High-pressure pneumatic blasting pressure relieving and transmission increasing method

A technology of blasting pressure relief and high-pressure gas, which is applied in earthwork drilling, gas discharge, and mining fluids. It can solve problems such as potential safety hazards, complex processes, and large water volumes, and achieve improved gas extraction rates and low permeability. easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

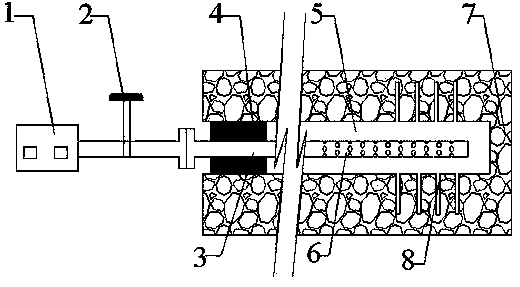

[0009] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0010] In the high-pressure pneumatic blasting pressure relief and anti-reflection method of the present invention, at first conventionally construct the blasting borehole 5 in the coal seam 7, and the depth of the blasting borehole 5 is 25-30m; The high-pressure water jet slotting operation is carried out at intervals from the inside to the outside, so that the coal body around the inside of the blasting borehole 5 forms equally spaced guiding slots 8; On the other hand, these slots and cracks can play a role in guiding and controlling, so that the high-pressure gas can concentrate and impact in several directions, the generation and penetration of cracks are better, and the blasting effect is better; The top-blocked blasting steel pipe 3 is fed into the hole 5, and a number of air holes 6 are opened on the outer wall of the front closed end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com