Line press component of hole check apparatus for assembling harness cord

A technology of eye correction and line creasing, applied in metal processing equipment, healds, manufacturing tools, etc., can solve problems such as low efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

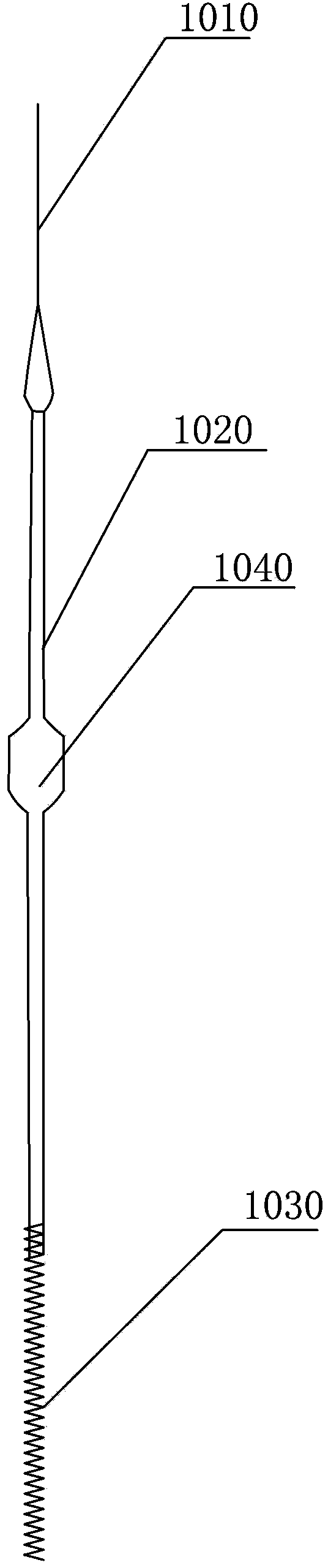

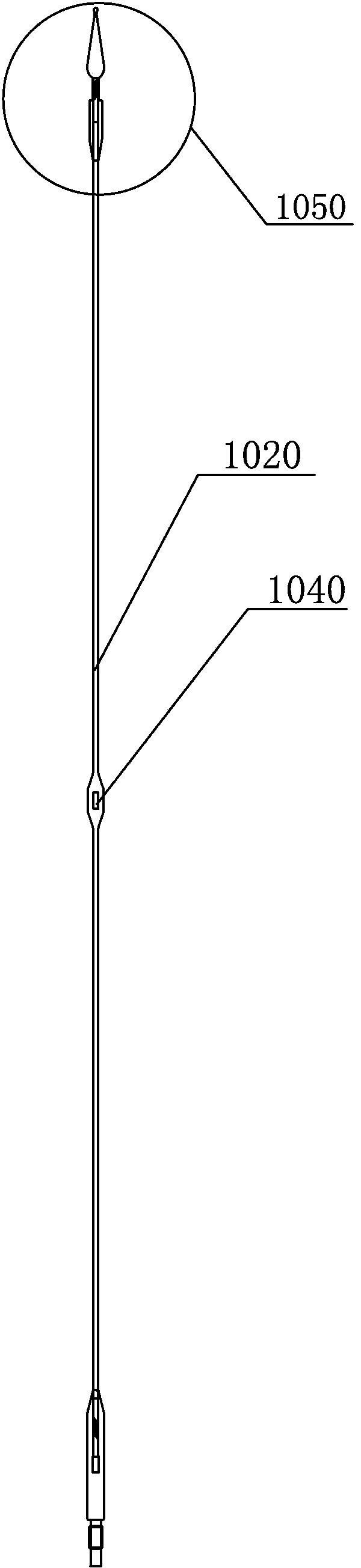

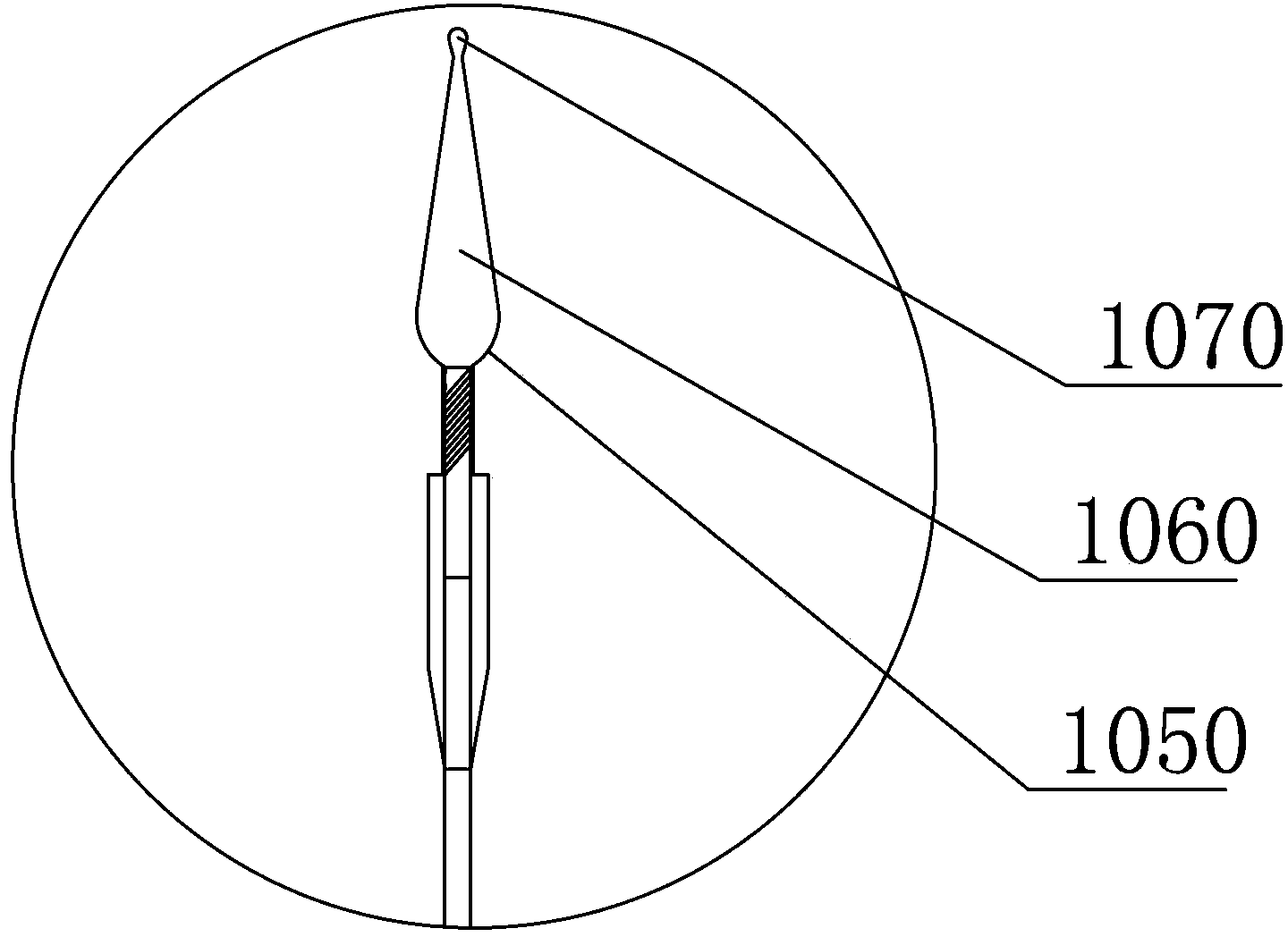

[0031] The crimping part of the present invention is installed on the school eye equipment, such as Figure 4 , 5 The eye-checking equipment includes a tooling base 100, which is provided with tooling parts, hook line parts, crimping parts, and secant parts on the tooling base 100. The tooling parts include a sleeve fixing template 11 arranged on the tooling base 100, and Fixed formwork 11 comprises base formwork 36, lower formwork 35 and upper formwork 32, and base formwork 36, lower formwork 35 and upper formwork 32 are all provided with a plurality of casing grooves 23 that vertically arrange, and the top, bottom and bottom of sleeve pipe like this All can snap into sleeve pipe groove 23 and fix, upper template 32 is provided with upper bolt 27, upper template 32 both sides are provided with upper latch fixing frame 31; Lower template 35 is provided with lower latch 29, lower template 35 both sides are provided with lower bolt fixed frame 33; Connect by bolt connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com