Braking Performance Simulation Method and Device for Hydraulic Retarder

A hydraulic retarder and performance technology, which is applied in the field of hydraulic retarder braking performance simulation, can solve problems such as errors, imperfections, and non-convergence of calculation, so as to save workload, reduce dependence, and reduce calculation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

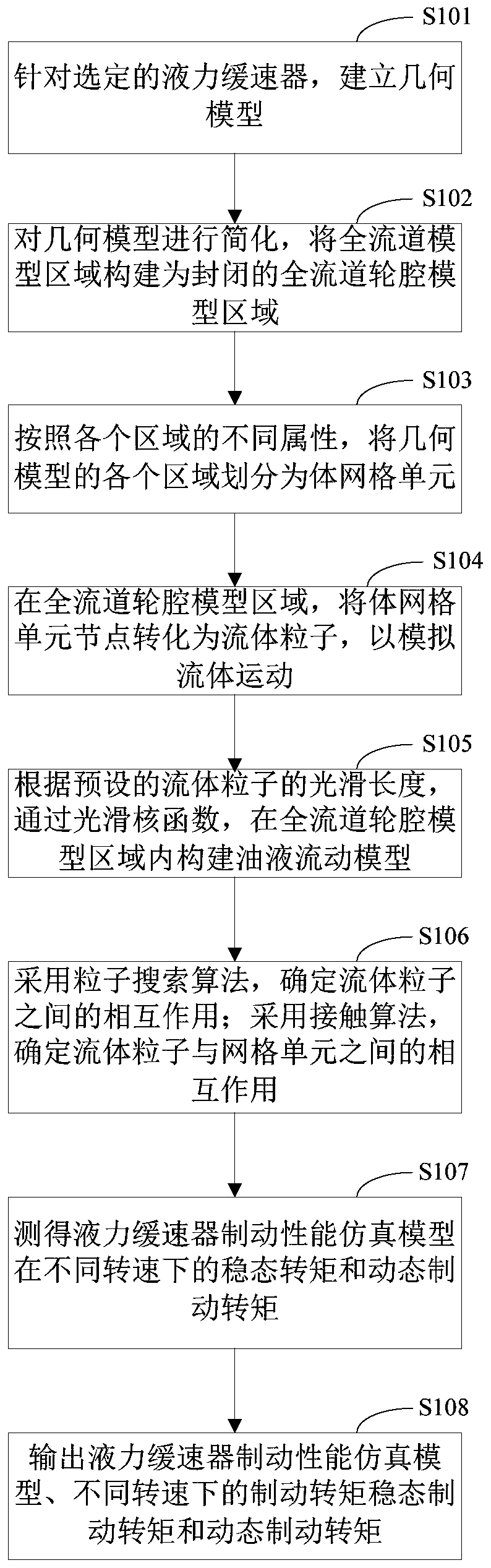

[0062] This embodiment provides a hydraulic retarder braking performance simulation method, such as figure 1 shown, including the following steps:

[0063] In step S101, a geometric model is established for the selected hydraulic retarder; the geometric model includes a fixed wheel model area, a moving wheel model area and a full channel model area.

