Partial outside surface shot blasting processing device of socket end of nodular cast iron pipe

A ductile iron pipe and treatment device technology, which is applied to used abrasive treatment devices, grinding/polishing equipment, abrasives, etc., can solve problems such as high cost, water leakage and water seepage at pipe interfaces, and save costs and space. , long service life, avoid water leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

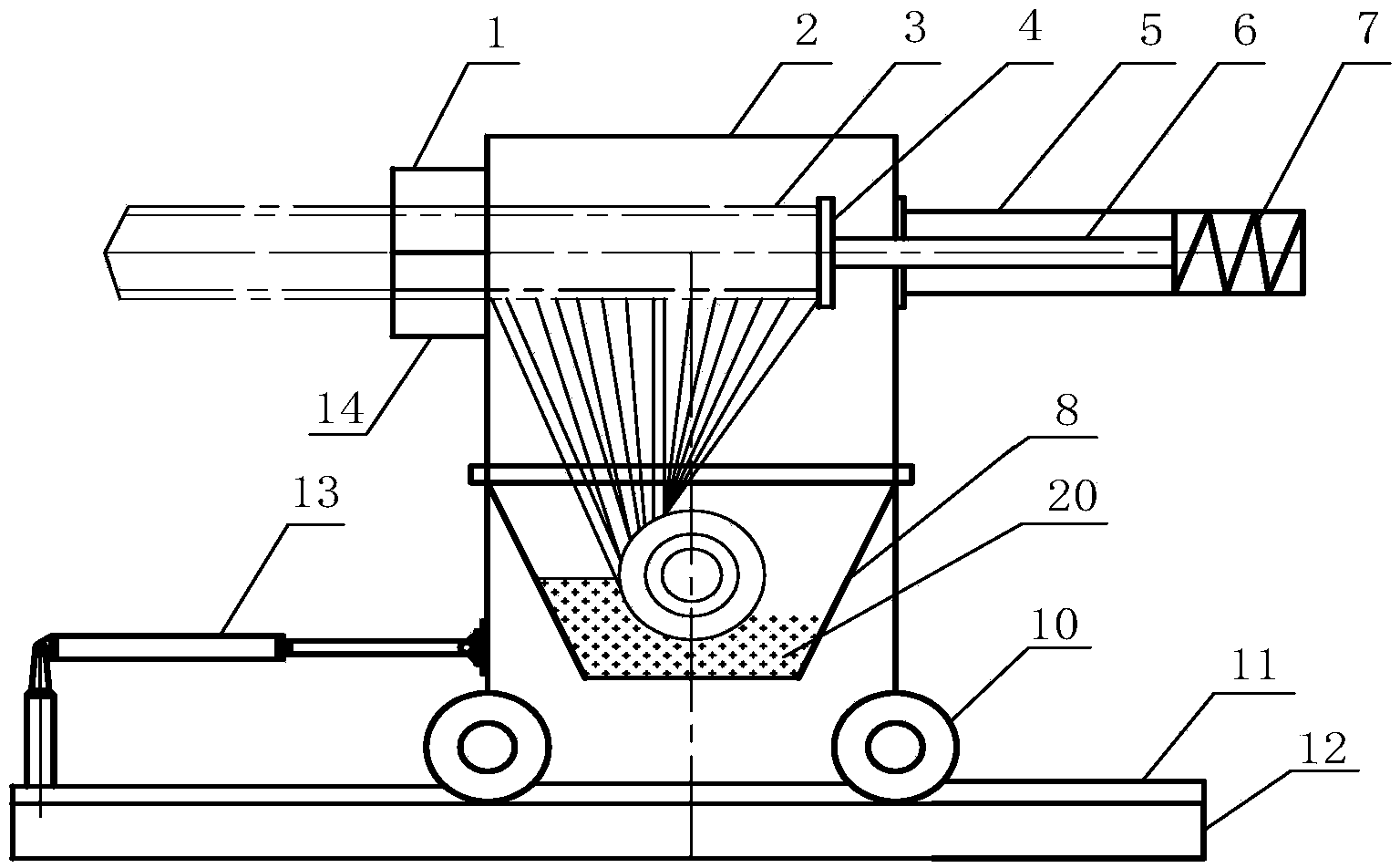

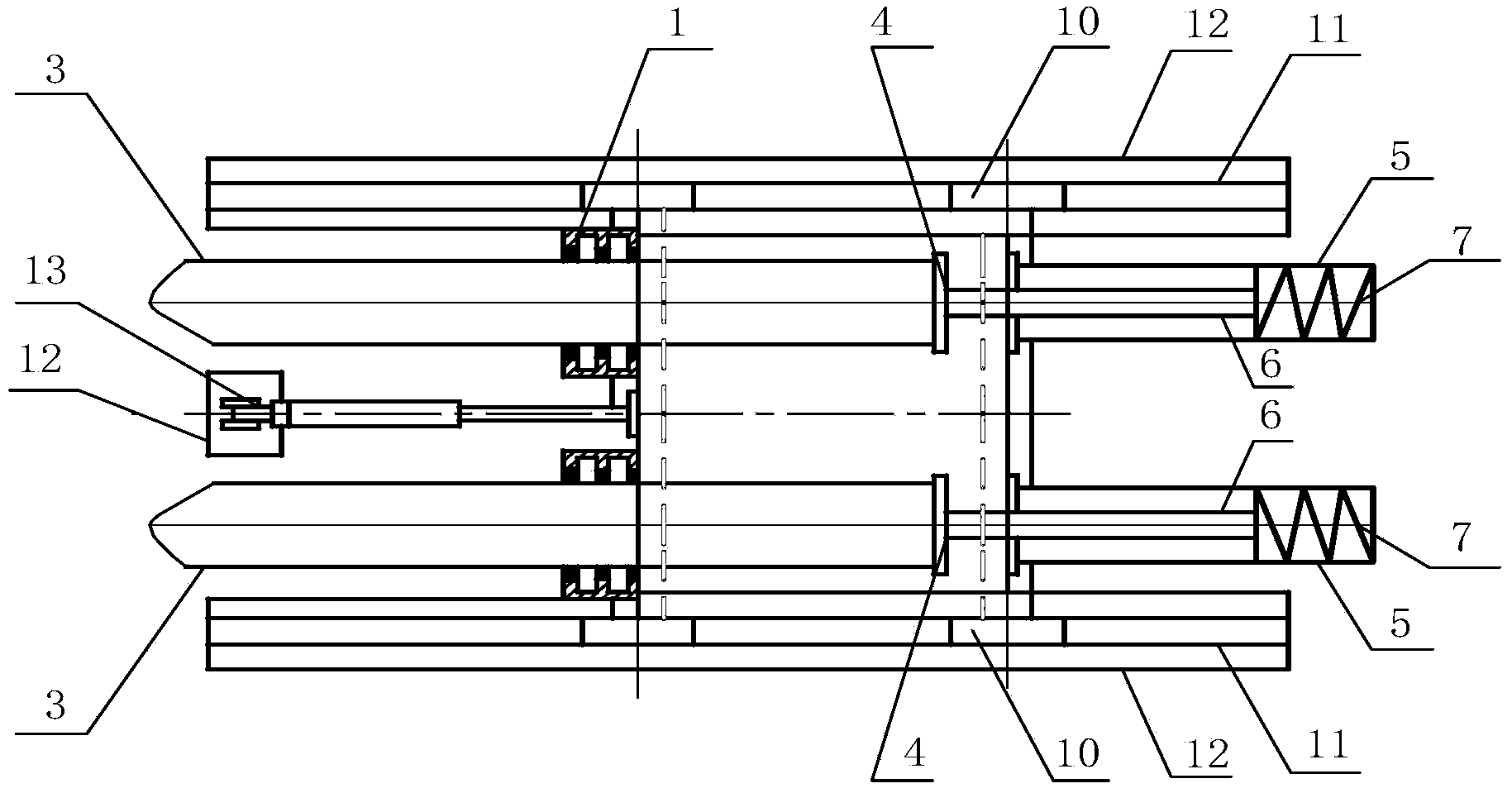

