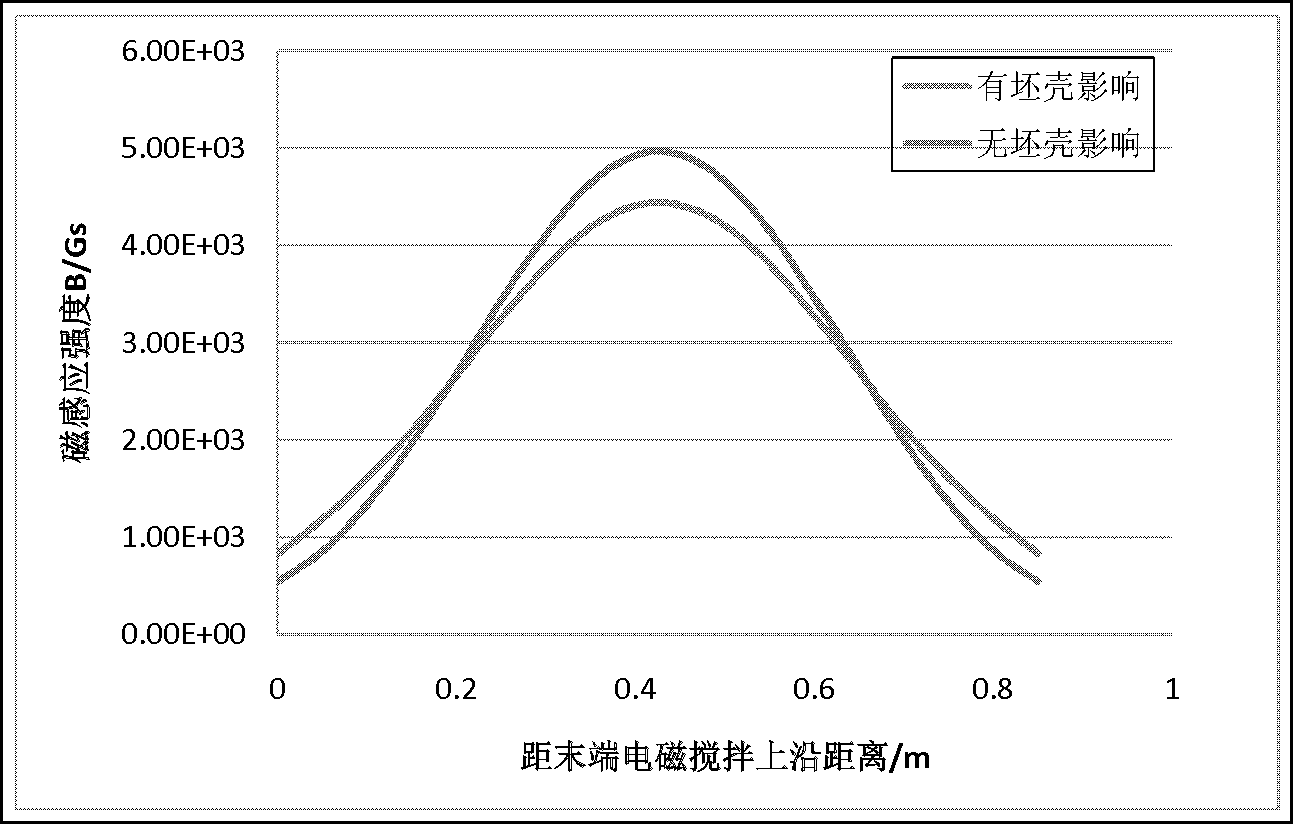

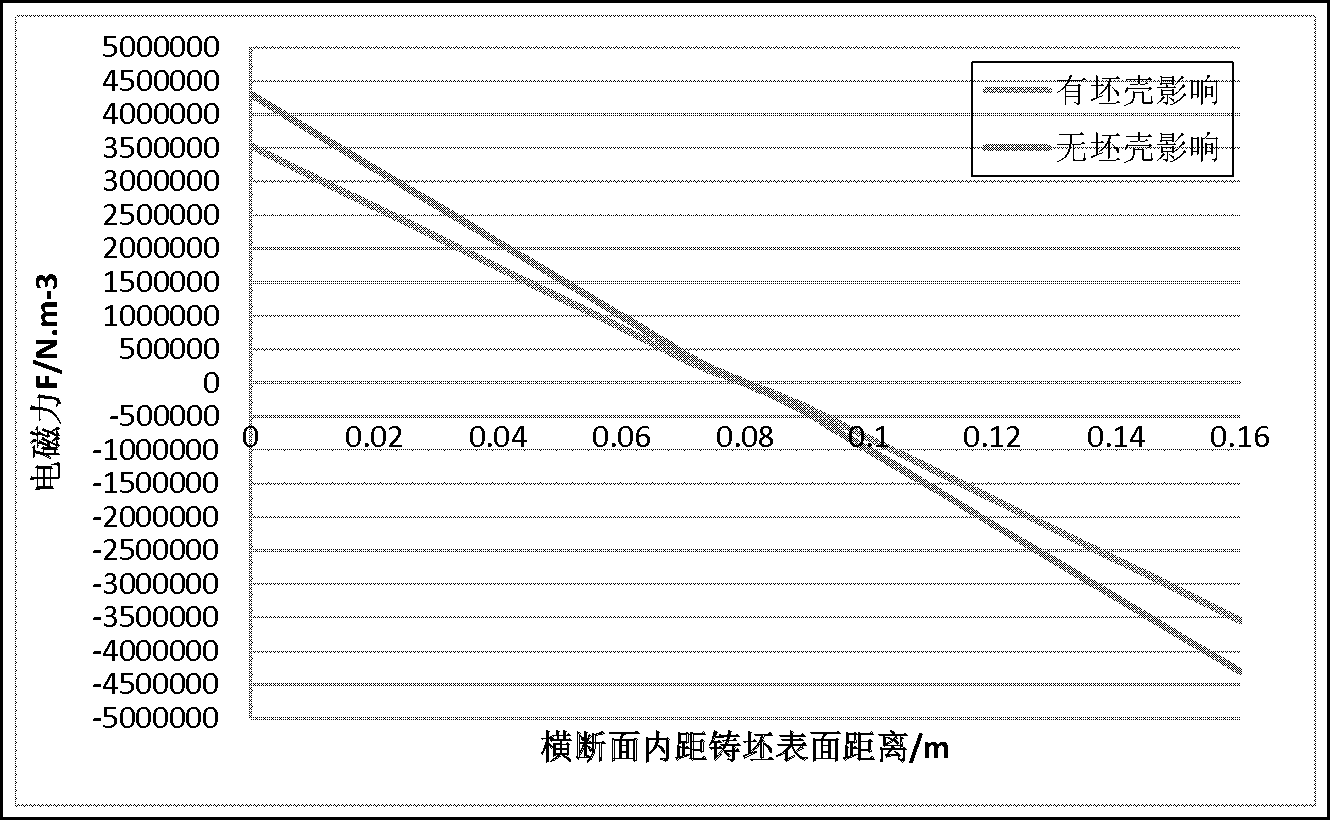

[0020] In actual on-site production, the control of the surface temperature of the continuous casting slab is unstable. With the change of the casting speed, the specific water volume and the superheat of the molten steel, the surface temperature of the slab will fluctuate, so there will be at the end electromagnetic stirring. In some areas, the phenomenon that the temperature is lower than the Curie point occurs. The Curie point of different steel types will be slightly different, but they are all around 770°C.