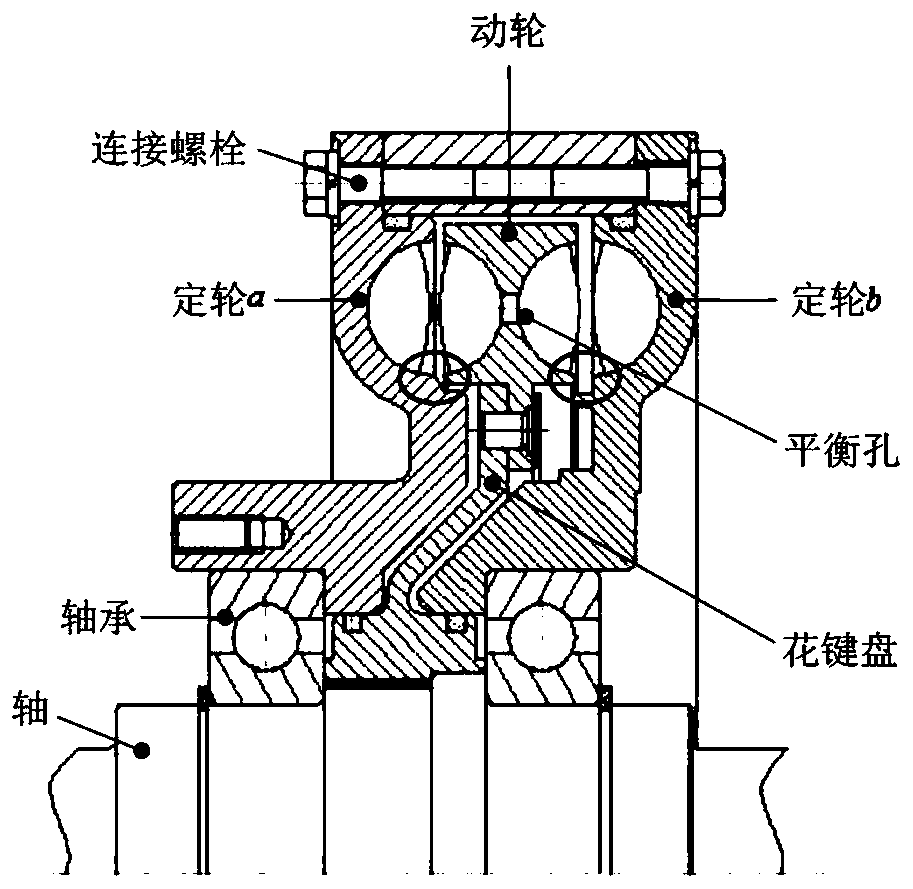

[0064] Taking a double-cycle circular hydraulic retarder as an example, it is mainly composed of two fixed wheels and a moving wheel. The number of blades of the fixed wheel is 51, the number of blades of the moving wheel is 47, and the diameter of the circular circle of the impeller is 355mm. According to the structure of the hydraulic retarder, a three-dimensional geometric model is established. There is one oil inlet and two oil outlets distributed in the area of the full channel model, that is, one oil inlet (fluid-filled branch) and two oil outlets ( circulation heat dissipation branch and liquid filling regulation branch...

