Washing machine and drying machine

A technology for washing machines and drying machines, which is applied to washing devices, other washing machines, washing machines with containers, etc., and can solve the problems of insufficient suppression effect and non-controlling of buffers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

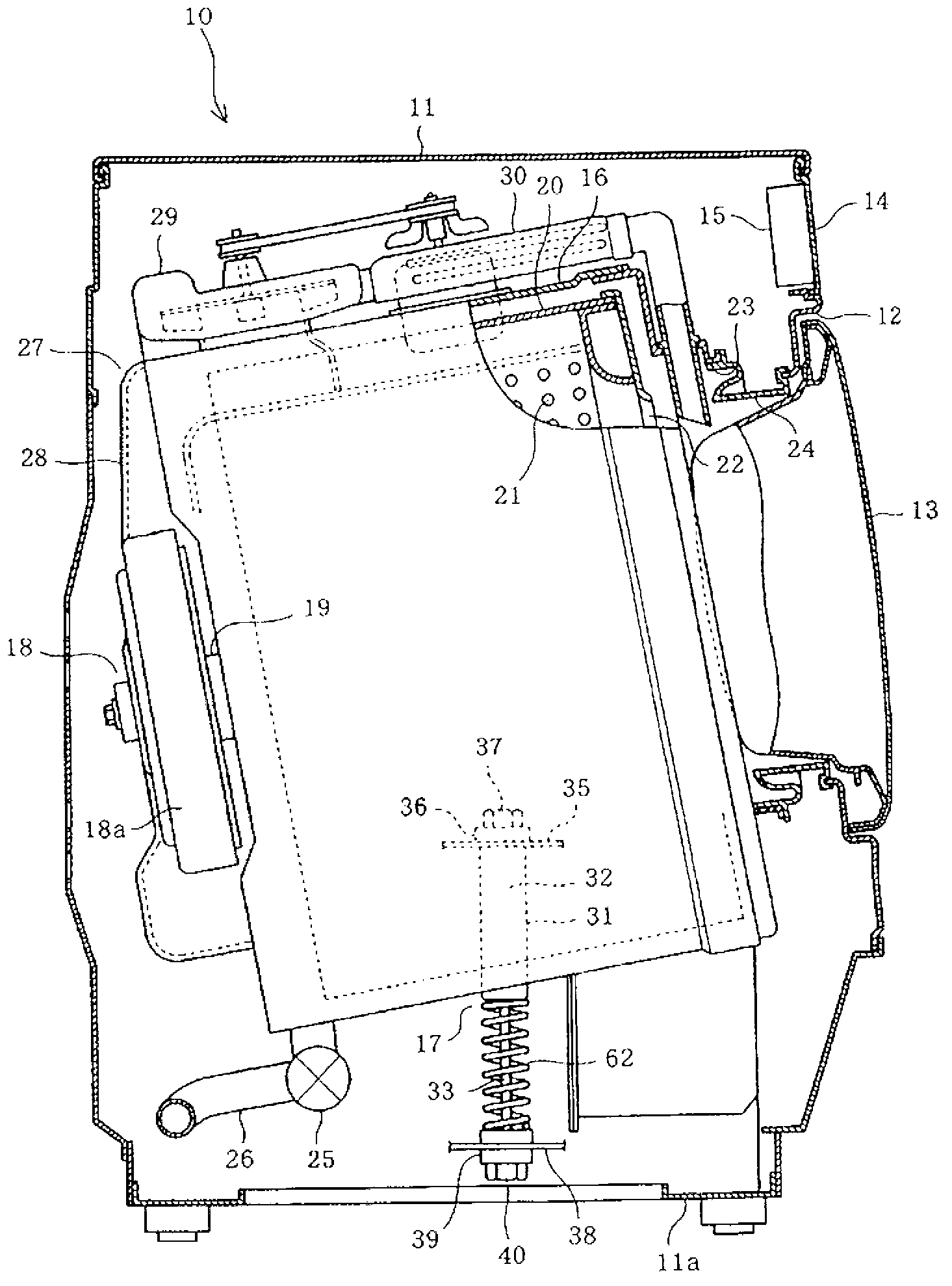

[0032] exist figure 2 In the illustrated drum type washing machine (hereinafter simply referred to as the washing machine 10), an outer case 11 formed as an outer casing has, at its front portion ( figure 2 The laundry entrance 12 is formed in a substantially central part of the middle right side), and a door 13 for opening and closing the entrance 12 is provided. An operation panel 14 is provided on the upper portion of the front portion of the outer case 11 , and a control device 15 for operation control is provided on the back side thereof (inside the outer case 11 ). In addition, on the bottom plate 11a of the outer case 11, a temperature detection device (the temperature detection part 67 described later, refer to Figure 4 ).

[0033] Inside the outer case 11, a water tank 16 in the shape of a horizontal axis cylinder is disposed. Tank 16, its central axis points to the front and rear direction ( figure 2 center, left and right), and is elastically supported on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap