Method for evaluating abrasion resistance of lubricating oil based on ball disc abrasion online monitoring and device

An evaluation method and lubricating oil technology, applied in measuring devices, suspension and porous material analysis, particle suspension analysis, etc., can solve problems that cannot reflect the anti-friction characteristics of lubricating oil, and achieve convenient operation, easy implementation, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

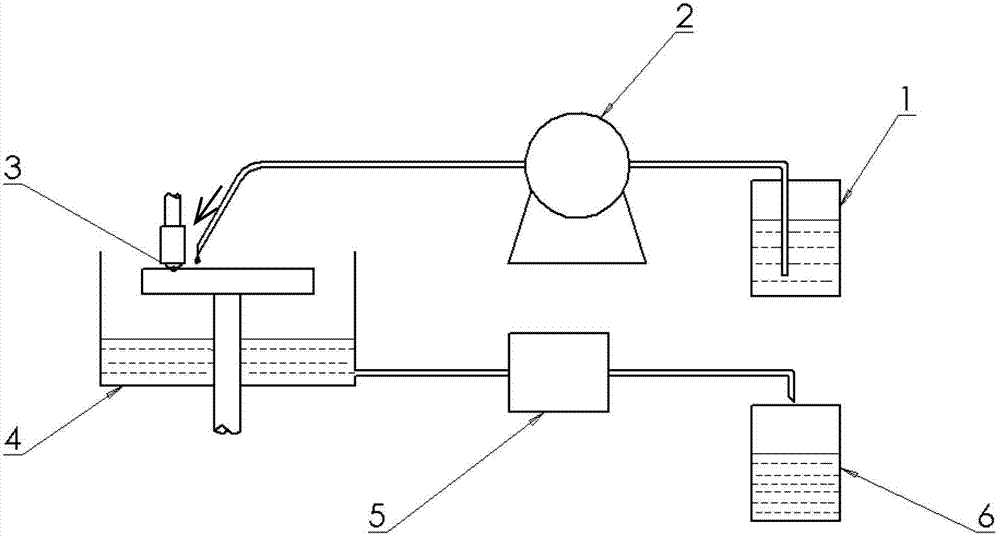

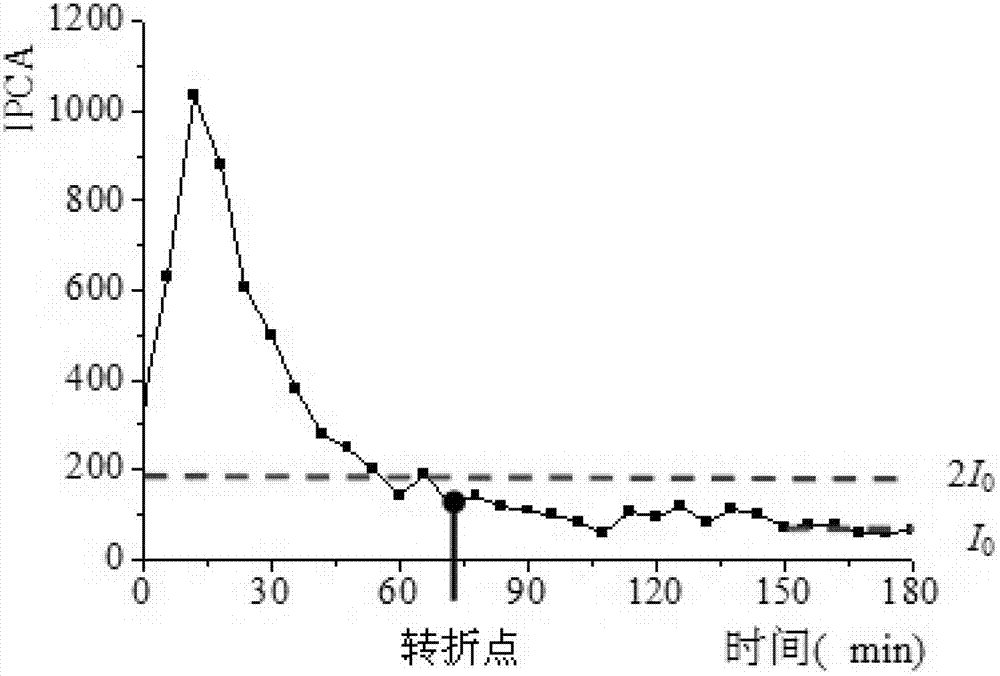

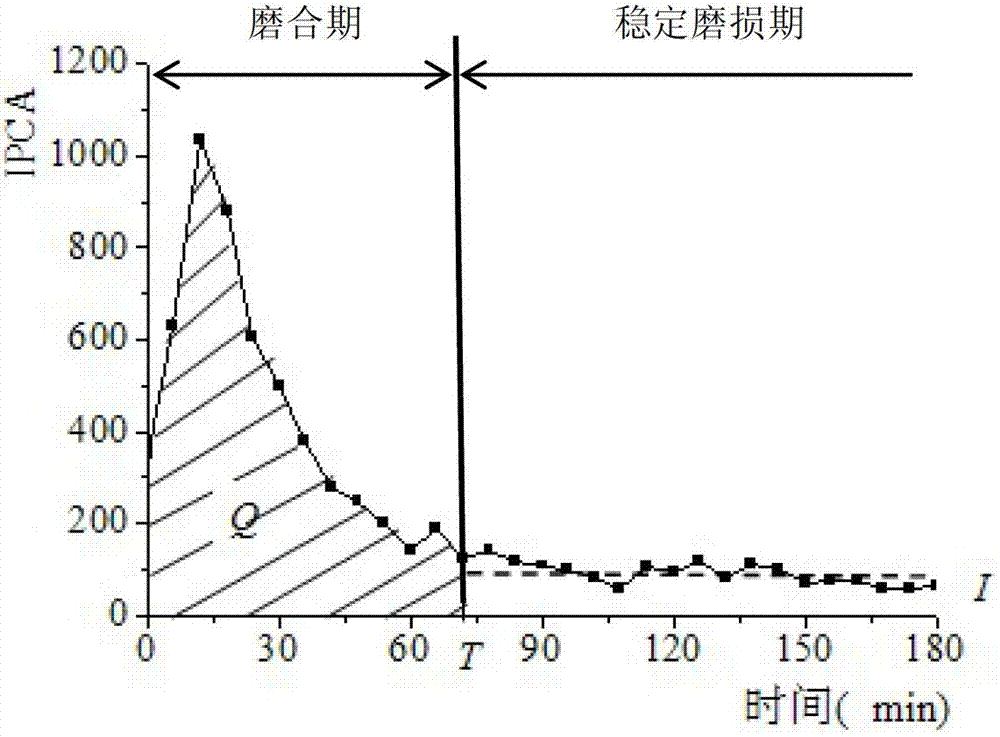

[0018] The present invention is based on the evaluation method of lubricating oil wear resistance on-line monitoring of ball-on-disk wear, which monitors the concentration of abrasive grains in the lubricating oil when the ball-on-disk friction pair of a pin-on-disc wear machine is in a boundary lubrication state in real time through an online image visual ferrography instrument. , to evaluate the anti-wear properties of lubricating oils. It includes the following specific steps:

[0019] 1) Supply oil to the ball-disk friction pair according to the set flow rate, and start the online image visual ferrography at regular intervals to sample and deposit the lubricating oil flowing through the ball-disk friction pair, and obtain wear particle deposition from the online image visual ferrography Picture; at the same time, the oil circuit of the online image visual ferrography instrument is flushed, and the oil supply to the ball-disk friction pair is equal to the sum of the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com