Spinning winder

A winding machine and spinning technology, which is applied in the field of spinning and winding machines, can solve the problems of heating roller spinning-in difficulty and spinning-in difficulty, and achieve the effect of improving spinning workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

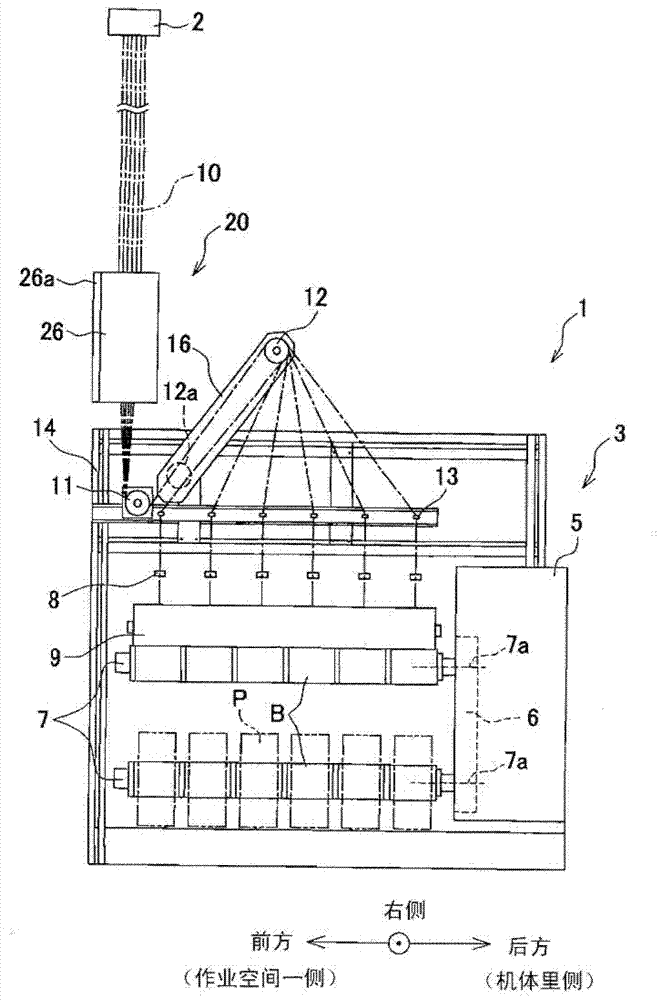

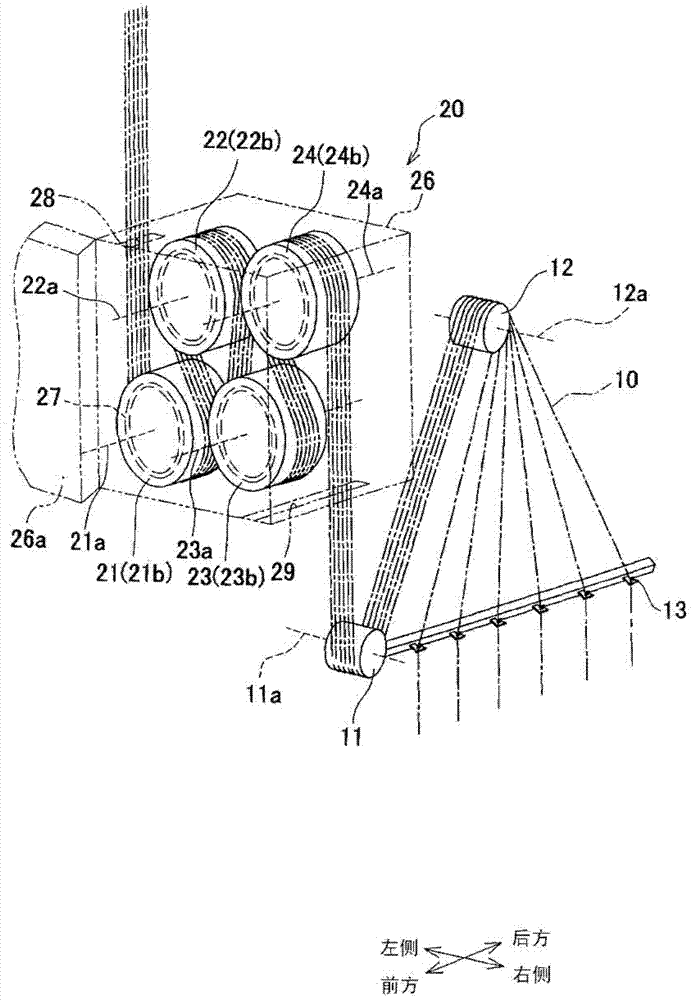

[0028] Next, embodiments of the present invention will be described. figure 1 It is a side view of the spinning winder of this embodiment. like figure 1 As shown, the spinning winder 1 sends a plurality of filaments 10 continuously provided by spinning from the spinning machine 2 located above to the winding below through the godet roller group 20 and two guide rollers 11 and 12. The unit 3 is wound with the winding unit 3 .

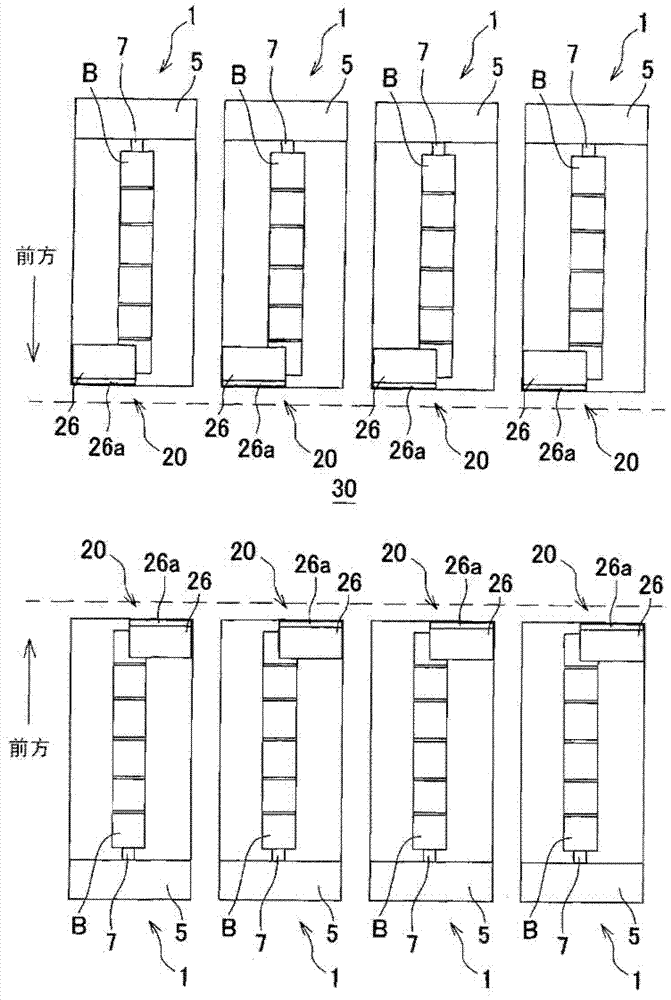

[0029] figure 2 It is a plan view illustrating the arrangement of a plurality of spinning winders. like figure 2 As shown, a plurality of spinning winders 1 are considered to be, for example, a plurality of nozzles for spinning a plurality of filaments 10 of the spinning machine 2 on the upstream side (upper side) of the spinning running direction than the spinning winder 1 . head arrangement, etc., or after taking out a plurality of bobbins B from the front end side of a bobbin holder 7 described later supported by a cantilever, it is necessary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com