Embodiment 2

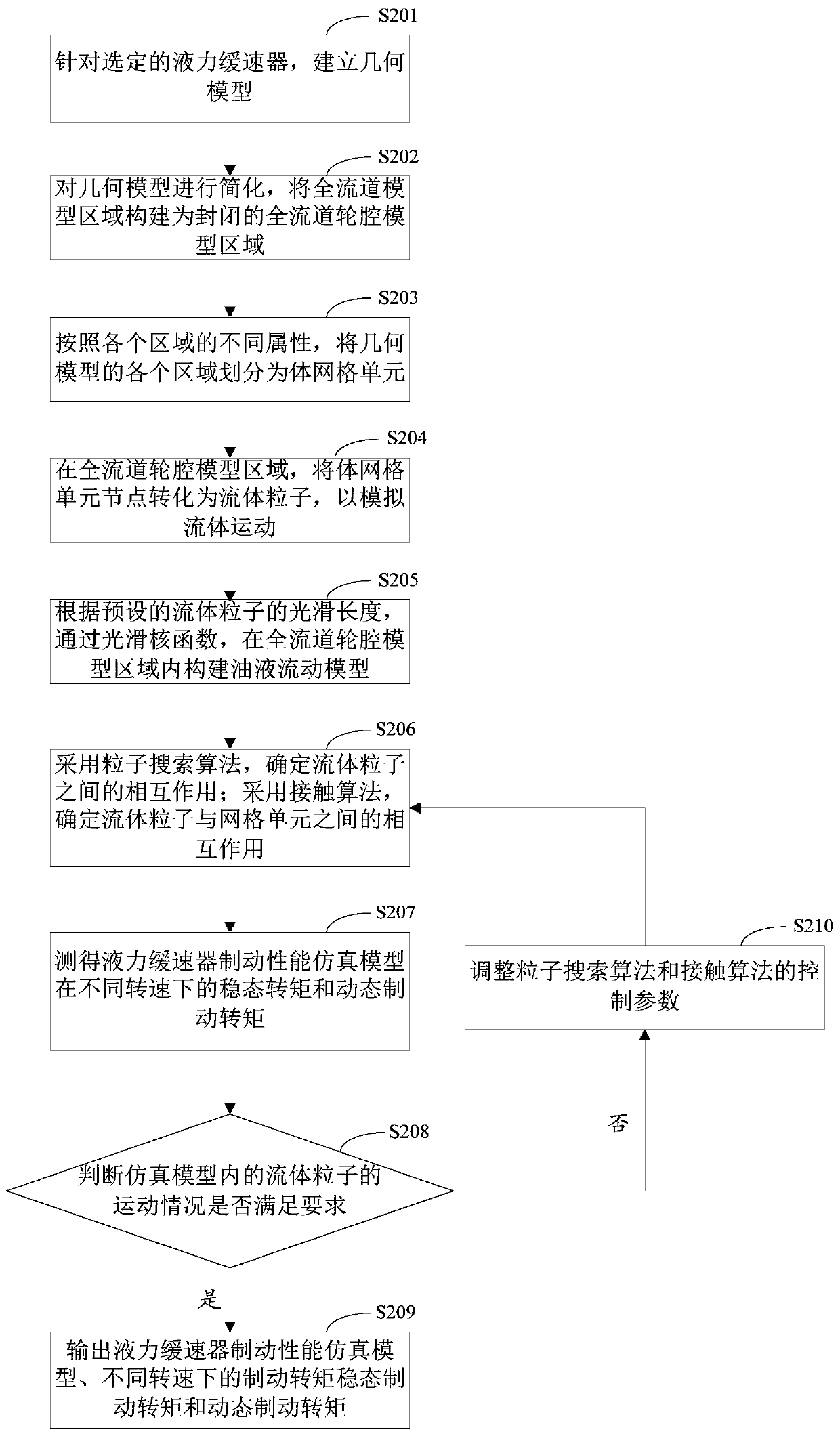

[0108] Such as figure 2 As shown, the hydraulic retarder braking performance simulation method provided in this embodiment includes the following steps:

[0109] Step S201, establishing a geometric model for the selected hydraulic retarder; the geometric model includes a fixed wheel model area, a moving wheel model area and a full flow channel model area;

[0110] Step S202, simplifying the geometric model, constructing the full-runner model area as a closed full-runner wheel cavity model area;

[0111] Step S203, dividing each region of the geometric model into grid units according to different attributes of each region;

[0112] Step S204, in the area of the full-channel wheel cavity model, convert the volume grid unit nodes into fluid particles to simulate fluid motion;

[0113] Step S205, according to the preset smooth length of the fluid particles, the oil flow model is constructed in the full channel wheel cavity model area through the smooth kernel function;

[01...

Embodiment 3

[0131] This embodiment discloses a hydraulic retarder braking performance simulation device, such as Figure 7 As shown, the device includes:

[0132] The geometric model building module 71 is used to establish a geometric model for the selected hydraulic retarder; the geometric model includes a fixed wheel model area, a moving wheel model area and a full runner model area; the geometric model is simplified, and the entire The runner model area is constructed as a closed full runner wheel cavity model area;

[0133] A grid division module 72, configured to divide each area of the geometric model into grid units according to different attributes of each area;

[0134] The particle generation module 73 is used to convert the body mesh unit nodes into fluid particles in the full channel wheel cavity model area to simulate fluid motion;

[0135] The simulation model construction module 74 is used to construct an oil flow model in the area of the full channel wheel cavity mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com