Methods, apparatus, and systems for UV gel ink spreading

An extension method, gel ink technology, applied in the field of ultraviolet (UV) curable gel ink extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

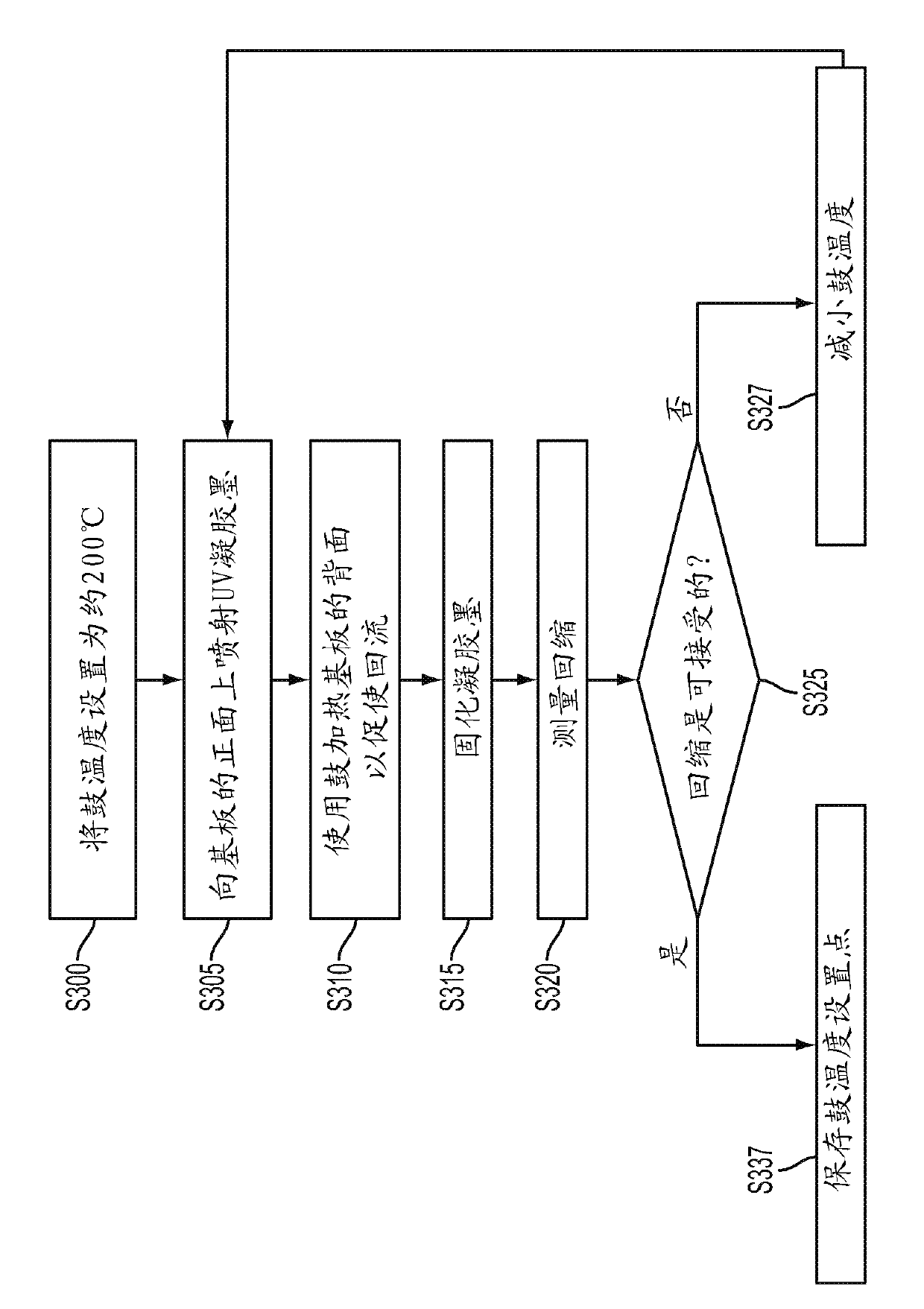

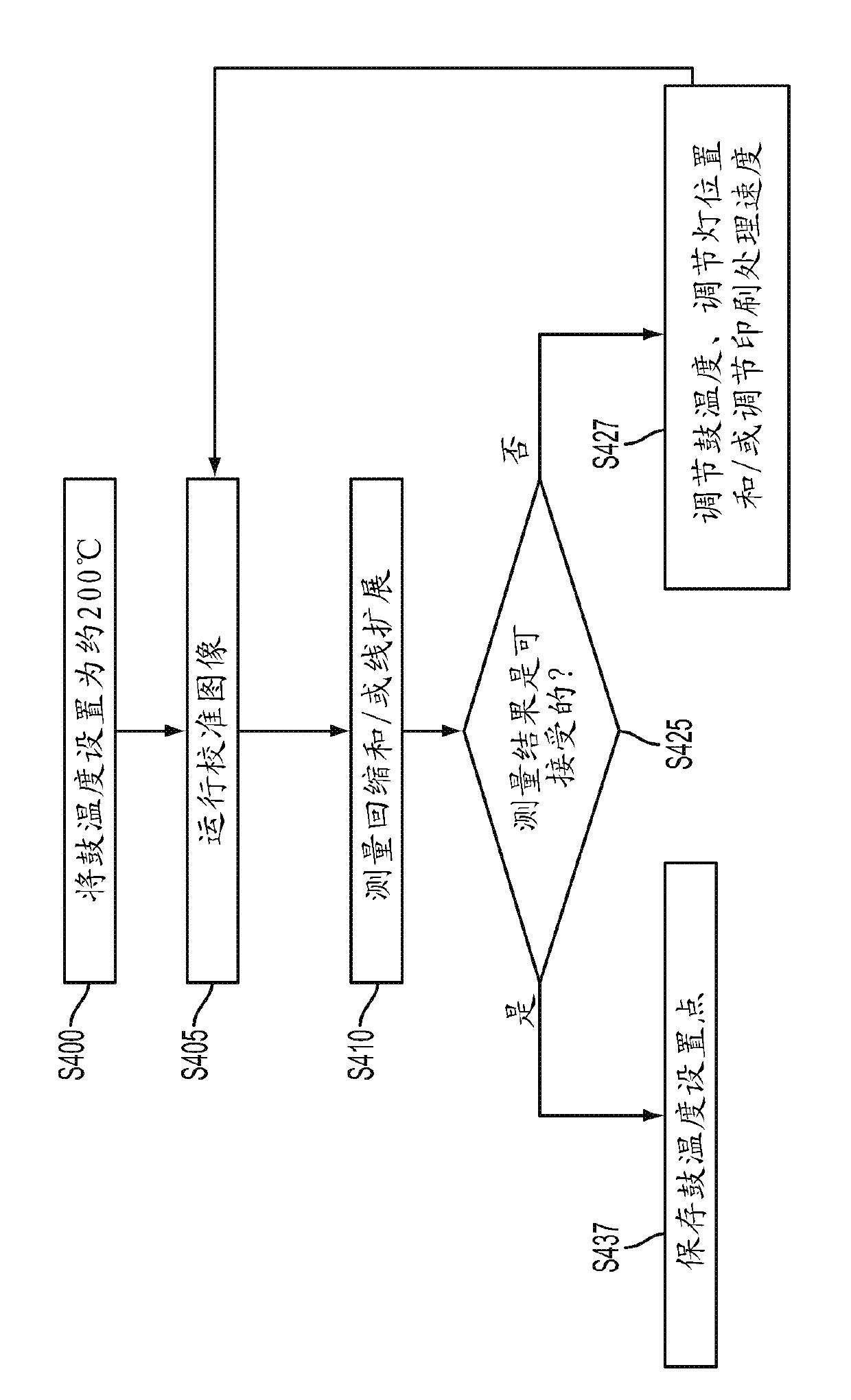

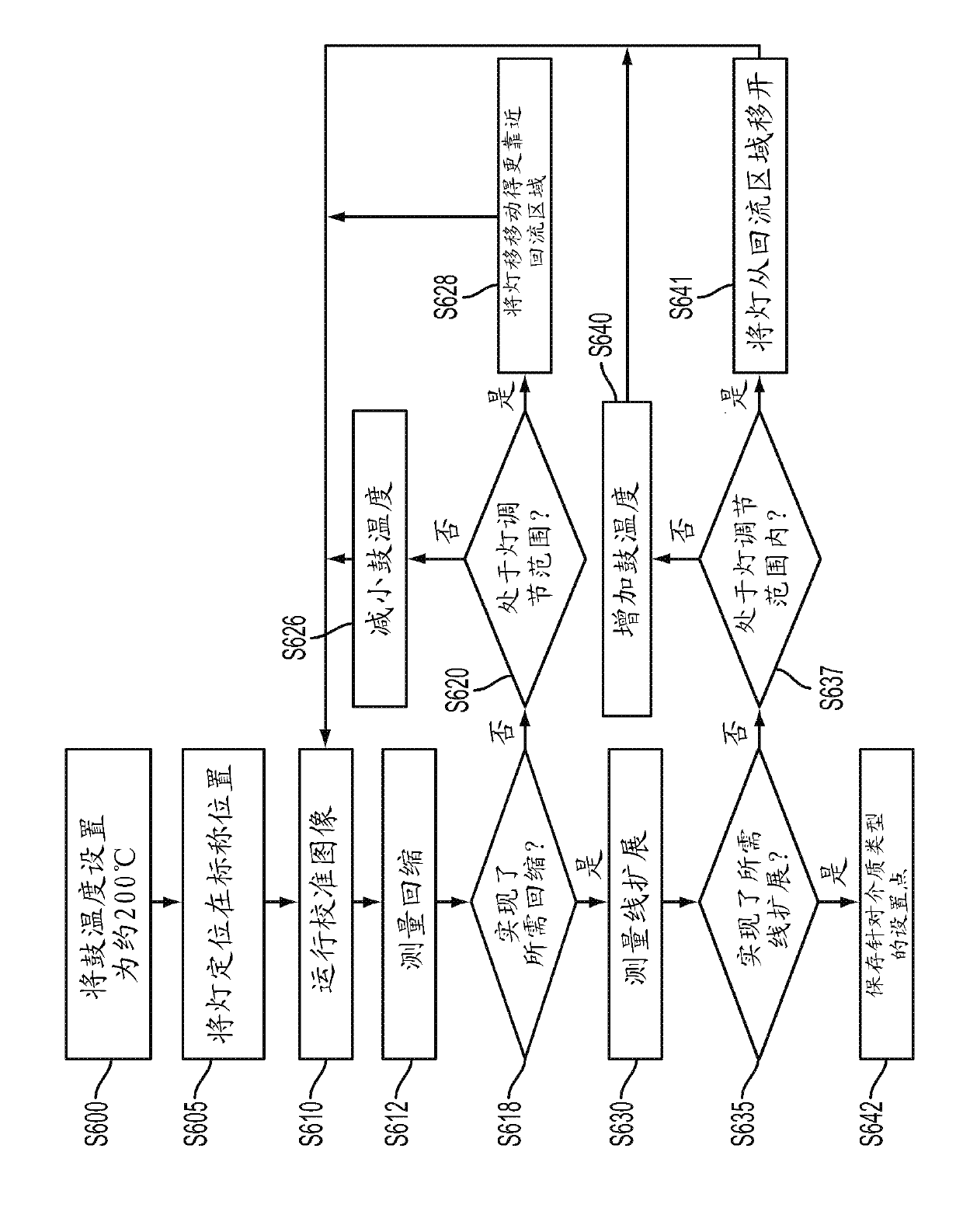

[0018] In order to produce acceptable digitally printed gel ink images using an inkjet printhead configured to directly jet ink onto a substrate, such as a media web, the pile height of jetted ink droplets can be monitored and analyzed. Observation of the build height of a particular substrate type relative to, for example, a paper media web of a particular thickness can be used to adjust system parameters to minimize image artifacts caused by, for example, non-uniform ink drop build thickness, or through non-uniform or unacceptable build height. A corduroy-like appearance formed by adjacent inkjet lines.

[0019] Parameters that can be adjusted include the temperature of a heated reflow assembly that directly contacts and heats the backside of the substrate, which conducts heat to the gel ink jetted to the gel ink image on the opposite image-bearing or front side of the substrate. The heated reflow assembly applies heat to the backside of a substrate, such as a media web, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com