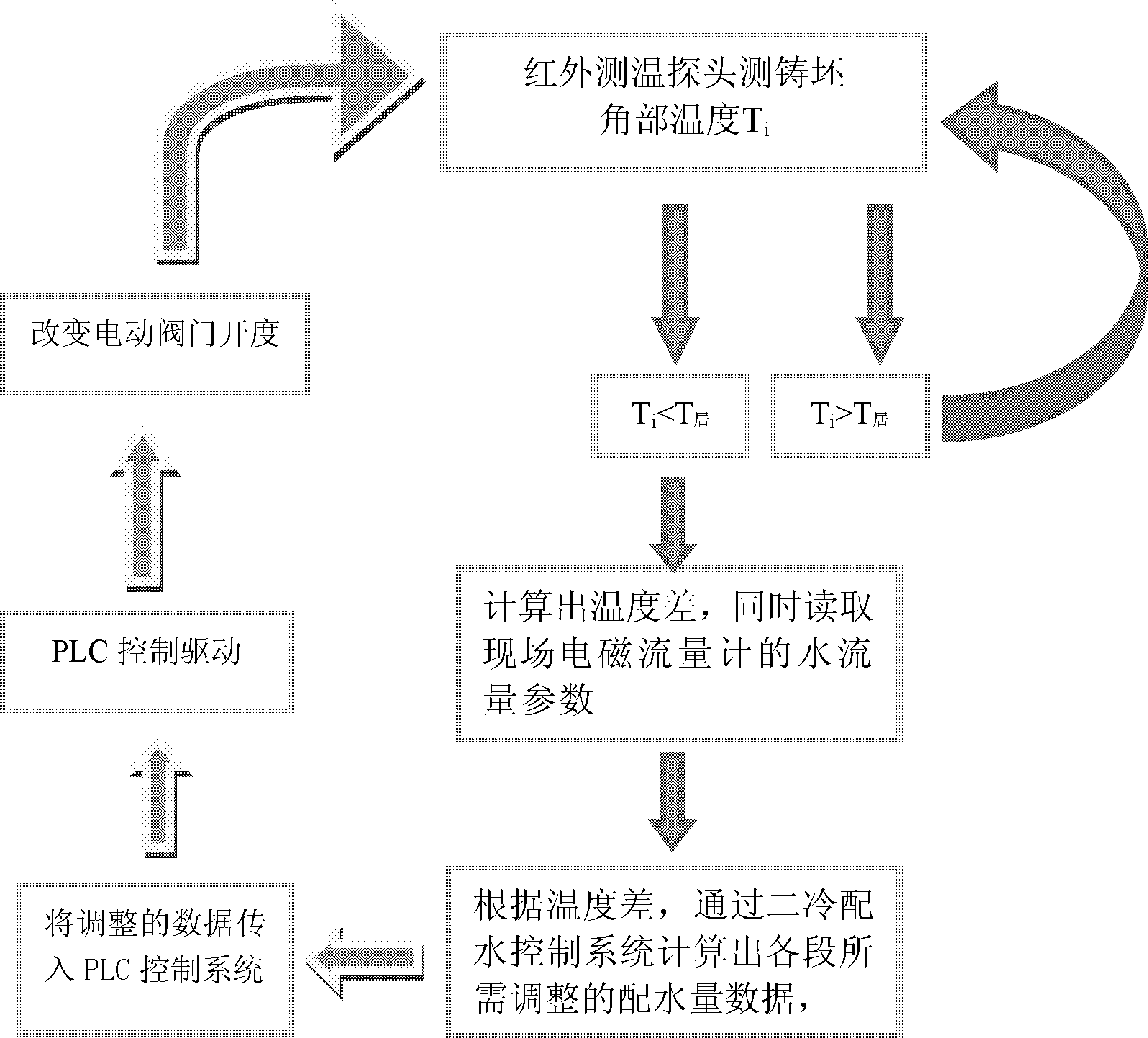

[0021] Such as image 3 Shown, the specific implementation steps of the present invention are as follows:

[0022] in such as Figure 4 , 5 In the position shown, around the electromagnetic stirring device, install and fix 8 infrared temperature measuring probes. The installation requirement is that the length direction of the infrared temperature measuring probe is perpendicular to one diagonal line of the billet cross-section, and the other diagonal line paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com