A Pneumatic Expansion Clamping Mechanism

A technology of locking mechanism and outer bushing, which is applied in building structures, non-mechanical transmission-operated locks, building locks, etc., can solve problems such as limited support and inability to truly simulate the working state of car locks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

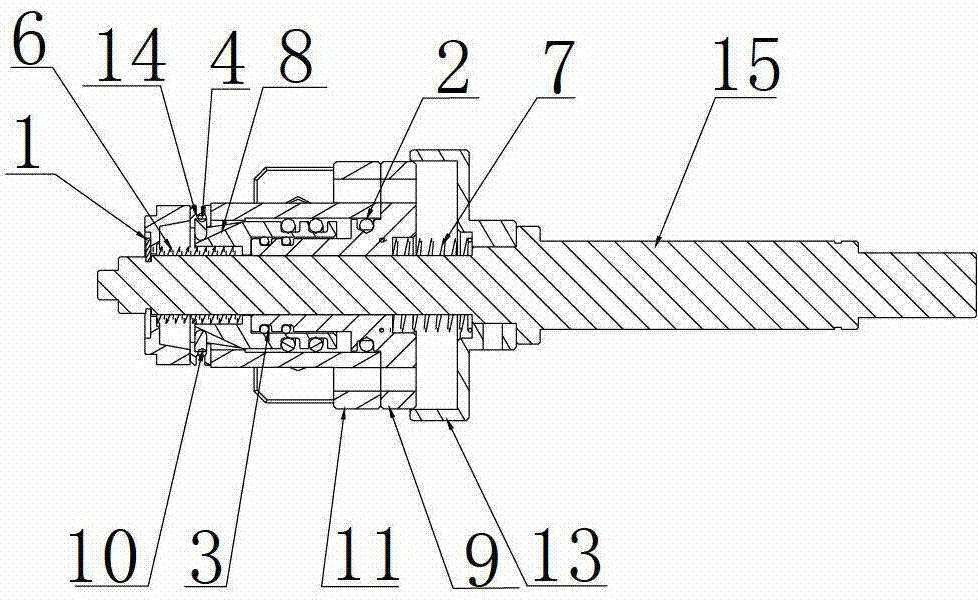

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

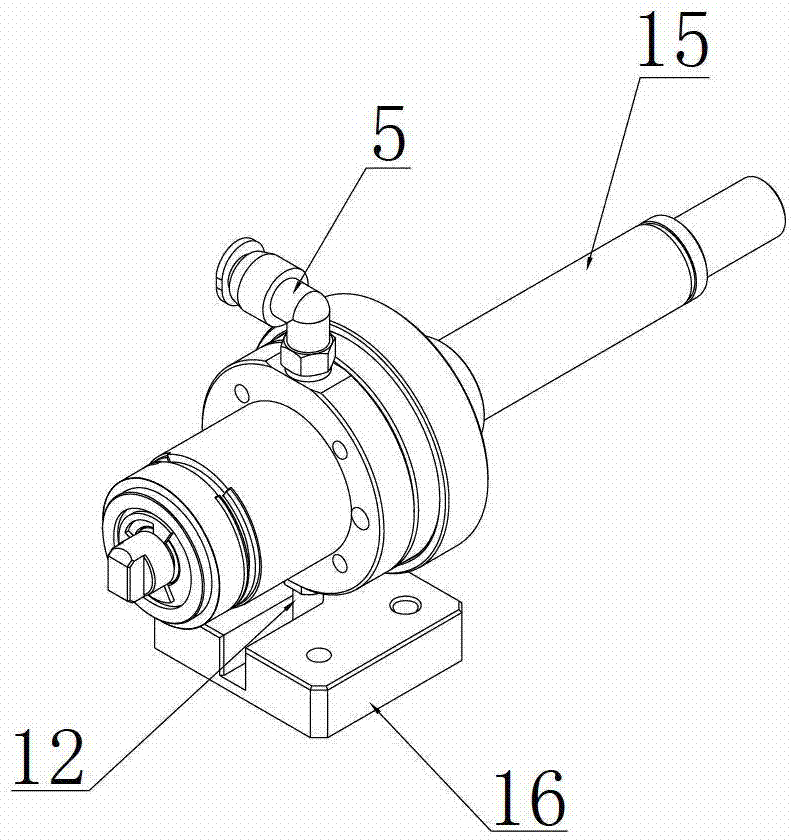

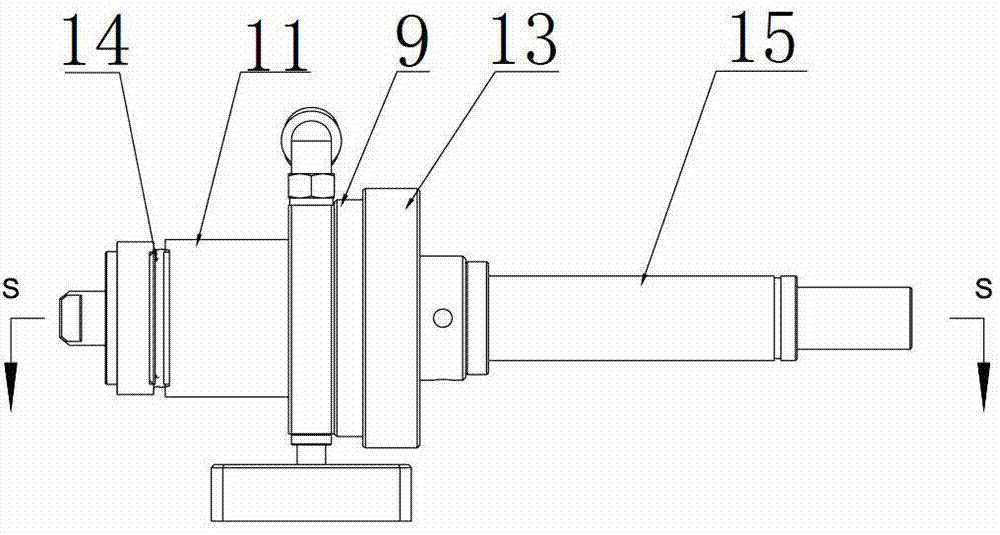

[0012] A kind of pneumatic expansion locking mechanism provided by the present invention, refer to figure 1 , figure 2 and image 3 , which includes a rotating shaft 15, an outer shaft sleeve 11, a rear base 9, a spring protection cover 13, a wedge-shaped shaft sleeve 8, a spherical pin 10, a shrapnel 14, and a guide plate 16; the rear base 9, the outer shaft sleeve 11 are installed on the rotating shaft 15 And the spring protection cover 13, the rear base 9 is located between the outer shaft sleeve 11 and the spring protection cover 13; the rear base 9 and the outer shaft sleeve 11 are fixedly sealed and connected by the sealing ring 12, and a spring protection cover 13 and the rotating shaft 15 are provided with Spring one 7; Spring two 6 is arranged between the rear base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com