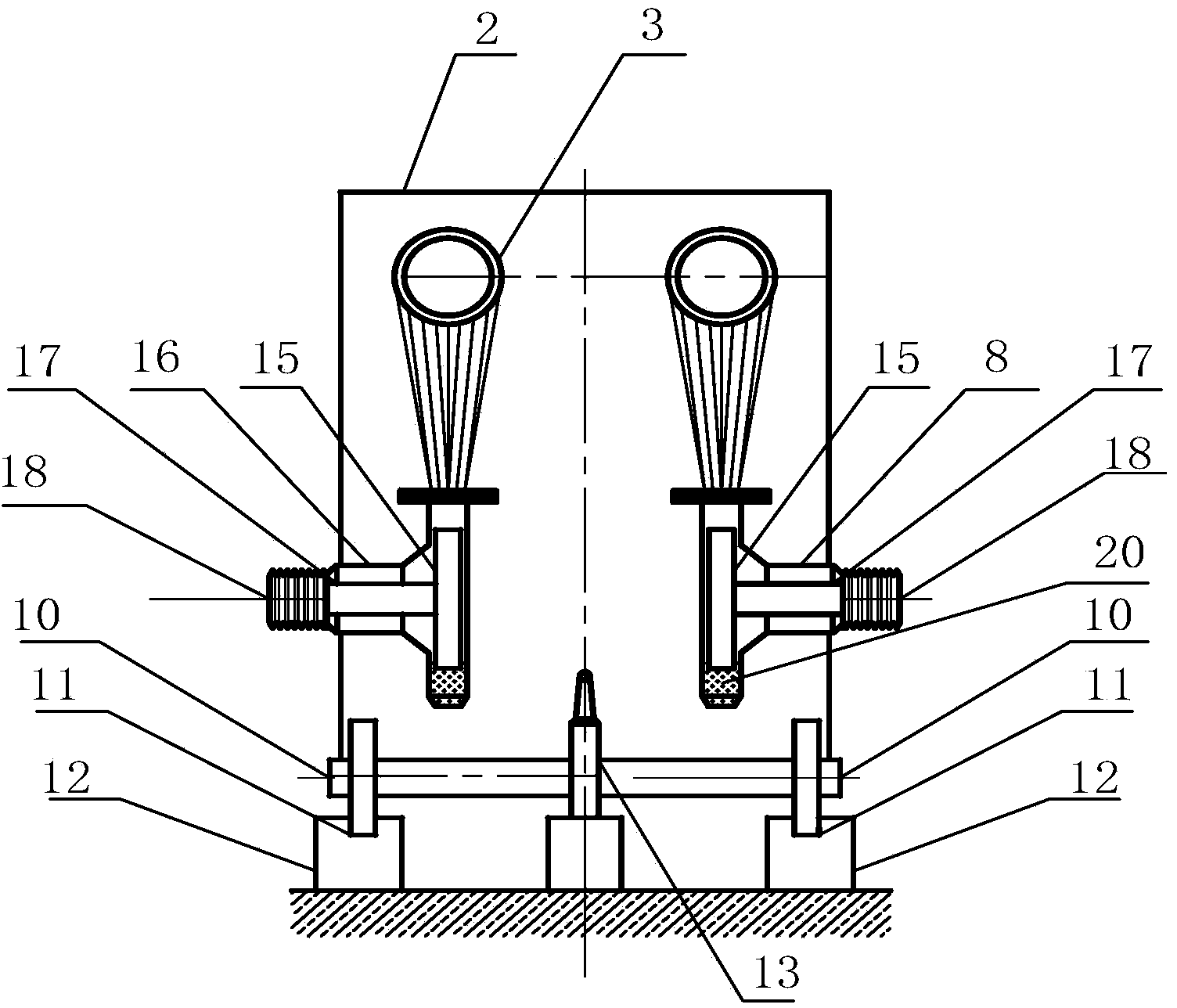

[0019] Such as figure 1 and 2 As shown, the shot blasting treatment device for the local outer surface of the spigot end of a ductile iron pipe of the present invention comprises: a trolley 10, a shot blasting chamber 2, two shot blasters 8, a cylinder 13, a nozzle sealing device 5, and a sealing ring on the pipe head 1 and the sealing ring 14 under the pipe head, the shot blasting room 2 is fixed on the trolley 10, and the trolley 10 walks on the slide rail 11 of the roadbed 12, and the shot blasting room 2 is equipped with two along the width direction of the shot blasting room 2 The shot blasting device 8 is placed symmetrically in parallel. The shell of the shot blasting device 8 is a trapezoid with a large upper end and a small lower end. Each ductile iron pipe 3 is inserted in the shot blasting chamber 2 above a shot blaster 8, one end of the cylinder 13 is fixed on the roadbed 12 in the center of the width direction of the trolley 10, and the other end is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com